High-Torque Street Engines

Widely regarded as one of the world's best Mopar engine men, Ray Barton is famous for his NHRA record-setting Super Stock Hemis. The fact is, he and the crew at Ray Barton Racing Engines (RBRE) also work wonders with wedge-head Mopars. The stroked 451 low-deck motor outlined here sports a mere 10.5:1 compression, a streetable flat-tappet camshaft, and mildly reworked aluminum Indy heads, yet it produces an astounding 673 hp at 6,900 rpm and 527 lb-ft of torque at 5,400 rpm.

RBRE assembled this tall-torque heavy for a well-heeled street performance enthusiast, and the tab came to about 11 grand. But that's because the customer insisted on the ultimate in reliability, hence the inclusion of premium parts. Similar performance can be achieved for significantly less money if the builder uses items like stock forged rods and iron Indy heads.

The core of the assembly is a decidedly mundane cast-iron low-deck 400 block pirated from a '73 Chrysler Newport. The motor's deep-skirt crankcase design is very rigid and can withstand up to 900 hp. With the crankshaft and rods from a raised-deck Chrysler big-block wedge (413, 426, or 440) and custom pistons with the proper pin height, the low-deck 400 expands to 451 cubic inches. The only sticking point is that the main bearing saddles of all low-deck blocks (Mopar 350s, 361s, 383s, and 400s) are machined to accept a crankshaft with 2.625-inch journal diameters; all raised-deck cranks maintain 2.750-inch main journals. The obvious solution would seem to be to turn down the 440 crank to fit the 400 block, but this modification severely compromises the strength of the crankshaft.

Barton took a better route. He mounted the 400 block in a Sunnen CK10 align-boring machine and enlarged all the main bearing saddles to 440 size. The 400 lower end has so much beef that this reduction practically goes unnoticed. Naturally, the main caps must match the block, so Barton simply plucked a set of 440-size RBRE On-Trac billet-steel caps off the shelf and secured them with ARP 1/2-inch studs.

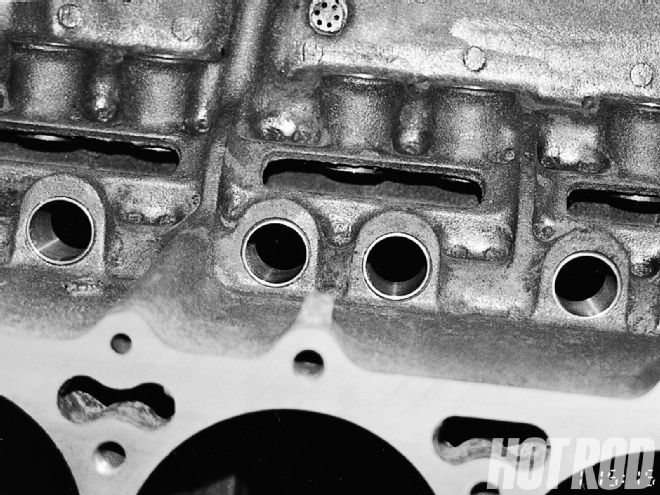

The next step is to enlarge the oil pickup tube to 1/2-inch Hemi specifications and use bronze bushings in the lifter bores to correct factory machining inaccuracies. This ensures the precise location of each lifter in relation to the cam and the crank. Barton has found that inaccuracies in some stock blocks can affect the cam timing of individual cylinders by as much as 15 degrees. To rectify the situation, a BHJ fixture attached to the block allows the lifter bores to be bored oversize and establishes a centerline and correct angularity. Then bronze bushings are pressed into place and honed to final size. This process is intended to ensure that each valve receives equal cam lift and duration, thereby balancing power between cylinders. It also enhances oil control by reducing bleed-off and enabling the block to maintain full oil pressure even if a failed pushrod allows the cam to bump a lifter out of its bore.

A stock forged-steel 440 crankshaft was treated to chamfered oil-transfer holes, careful polishing, and fully grooved Clevite 77 Hemi-spec bearings. However, stock Chrysler big-block connecting rods, while forged, are not very reliable at power levels beyond 500 or when the crankshaft speed exceeds 6,500 rpm. In their place, we find RBRE On-Trac 4340 forged-steel units prepared with shot-peened beams and ARP 3/8-inch Wav-Loc bolts. The small ends are bushed and receive big-block-Chevy-size (0.990-inch diameter) full-floating RBRE On-Trac tapered wall pins for a substantial weight reduction over stock parts.

When you consider that 440 blocks have taller cylinder bores than 400 blocks to accommodate the greater stroke and longer rods, you have to assume that when 440-size parts are stuffed into a 400, they will require customizing. To prevent the 440 crank and rods from pushing the piston out the top of each bore, Barton uses custom JE forged slugs with raised pin locations and shallow skirts. At TDC these flat-top pistons are 0.010 inch below the deck, and at BDC their compact skirt configuration clears the crank counterweights with room to spare. Best of all, at 540 grams, the slugs are nearly half as heavy as stockers, which makes life easier for the rods and improves throttle response. Speed-Pro file-fit moly rings and standard-tension oil scrapers control oil consumption on the street.

Although bushed lifter bores enhance oil control, RBRE uses them to correct factory machining inaccuracies and to position all 16 lifters precisely over the cam lobes to equalize cam timing between cylinders.

Although bushed lifter bores enhance oil control, RBRE uses them to correct factory machining inaccuracies and to position all 16 lifters precisely over the cam lobes to equalize cam timing between cylinders.

Even though Barton rode an elephant to national prominence, he still has deep respect for wedge heads. On this motor he uses aluminum Indy 440-1 heads, reworked to boost intake flow from a decent out-of-the-box 290 cfm to 340 cfm. The stock 2.19-inch intake valve is replaced by a special RBRE On-Trac one-piece stainless valve with 2.25-inch (Hemi-size) heads; the seat, bowl, and throat areas are enlarged to match. The exhaust valve remains at 1.81 inches, and all valve seats are treated to a full-radius infinite-angle valve job. The valve stems are a svelte 11/32 inch, versus the clunky 3/8-inch stems on production Chrysler wedge heads.

The aluminum Indy 440-1 head is closely patterned after the iron '63 Stage II 426 Max Wedge casting; chamber configurations, port-opening dimensions, and chamber volumes are identical. But in the 440-1 the pushrods are angled outward to reduce their impact on the topography of the inner port walls, the spark plugs are angled toward the exhaust valves, and a thicker deck adds rigidity. Since the pushrods have been relocated, the engine needs custom Indy offset rocker arms. And the 0.700-inch-thick deck ensures excellent gasket-clamping ability when used in conjunction with an ARP head stud kit.

The Cam Motion flat-tappet camshaft has 0.638-inch lift and 283-degree duration at 0.050-inch lift. To reach the 6,900-rpm power peak without skipping a beat, RBRE uses Comp Cams #924 double-valve springs, which provide 125 pounds on the seat and a stout 315 pounds at 0.500 inch of compression. Barton connects cam to crank with an RBRE On-Trac billet-steel timing gear and chain set. The crank gear is cut with nine keyways, which allow the cam timing to be advanced or retarded in 2-, 4-, 6-, or 8-degree increments. The top gear has 10 holes that reduce weight without sacrificing strength.

Cam Motion bumpstick and lifters complement the RBRE On-Trac 3/8-inch chrome-moly pushrods and lightweight billet timing-gear set. The Mopar Performance intermediate shaft has a hardened tip to prevent shear-off with the high-volume oil pump, and pinned drive gear for greater reliability.

Cam Motion bumpstick and lifters complement the RBRE On-Trac 3/8-inch chrome-moly pushrods and lightweight billet timing-gear set. The Mopar Performance intermediate shaft has a hardened tip to prevent shear-off with the high-volume oil pump, and pinned drive gear for greater reliability.

Because the 451 is based on a low-deck 400 block that puts the heads closer together than a raised-deck motor does, the factory 413/426 Max Wedge intake manifold will not fit without major surgery. The upshot is that the Indy single-plane intake and Gary Williams 1,100-cfm annular-discharge Dominator specified by Barton make as much power, but with the civility required for the street.

Filled with premium parts, this mini-stroker ain't cheap. But as they say, in the long run it's much cheaper to build your engine once rather than twice. All the same, with the substitution of less-costly iron Indy heads and perfectly capable "medium"-core parts, a 451 with similar performance could easily be built for thousands of dollars less.