We know how it is—engines are expensive. You’ve spent a great deal of time planning, reading magazine articles, and mapping out exactly what your dream engine for your project will be. Saving your pennies goes slow with all that life nonsense like bills and mortgages or rent.

But there is good news! There is low-hanging fruit in your engine compartment that is guaranteed to work for any engine, no matter what family, how high or low performance, or even if it’s got lots of miles on it. As long as it’s got decent compression and no death rattles, it can make more power, sound better, and be a hell of a lot more fun to drive. And we’re going to prove it!

Our test car is the same ’68 Mustang used for our paint and body story in the May issue. Its un-rebuilt, original 289ci has never left the engine bay (neither has the trans nor the rest of the driveline for that matter), and has about 226K of daily driving on it. Despite that, it runs smoothly and quietly with no leaks or odd noises. We know the stock 289ci two-barrel was rated at 190 hp in 1968, but that was on the old rating system and with no accessories mounted. Who knows what a new one would have made when tested on the modern SAE scale, but we’re going to find out what this one can do 45 years later!

With over a 200K miles of daily driving on it, the little small-block looks pretty good! Our test subject is a ’68 C-code two-barrel 289, though a stock four-barrel intake and Autolite 4100 four-barrel carb was swapped on the actual “day two.” The coil is original and the wires are factory correct, but have been replaced at some point in the distant past. Original exhaust manifolds dump into a factory-style GT dual exhaust system. A compression test showed five cylinders in the 120- to 125-psi range, but three dipped into the 100- to 110-psi range. It’s old!

With over a 200K miles of daily driving on it, the little small-block looks pretty good! Our test subject is a ’68 C-code two-barrel 289, though a stock four-barrel intake and Autolite 4100 four-barrel carb was swapped on the actual “day two.” The coil is original and the wires are factory correct, but have been replaced at some point in the distant past. Original exhaust manifolds dump into a factory-style GT dual exhaust system. A compression test showed five cylinders in the 120- to 125-psi range, but three dipped into the 100- to 110-psi range. It’s old!

We’re not expecting a fire-breather or any kind of big numbers, but we are looking for real-world gains that will make the car more fun to drive while we’re working toward dropping in the engine we’d rather have. And to do that we’re going to use a realistic, budget-friendly group of “day-two” bolt-on performance parts matched to the size and operating range of our engine. For those who aren’t up on the slang, “day two” is a throwback reference to mods that would typically be made “the day after” it was brought home from the dealership.

Since our engine is bone stock, we’re going with the tried-and-true air/fuel/ignition/exhaust treatment weekend bolt-on recipe that has worked for hot rodders since the dawn of time. These are the mods that make the most sense to do together since they work as a system to increase the overall efficiency of the engine. At the end of a couple of days of wrenching, you’ll have an engine that’ll make more power and sound beefier, which will make cruising around and stabbing the throttle more fun since we all like to be heard as well as seen. And, it’ll provide oodles more eye candy when popping the hood at a show or cruise-in. There’s a lot to be said for that.

To make sure we were being as fair as possible, the Autolite was treated to a full rebuild prior to testing since a decade of being parked with fuel had left it pretty cruddy and full of varnish and residue inside.

Speaking of old fuel, after a decade of sitting it’s an absolute necessity to either swap or thoroughly clean the fuel tank to prevent contaminants from fouling things. We picked up a new tank from Mustang Country with a new pickup, filter, and rubber hose and cap connection, since it was rusted inside.

With fresh fuel in a clean tank and the Autolite 4100 tuned, we put the Mustang on the dyno at Swanson Performance in Torrance, California. Swanson specializes in late-models, but is happy to handle vintage muscle as well. Despite running like a sewing machine, the Mustang only wheezed out 119 hp at 4,100 rpm and flatlined until 4,500 where we stopped the pull. Torque peaked at 175 lb-ft at 3,000.

From Swanson’s, our Mustang went directly to Hahn Brothers Racing. After getting it on jackstands, job one was to remove the very old factory GT dual exhaust system. Old factory pipes will always have large reductions in diameter in the bends due to the way they are formed. Small reductions aren’t too bad on low performance engines, but in areas up and over the rear axles, the pipe can be reduced by .5 to .75 inch, which does make a difference.

Flowmaster makes perfect exhaust easy and affordable for most popular muscle cars with their American Thunder kits. The pipes are stainless steel for corrosion resistance and are a true 2.5-inch diameter all the way through, thanks to mandrel bends. Note that we chose the non-GT option with slight turndowns that will tuck the exits at the edge of the rear valance. The mufflers are the fabulous-sounding 40-series two-chamber.

The system assembles with slip-fit connections and heavy band clamps, or you can weld it solid. We prefer to keep the clamps since it makes disassembly of the system for service much simpler.

Log-style manifolds are a power killer on any engine, so you’ll never catch them on one of our projects! We went with Hooker Headers Comp Series ceramic-coated long tubes. They are cheaper in a painted finish, but we always opt for the ceramic coating for corrosion resistance. It’s well worth the extra investment since they can last a lifetime.

We’re not going to lie, it takes just the right combination of twisting and wiggling to get the headers installed without unbolting anything, especially when working from the floor, but it can be done. Jim Hahn has done this many times before and knows that once you get them at just the right angle, the Hooker Comp headers slide right into place and fit like perfection.

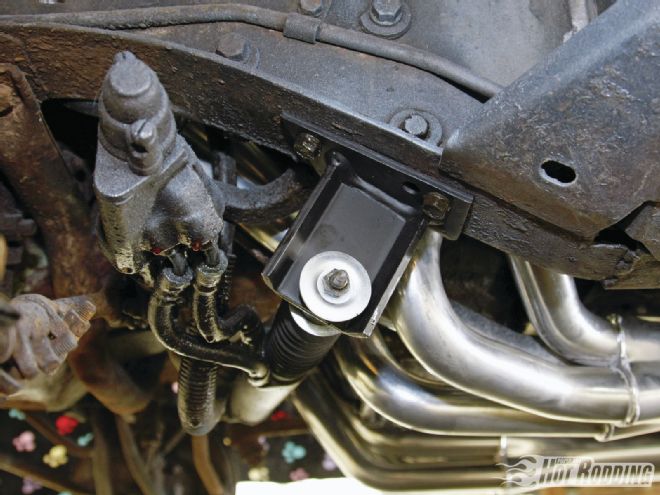

The one thing you do have to unbolt on power steering–equipped Mustangs is the power steering ram. This drop bracket from Hooker is required for clearance on the tubes. It’s an easy three-bolt operation. We picked up exhaust reducers (3 to 2.5 inches) from Team C Performance in Bellflower, California.

With the exhaust handled, Hahn dropped the Mustang back onto the ground and started on the topside mods by pulling the Autolite carb and original cast-iron four-barrel intake to get our air intake on par with the exit.

It’s called the “Performer 289,” so of course we chose it! Seriously though, Edelbrock’s #2121 low-rise, dual-plane intake is ideal for small engines operating in the idle to 5,500-rpm range like our 289, which had an original cam. And, of course, the aluminum casting takes significant weight off the top of the engine versus iron.

All the air and fuel in the world won’t do an engine any good if it can’t ignite it. To stay with our easy bolt-on theme, we left the stock distributor alone and installed one of PerTronix’s high-energy Ignitor III modules.

Speaking of ignition, the original coil was still lurking on the intake. These things can last forever, but their output is weak versus what's available in the aftermarket, and they don't fare well with multiple spark ignitions. We'll be swapping it for a canister-style Flame-Thrower III coil from PerTronix, which offers 45,000 V of power.

They may be known for their line of high-end race carbs, but Quick Fuel Technology also builds killer street carbs. Our choice for the little 289 is the smallest four-barrel in their affordable Hot Rod Series: the 580-cfm HR-580-VS. These carbs are designed for performance street use, but they still offer superior tuning with vacuum secondaries adjustable by simply turning a screw, four-corner idle, screw-in air bleeds with idle feed restrictions, dual-inlet fuel bowls with Quick Set sight windows for easy float level adjustment, and QFT’s four-door power valve with a strong diaphragm and blow-out protection.

Here’s our vintage “day-two” makeover on our 289. Atop the QFT carb is a reproduction 289 Hi-Po chrome air cleaner housing from Mustang Country with a reusable high-flow cotton element from Summit Racing. We paired that with a ’68-style chrome “Power By Ford” valve covers, also from Mustang Country. Note the stock-looking wires are actually PerTronix “stock look” performance wires that offer low resistance while keeping a vintage look. Our PerTronix canister coil is mounted with the original bracket on the stock A/C compressor bracket to keep it away from heat.

The QFT carb is shipped with a basic tune that should be very close for any mild V-8 like ours, and indeed it was. All that was needed was a little adjustment to the idle mixture by dyno maestro Joel Cady. Other than the slight adjustments to the carb, our only other changes were adjustments to the ignition timing. We ended up pulling out 4 degrees for a total of 28 degrees to get our final numbers.

After a leisurely weekend bolting on parts at Hahn Brothers Racing, we took the Mustang back to Swanson Performance to see what our parts were worth. The first thing we noticed was the throaty muscle car sound from the new Hooker and Flowmaster exhaust. The 289 sounded like so much more engine. It’ll definitely be a head turner at any cruise night.

The final SAE corrected peak numbers were 154.1 hp and 191.0 lb-ft of torque, and our engine’s rpm range was extended by 500 rpm. That’s very significant considering power being soaked up by the equally high-mileage C4 auto. It’s an educated guess, but we are pretty comfortable saying that the right choice of bolt-on power parts has our 226,000-mile 45-year-old 289 making more than its original advertised horsepower. But the real story is how much more fun it is to drive with the extra power and throaty sound!

We’d like to thank our friends at both Mustang Country in Paramount, California, and Hahn Brothers Racing in Stanton, California, who helped install and dyno test our day-two mods. At the end of the day, we spent about $1,700, which doesn't include the cosmetic mods, for an increase of 35 hp and 15 lb-ft of torque (peak-to-peak). That’s a pretty good deal for a 45-year-old engine, and should we decide to rebuild or replace the old 289, these bits can be reused for even more power!

10 Bolt-Ons To Glory

Description:

PN:

Cost:

Edelbrock Performer 289 intake

2121

$174.95

Flowmaster American Thunder exhaust

817282

$478.77

Hooker Competition headers (ceramic coat)

6901-1HKR

$385.95

Mustang Country 289 Hi-Po air cleaner

C5ZZ-9600-W

$27.95

PerTronix Ignitor III ignition module

71281

$123.95

PerTronix Chrome 45,000 V canister coil

44001

$45.95

PerTronix “stock look” plug wires

708105

$42.95

Quick Fuel Technology 580-cfm carb

HR-580-VS

$378.00

Summit Racing air cleaner element

SUM-239143

$28.95

Team C Performance header reducers

21102

$46.29

On The Dyno

RPM:

TQ before:

HP before:

TQ after:

TQ change:

HP after:

HP change:

3,000

175.7

100.3

163.4

-12.2

93.5

-6.8

3,200

174.2

106.1

169.2

-4.9

107.9

+1.8

3,400

171.9

111.3

173.5

+1.5

116.1

+4.8

3,600

167.4

114.7

189.3

+21.9

129.7

+15.0

3,800

161.6

116.9

191.0

+29.4

137.6

+20.6

4,000

156.3

116.9

189.5

+33.2

144.3

+27.4

4,100

152.5

119.1

186.5

+34.0

145.6

+26.5

4,200

148.1

118.4

186.5

+38.4

149.2

+30.7

4,400

140.0

117.3

180.4

+40.3

151.1

+33.8

4,500

136.9

117.3

175.7

+38.8

150.6

+33.3

4,600

N/A

N/A

175.1

N/A

154.1

N/A

4,800

N/A

N/A

167.0

N/A

152.6

N/A

4,900

N/A

N/A

155.8

N/A

145.4

N/A