In the early days of hot rodding, with the majority of hot rods being Fords, it stands to reason the ’30s and ’40s Ford “banjo” rearend dominated the scene. It’s still popular today with builders of traditional rods, even with the later 8- and 9-inch Ford axles being the mainstay of the street rod market.

However, those old banjo rears had an Achilles’ heel, and a pretty nasty one at that. Should you be unfortunate enough to break an axle in one of these early Ford rearends, you’d likely lose the remaining part of that snapped axle, the wheel, and the brake drum! Not a pleasant experience, especially at speed. Even early hot rodders tried to come up with ways to keep the drum in place should they break a shaft. Today, Vern Tardel and Speedway Motors sell a simple drum retainer that bolts in place.

1 There aren’t many parts in a ’40 Ford banjo rearend when it is taken apart.

1 There aren’t many parts in a ’40 Ford banjo rearend when it is taken apart.

When it came to the ’40 Ford rearend in his latest project, Bo Bertilsson wanted to go a few steps farther than just a drum retainer though, wanting to thoroughly modernize the old rearend but maintain its period appearance. A call was put in to Hot Rod Works (HRW) in Indiana for one of their modern axle conversion systems.

2 Here are a few old stock axles that show some problems from worn bearing surfaces at the top, to twisted and broken keyways. It’s easy to see that the tapered shafts are a weak point for the banjo rearend.

2 Here are a few old stock axles that show some problems from worn bearing surfaces at the top, to twisted and broken keyways. It’s easy to see that the tapered shafts are a weak point for the banjo rearend.

Most builders who use the old Ford rearend do so for a traditional appearance, either with or without a quick-change conversion. Adding a quick-change still doesn’t resolve the safety issue, but with the HRW axle kit that’s taken care of. You can now modify the old rearend with new 9-inch Ford axles and the complete rearend will still look like an original banjo axle.

However, there a few choices to make. Do you want to use the original rearend housings and centersection, or a completely new rearend that looks like the Ford? Quick-change or original centersection? What size driveshaft bearings and brakes do you want?

In our case we wanted to make the rearend safer and stronger, but keep the original look. How often do you change the gears in a quick-change anyway? Most rodders set it up once and never change them. Many do it for the look of the polished centersection. We went with the stock-type centersection. Next choice was the brakes, and we plan to use stock ’40 Ford-type brakes, which also include the possibility of ’39 Lincoln-style drums, as they’re a bit more effective. Those can be bought new today too. The choice with the original ’40 Ford bolt pattern for the backing plates makes things a little easier. That way you can use the original Ford housings, though they have to be modified for the later 9-inch-style shafts to fit by machining the bearing housings off the ends.

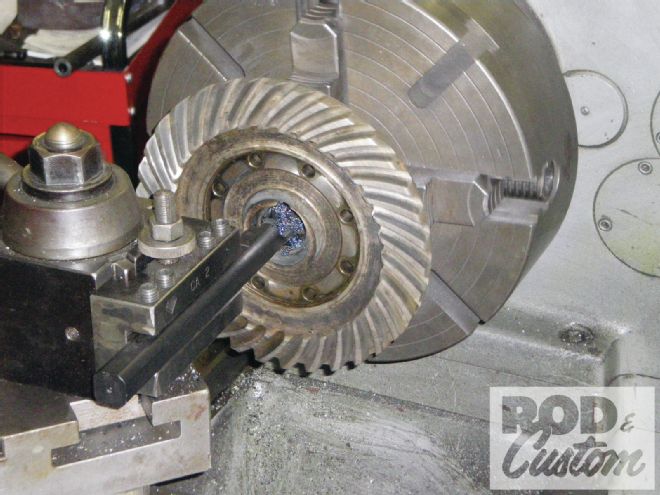

3 The hardened ring gear was machined to allow the new, larger axle gears to fit.

3 The hardened ring gear was machined to allow the new, larger axle gears to fit.

We sent the two housings to HRW in Indiana to have the work done, although we could have opted for later Ford drums and bolt pattern, which require another bearing size. HRW has so many old Ford rearends in stock that they can sell you all the parts or put a complete rearend together for you. Our ’40 rearend had the housings and ring gear machined, to enable the new axle shafts go through the centersection. Machining the ring gear is not that easy because it is hardened, so it was smart to let the experts at HRW take care of that. The kit includes new axles with big bearings and wheel studs, axle seals, bearing adapters, hardware, and axle gears. The conversion requires the use of 11-tooth spider gears.

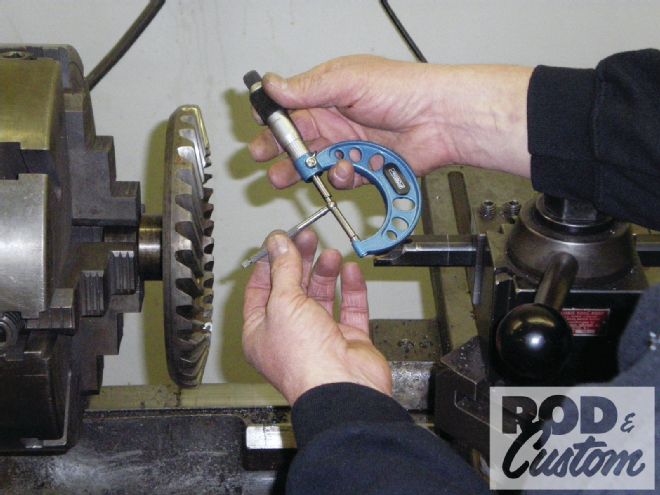

4 The tolerances are checked during the machining operation.

4 The tolerances are checked during the machining operation.

An early Ford rearend is simple, but it takes some extra time to set it up and get the gear mesh pattern just right. This is achieved by using gaskets of differing thicknesses for the housings. With pattern paint on both pinion and ring gear, the centersection is put together, then the housings are bolted in place, and the axles installed. The axle is turned some, then taken apart again to check the pattern. If it is close, the process is repeated with thicker gaskets until the best possible pattern is achieved. If it is way off, the pinion has to be taken out and shimmed. That might happen with new rearend gears sometimes. Many doing the conversion to 9-inch axles also convert to open drive with another HRW kit, especially if a transmission other than a ’39 Ford type will be used. Ford used the same rearends in an open-drive version on some of the pickups (early F-1), but those rearends aren’t that easy to find today. The HRW kit is made for either 6- or 10-spline pinions, depending on which type a customer has.

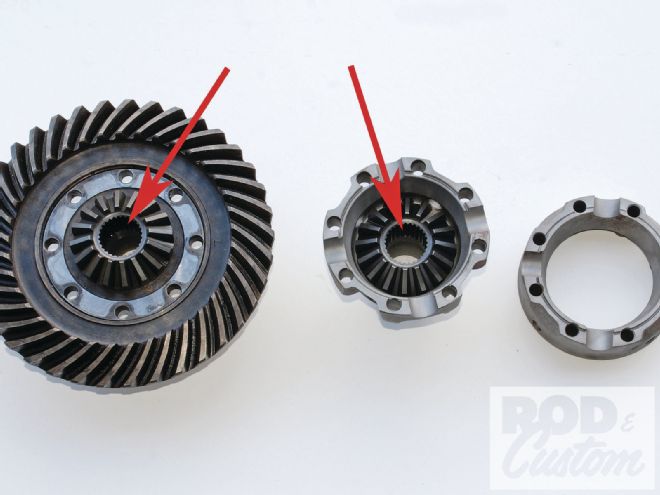

5 When the machined parts came back from Hot Rod Works, the differential housing and the ring gear had been machined (arrow) for the new larger axle gears.

5 When the machined parts came back from Hot Rod Works, the differential housing and the ring gear had been machined (arrow) for the new larger axle gears.

With the rearend completed and the new 9-inch axles in place, we have a more modern, safer axle, and even with the stock gears, it can take much more punishment than the stock axle ever could!

6 Here the axle gears are in place. The splined inner ends of the new axles will locate inside them.

6 Here the axle gears are in place. The splined inner ends of the new axles will locate inside them.