When it comes to applying the latest technology to street rods some of us are more enthusiastic than others. If nuclear powerplants suddenly became available you can be sure Brennan would shoehorn a reactor under the hood of his highboy. Then there are those of us who are skeptics. Not to name names (editor’s note: this from a man whose calendar ended in 1967!), we all know guys who held back on the newest whatchamacallit until it was proven, who chose to stick with eight-tracks because cassettes would never catch on, and who believed points were superior to electronic ignition because you could always adjust those simple breakers out in the middle of nowhere, but if a module died you’d be stuck (editor’s note: Ron is unaware that you can purchase extra modules to place under the seat—where he keeps his Cheetos!).

Typical of today’s crop of electronically controlled transmissions is the GM 4L60E. Note the plug (arrow) where the wiring harness from the computer plugs in.

Typical of today’s crop of electronically controlled transmissions is the GM 4L60E. Note the plug (arrow) where the wiring harness from the computer plugs in.

The truth is today most of us have been listening to CDs for some time, haven’t changed a set of points in years, and have come to believe computers and hot rods are no longer mutually exclusive. Little black boxes of some sort are in and run almost everything in a contemporary automobile and there’s no arguing that performance and longevity have improved as a result and more of that technology is finding its way into our hobby on a daily basis. One of the most recent advancements to impact our world are the variety of computer-controlled automatic transmissions that are now available.

Ford’s lineup of electronic overdrive automatics includes the bulletproof E4OD.

Ford’s lineup of electronic overdrive automatics includes the bulletproof E4OD.

With the introduction of automatic overdrive transmissions, rodders found they could have the best of both worlds: a transmission with a low First gear for off-the-line acceleration, and an overdrive gear of more economical highway cruising. When first introduced, these overdrive transmissions used controls that were similar to their three-speed predecessors, mechanical throttle valve linkages, vacuum switches, internal governors, and so on. But it didn’t take long for the OEMs to figure out a better way was to use a computer that allowed the engine and transmission management systems to communicate with each other. Unfortunately, for our purposes that meant that installing computer-controlled transmissions in street rods was going to require stand-alone electronics.

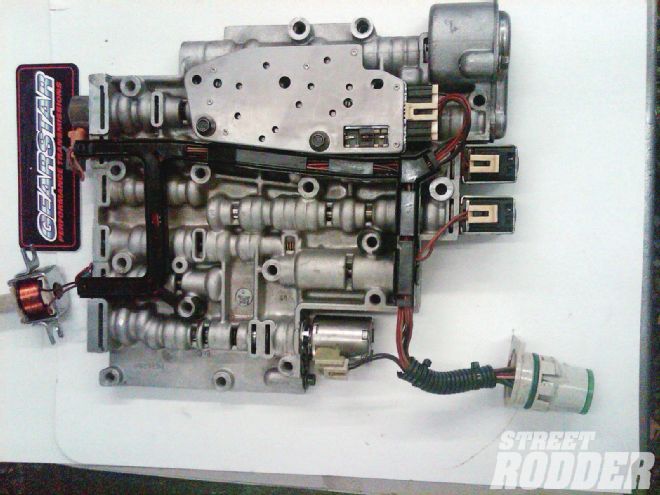

Valve bodies of computer-controlled transmissions use electric solenoids to move the various shift valves. The TPS and TOSS take the place of the often-troublesome throttle valve cable.

Valve bodies of computer-controlled transmissions use electric solenoids to move the various shift valves. The TPS and TOSS take the place of the often-troublesome throttle valve cable.

Much like the early retrofit fuel injection systems, most of the first aftermarket transmission controllers had to be programmed with a laptop and for many rodders that was enough to make stay away; after all we’re talking about some guys who still have clocks blinking on their VCRs. Fortunately there are now controllers that are plug-and-play, like the Compushift II from HGM Automotive Electronics. The guys behind HGM today are Mike Hoy, who has been in the transmission business since the ’60s and Guy Cardwell, an electrical engineer, who Hoy describes as the sharpest guy he knows in electronics.

The control unit is truly plug-and-play. On one side are ports for the engine and power harnesses.

The control unit is truly plug-and-play. On one side are ports for the engine and power harnesses.

As Hoy explains it, without a controller these modern transmissions are literally “brain dead.” However, with a properly designed management system they are tunable to provide high performance for a variety of applications. Computers offer total control of shift points, shift quality, and converter lockup. And from our standpoint the best thing about them is they totally eliminate finicky and problematic throttle cable adjustments. In simple terms, these computers control the transmission based on the input they’re provided from a variety of sensors, such as:

HGM’s Compushift transmission controller is small and compact but houses a huge amount of little electric brain cells.

HGM’s Compushift transmission controller is small and compact but houses a huge amount of little electric brain cells.

Transmission Output Shaft Speed (TOSS) Sensor: As the name implies, it measures the speed of the driveshaft. This sensor can also supply a signal for an electronic speedometer. However the TOSS signal for the computer should never be connected to the speedometer; there is a wire called “reproduced TOSS” for that purpose.

On the other side are ports for the transmission harness (Trans 1) and optional line-pressure sensor (Trans 2) and the available display unit.

On the other side are ports for the transmission harness (Trans 1) and optional line-pressure sensor (Trans 2) and the available display unit.

Throttle Position Sensor (TPS): Again, as the name implies, this sensor detects the position or opening of the throttle. In the case of engines with electronic fuel injection the existing TPS can be used. For carbureted applications HGM offers an add-on TPS with a bracket to mount it and a link to connect it.

Manual Lever Position Sensor (MLPS): Ford uses this sensor, or a variation of it, to tell the computer what gear the transmission is in. On GM transmissions this function is done internally. While on the subject of Ford overdrives, they do have some unique features that we should point out. Like most transmissions Park, Reverse, and Neutral are standard shifter positions, but unlike many other four-speed overdrive automatics there are only three other shifter positions—D, which allows the transmission to shift through all four gears; 2, which locks the transmission in Second gear only (the vehicle starts in Second and stays there); and 1, which locks the transmission in First and keeps it there. What’s missing is a Third gear position, but while it may not be on the gearshift indicator it is available with the push of a button. The Compushift II comes with what is called a “cancel switch,” which prevents the transmission from shifting into Fourth (however the converter will still lock).

For carbureted applications HGM can supply the AccuLink TPS control kit.

For carbureted applications HGM can supply the AccuLink TPS control kit.

Installing the Compushift II controller is simple enough. It should be mounted away from any sources of extreme heat, and that includes the heater outlet. All the wires are clearly labeled; all the plugs are dedicated and will only fit in the proper place, but do yourself a favor and read the instruction before you begin installation. But if you have any questions the helpful tech guys are just a phone call away.

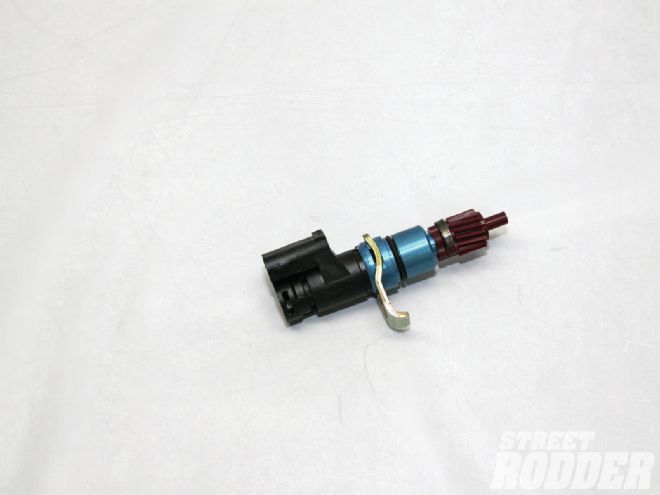

The TOSS plugs into the opening in the transmission that housed the speedometer sender and provides information to the control unit. A duplicated TOSS signal is available to drive electronic speedometers.

The TOSS plugs into the opening in the transmission that housed the speedometer sender and provides information to the control unit. A duplicated TOSS signal is available to drive electronic speedometers.

While the HGM Compushift II computer is an extremely smart device, it’s something simple that will dumb it down—a bad ground. After everything in your street rod is painted, plated, and powdercoated, it can be tough to find a good spot to ground electrical components, but a good ground is absolutely essential to the proper operation of the HGM system (as well as every other electrical device). That’s why HGM recommends grounding their system directly to the block (but the connection point still needs to be clean, bare metal).

Once installed no laptop is needed to program the Compushift II. The system is delivered with factory-set programming for a wide variety of transmission and engine combination, however a setup screen can be used to input information, such as number of engine cylinders, gear ratio, tire diameter, and more, if necessary. In addition a PC can be connected via the USB port for system software updates and advanced tuning if desired.

There’s no question that a computer offers the most precise control of today’s incredible overdrive automatics while allowing alterations for special circumstances. The Compushift II can be programmed to deliver neck-jerking shifts under full throttle, yet provide smooth driveability during light throttle and cruising—that’s real automagic.

This is the optional Fourth gear lockout button used on Ford overdrives; it connects to the HGM harness.

This is the optional Fourth gear lockout button used on Ford overdrives; it connects to the HGM harness.

Oh, by the way, anyone want to buy a box of eight-track tapes?

Basic Transmission Operation

To appreciate all the Compushift II can do, HGM believes it’s helpful to understand how an automatic transmission works.

The major components in your transmission include:

Torque Converter: A special fluid coupling that makes the connection between your transmission and engine. It drives the gears in the transmission, which in turn, moves the vehicle. This device has a special clutch called the “torque converter clutch” that directly connects the engine to the transmission in the same way a manual transmission clutch operates. This is usually done to improve fuel economy.

The Compushift II display is used to program the TPS and other functions. It can also provide a host of information about the transmission as you are driving.

The Compushift II display is used to program the TPS and other functions. It can also provide a host of information about the transmission as you are driving.

Hydraulic Pump: Pumps oil in the transmission to provide lubrication and pressure to actuate clutches, bands, and other components.

Control Solenoids: These electrically controlled valves turn oil pressure on and off in the valve body and adjust hydraulic pressure.

Valve Body: The valve body, in turn, routes oil pressure to the clutches and bands.

Gear sets: These are a combination of gears that mesh to provide a specific gear ratio. Any planetary gear set has three main components: sun gear, planet gears and the planet gears’ carrier, and ring gear.

Clutches and Bands: Clutches and bands alternatively connect and disconnect different gears in the transmission. The correct sequencing of band and clutch activation is what shifts the transmission.

A: PWM stands for “pulse width modulation.” In transmission control applications, PWM is a way of controlling a solenoid so that it applies varying amounts of hydraulic pressure according to computer control. PWM torque converter clutch systems use apply and release the clutch gradually to improve shift feel. Unfortunately, many of the PWM controlled systems cause the clutch to slip, and over time, eventually fail. Over time, manufacturers have introduced and then later removed this gradual apply/gradual release feature. Some types of transmissions have been built with both PWM and non-PWM versions of the converter clutch. For those transmissions, Compushift II has a setup menu selection that lets you choose PWM or non-PWM. Whether PWM or not, the Compushift II always does a quick apply and release of the torque converter clutch. We feel that it is more important, especially in high-horsepower applications, to preserve the life of the clutch rather than improve shift feel.

Line Pressure: The amount of hydraulic pressure applied to the clutches determines how the transmission shifts. Under low pressure, the clutches engage slowly and softly, making a gentler shift. Under high pressure, the clutches engage rapidly and the shift is firm.

FAQs

Q: Do I have to purchase the display programmer in order to correctly install Compushift II?

A: No. Every Compushift II comes with the digital display. Throttle calibration and shift point/shift pressure adjustment can be done without the display. The display does offer the greatest flexibility in setup, though. It can also serve as a “digital dashboard,” providing you with running information about vehicle and transmission performance.

Q: Do I need a laptop computer to program the system?

A: No. All adjustments and programming to Compushift II can be done with the handheld display/programmer.

Q: Does the torque converter clutch (TCC) unlock during gear changes?

A: The torque converter clutch always unlocks during downshifts, and sometimes during upshifts, depending on the vehicle speed and throttle position. It is safe to upshift under light load while the TCC is locked, and most OEM systems do so.

Q: How do I run an electronic speedometer with Compushift II?

A: Compushift II provides an output signal for driving speedometers. This signal is called reproduced TOSS. This signal replicates the signal coming from the Transmission Output Shaft Speed (TOSS) sensor. A device called the Cable-X can drive mechanical speedometers if necessary. Built by Abbott Enterprises, the small Cable-X box motor rotates a speedometer cable at a rate proportional to an electronic speed input, and is calibrated to match your speedometer using internal switches. HGM is an authorized Cable-X reseller.

Q: How do I use an existing throttle position sensor?

A: A throttle position sensor usually has three wires: +5V power, ground, and signal. The power and ground wires supply a reference voltage to either side of a variable resistor. As the shaft rotates, the signal wire has a voltage that varies between +5 V and ground. In order to connect Compushift II to an existing TPS, you only need to connect two wires, the ground wire and the signal wire. These can be piggybacked on top of the existing wiring using an in line wiretap, but they should be done as close as possible to the sensor. The +5V wire coming from the Compushift II should be left disconnected, but insulated to prevent a short circuit.

Q: I don’t understand the function of the “always upshift at” setting. What exactly does it do?

A: The “always upshift at” places an absolute engine rpm limit on each gear. The controller will always upshift when this engine rpm is reached. The controller measures engine speed from the tachometer input, if connected, or calculates engine speed based on driveshaft speed and gear ratio. The tachometer is the more accurate measurement because all torque converters slip. As the “shift speed” adjustment is increased, the transmission shifts at greater speeds for a given throttle position. The “always upshift at” provides a cap for this adjustment. This allows you to have the transmission shift at high rpm with light throttle, but still not exceed the engine’s rpm limit at full throttle.

Q: What is the difference between PWM and non-PWM torque converter clutches?