With a couple of adapter components, it's very easy to swap a Gen I manual or automatic behind your Gen III/IV engine.

With a couple of adapter components, it's very easy to swap a Gen I manual or automatic behind your Gen III/IV engine.

Engine and transmission swapping is the heart of car crafting. The GM Gen III/IV (4.8L through 6.2L engines from 1998 to present) engine swap is quickly becoming the new classic with GM musclecar movers and shakers. Up until now, a Gen III/IV engine also demanded using a late-model transmission, either a Gen III/IV-dedicated 4L60E automatic or a six-speed manual. These trans choices not only limit creativity but also tend to be more expensive. The latest move is using older transmissions, such as Gen I four- and five-speed manual gearboxes along with the classic TH350/TH400 three-speed autos and the 700-R4 and 200-4R four-speed automatic overdrives. All these transmissions can be adapted to Gen III/IV engines if you know the tricks, and that's what this story will detail. Car Craft has done all the research so all you have to do is follow the outline and save yourself money, time, and effort.

We'll break this story into sections for manual transmissions and automatics. The automatic side is pretty easy, so we'll save that for last. The manual trans info isn't difficult, but there are a few essential details that make the swap a bolt-in, so we'll start there.

Note the crankshaft flange extends past the bellhousing flange by 0.400 inch on the Gen I small-block (left), while the Gen III/IV crank flange is essentially even with the bellhousing flange (right).

Note the crankshaft flange extends past the bellhousing flange by 0.400 inch on the Gen I small-block (left), while the Gen III/IV crank flange is essentially even with the bellhousing flange (right).

Manual Trans Swaps

When GM decided to build the new Gen III small-block that would become the LS1, GM's engineers carried over a couple of important design characteristics that make it easy to retrofit newer engines into older cars. It's doubtful that GM considered car crafters' requirements when it designed these new Gen III/IV engines, but regardless of the company's agenda, it did us a couple of big favors. The first gift is that the Gen III/IV bellhousing pattern is almost identical to the original small-block Chevy. Five of the six bellhousing bolts are in exactly the same location, as are the size and location of the two dowel pins. This one fact allows us to make everything else work. The Gen III/IV bolt pattern is not symmetrical, which is odd, and the top center bolt is employed while the upper passenger side bolt is not. But if using five of the six bolts works for you, then everything else is easy. As you will see, there are plenty of options that allow you to use all six bolts.

The McLeod adapter flywheel (left) offsets the distance to the flywheel friction surface rearward (toward the transmission) an additional 0.400 inch to make up for the shorter crank flange position on Gen III/IV engines. Note the Gen III/IV flywheel bolt pattern is smaller than the Gen I bolt pattern (right). The McLeod flywheel is relieved on the backside to maintain its 35-pound weight.

The McLeod adapter flywheel (left) offsets the distance to the flywheel friction surface rearward (toward the transmission) an additional 0.400 inch to make up for the shorter crank flange position on Gen III/IV engines. Note the Gen III/IV flywheel bolt pattern is smaller than the Gen I bolt pattern (right). The McLeod flywheel is relieved on the backside to maintain its 35-pound weight.

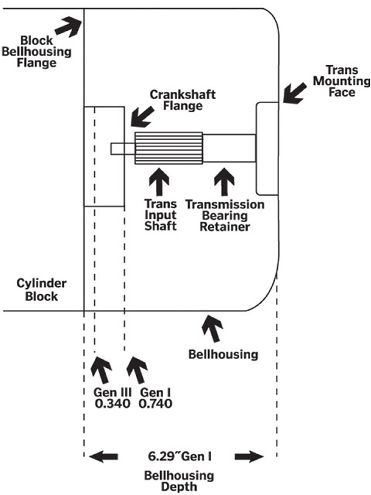

Unfortunately, GM engineers also added a few hurdles just to make this swap game more challenging. First and foremost, the crankshaft flange on a Gen III/IV engine is essentially even with the bellhousing flange on the block. On the original small-block and big-block Chevy engines, the crankshaft flange extends 0.400 inch farther rearward (aft, if you're nautically inclined) of the bellhousing flange. This is the critical differential measurement that defines all the other modifications we have to make to adapt earlier transmissions.

Another important piece to this swap puzzle is that all Gen III/IV engines use a distinct crankshaft mounting flange. This means now we have three separate crank flanges: the Gen I small-block with a two-piece rear main seal, the Gen I with a one-piece rear main seal, and now the Gen III/IV engines with their one-piece rear main seal. While this should come as no surprise, the Gen III/IV engines are now completely metric, demanding all new fasteners. Obviously, this means Gen I flywheels and flexplates will not interchange with a Gen IIII/IV engine. One other important tech tidbit is that all Gen III/IV engines use a 168-tooth flywheel or flexplate.

This simple illustration shows the differences in position of the Gen I crankshaft flange versus the Gen III/IV flange in relation to the bellhousing mounting surface.

This simple illustration shows the differences in position of the Gen I crankshaft flange versus the Gen III/IV flange in relation to the bellhousing mounting surface.

Given all this, the quickest way to adapt an early four- or five-speed manual trans to a Gen III/IV engine is to make up this 0.400-inch difference in crankshaft flange position. McLeod Clutches, which was recently purchased by B&M, has solved this problem with a 168-tooth flywheel that will bolt up to the Gen III/IV crankshaft and extends the flywheel face by exactly 0.400 inch. This places the clutch and pressure plate surface at the correct height so you can either bolt on a new clutch and pressure plate assembly or use a Gen I clutch and pressure plate assembly you already have. This custom McLeod flywheel is drilled to accept the traditional 11-inch Borg & Beck/diaphragm-style pressure plate bolt pattern using original 3/8-inch shouldered pressure plate bolts.

The Keisler aluminum bellhousing employs both the Gen I and III/IV bolt patterns so it can be used on either engine. Of course, an 11-inch Gen I small- or big-block bellhousing can also be used as long as you're willing to sacrifice one mounting bolt hole. Standard small-block 101/2-inch (153-tooth) bellhousings will bolt up to a Gen III/IV engine but won't clear the 168-tooth flywheel.

The Keisler aluminum bellhousing employs both the Gen I and III/IV bolt patterns so it can be used on either engine. Of course, an 11-inch Gen I small- or big-block bellhousing can also be used as long as you're willing to sacrifice one mounting bolt hole. Standard small-block 101/2-inch (153-tooth) bellhousings will bolt up to a Gen III/IV engine but won't clear the 168-tooth flywheel.

Before we bolt on the bellhousing, there is one other crucial step that must not be overlooked. It should be common knowledge that a pilot bushing positioned in the end of the crankshaft supports the transmission input shaft, preventing deflection when the clutch is disengaged. In our trans-swapping effort, remember that while the depth of our bellhousing is the same as with a Gen I engine, the crankshaft flange is 0.400 inch farther forward. Since the input shaft length on our traditional four-speed or five-speed transmission has not changed, we also have to move the position of the pilot bushing rearward to compensate for the discrepancy. McLeod has again come to the rescue with an adapter pilot bushing that sits in the larger recess in the crank and therefore supports the input shaft in the proper location. If you don't pay attention and incorrectly place a stock pilot bushing in the original spot in the Gen III/IV crank, the transmission input shaft will not be supported and the input shaft bearing will fail almost immediately. We also discovered that GM makes a special LS2/LS7 pilot bearing that will adequately support the shorter input shaft.

This brings us to the bellhousing. Because all Gen III/IV engines use a 168-tooth flywheel and flexplate diameter, not all small-block Chevy bellhousings will work when it comes to bolting on an older four- or five-speed manual trans. This larger flywheel requires the rare 11-inch-style bellhousing. To use the larger flywheel, you'll either have to dig up a used 11-inch bellhousing or scattershield, or you can order a brand-new aluminum factory-style bellhousing from Keisler that will not only accommodate the larger flywheel but is drilled for the Gen I and Gen III/IV bolt patterns. One thing we discovered is the Keisler bellhousing is cast 0.200 inch deeper than a standard GM bellhousing. The standard GM bellhousing depth is 6.290 inches from the engine bellhousing face to the transmission mounting face, while the Keisler specs out at 6.490 inches. This affects input shaft placement relative to the crank as well as the position of the clutch disc. Another option is using a scattershield from Quick Times that also combines the Gen III/IV bolt pattern with the standard Gen I-style bell-housing depth.

Even using the custom offset McLeod flywheel, this custom McLeod pilot bushing adapter is necessary to properly support the input shaft.

Even using the custom offset McLeod flywheel, this custom McLeod pilot bushing adapter is necessary to properly support the input shaft.

We're not quite there yet. We prefer to keep everything simple by retaining the original mechanical clutch linkage, avoiding the added expense of a hydraulic system. The problem is Gen III/IV engines do not have a provision in the block for the engine-mounted ball stud pivot for the clutch linkage Z-bar. While discussing this with Scoggin-Dickey Parts Center's (SDPC) Nickey Fowler, he mentioned SDPC makes an adapter bracket originally designed for the Gen V/VI factory Rat blocks that also did not come with this ball stud provision. This SDPC bracket bolts to the lower two bellhousing bolts on the driver side and places the ball stud in exactly the right position for the Z-bar. This is the best scenario for adapting a Gen I-style manual trans behind a Gen III/IV engine that is easy and not overly expensive.

We re-created the 6.29-inch distance between the transmission face and the bellhousing flange to illustrate where the input shaft sits in relation to the Gen III/IV crankshaft. Note the input shaft falls short of the stock pilot bushing location.

We re-created the 6.29-inch distance between the transmission face and the bellhousing flange to illustrate where the input shaft sits in relation to the Gen III/IV crankshaft. Note the input shaft falls short of the stock pilot bushing location.

Not-So Shortcuts

Car crafters are the masters of adapting parts to achieve a solution. As you might have guessed, there are other ways to arrive at adapting a Gen I four- or five-speed manual trans behind a Gen III/IV engine. One idea involves using a Gen III/IV flywheel. Bolting on a stock metric Gen III/IV flywheel is easy, but again, it will also be short by 0.400 inch. According to McLeod, a production Gen III/IV pressure plate and clutch assembly stands roughly 1 inch taller than a Gen I diaphragm pressure plate. Even accounting for the shorter Gen III/IV flywheel, this places the metric pressure plate fingers roughly 0.600 inch taller than a Gen I system. Since this does not allow sufficient room for the release arm bearing, it won't work.

However, if you have a good Gen III/IV flywheel, you could have a machine shop drill it for the standard diaphragm counterbored bolt pattern using the correct 3/8-inch shouldered bolts. As you will discover, the stock metric pressure plate bolt pattern is the same as the Gen I 11-inch diaphragm pressure plate pattern. Do not use the Gen III metric bolt holes to attach an old-style pressure plate because these bolt holes are not counterbored and will not properly locate the pressure plate. All Gen III/IV metric pressure plates use a pair of small drive pins as locators. Since this conversion will use the 3/8x16 shouldered bolts, machining a separate bolt pattern and counterboring the bolt holes for the shouldered bolts will be necessary.

This is McLeod's street diaphragm pressure plate and clutch assembly designed for a late Muncie/Super T10 26-spline input shaft. The McLeod flywheel is drilled for two pressure plate bolt patterns. One pattern is for an 11-inch clutch assembly using shouldered 3/8x16 coarse thread bolts, while the second is for a metric 11-inch pressure plate using 10mm metric bolts. Be sure to match the older-style pressure plate with the traditional 3/8-inch bolt pattern.

This is McLeod's street diaphragm pressure plate and clutch assembly designed for a late Muncie/Super T10 26-spline input shaft. The McLeod flywheel is drilled for two pressure plate bolt patterns. One pattern is for an 11-inch clutch assembly using shouldered 3/8x16 coarse thread bolts, while the second is for a metric 11-inch pressure plate using 10mm metric bolts. Be sure to match the older-style pressure plate with the traditional 3/8-inch bolt pattern.

This combination of a short flywheel and standard-height pressure plate package will also place the pressure plate fingers roughly 0.400 inch farther forward, which screws up the linkage geometry. There are actually two quick fixes for this situation. McLeod makes an adjustable-height throwout bearing that is taller and will compensate for the shorter flywheel. It runs a little less than $95, compared with the standard bearing of around $65. The second route is a taller GM release arm ball stud or an adjustable ball stud from McLeod that allows you to set the proper height of the release arm and optimize the release arm geometry. Ideally, you want to position the outboard portion of the release arm (the part actuated by the clutch linkage) angled slightly toward the front of the car. This position minimizes linkage movement while maximizing throwout bearing travel. The best choice would probably be the taller GM ball stud at less than $15.

Unfortunately, there's a downside to this approach. Because the Gen III/IV flywheel is 0.400 inch short in relation to the transmission input shaft, the clutch disc hub will ride on the input shaft very close to the end of the splines. While the input shaft is supported, this unusual location may create an additional load that could adversely affect the longevity of the pilot bushing and/or the transmission input shaft bearing. This condition is made even worse when using the Keisler bellhousing with its 0.200-inch increased depth. Buying a new Gen III/IV flywheel and then investing additional money in machine work may end up costing more than the McLeod flywheel. Given those realities, there are several reasons why the McLeod custom flywheel is the best overall choice.

Note the 3/8-inch bolt hole is counterbored to use shouldered bolts like the one in the photo. The bolt shoulder acts as a locator to accurately position the pressure plate on the flywheel. Never use fully threaded bolts to attach the pressure plate on traditional clutch applications. The metric bolt pattern uses locating pins, therefore the bolt holes in the flywheel are fully threaded.

Note the 3/8-inch bolt hole is counterbored to use shouldered bolts like the one in the photo. The bolt shoulder acts as a locator to accurately position the pressure plate on the flywheel. Never use fully threaded bolts to attach the pressure plate on traditional clutch applications. The metric bolt pattern uses locating pins, therefore the bolt holes in the flywheel are fully threaded.

Gen I Automatics Behind Gen III/IV Engines

The same mismatch between the 0.400-inch-shorter crank flange position relative to the bellhousing is what makes matching up a typical TH350/TH400/200-4R or early 700-R4 to a Gen III/IV engine a bit different. The beauty of this swap is most of the mismatch situations can be solved with the use of a simple steel adapter. GM actually faced an identical situation when bolting the 4L80E automatics behind 5.3L and 6.0L engines in larger trucks. The 4L80E automatic is basically a Gen I-style automatic, which required an adapter. To compensate, GM created a simple steel spacer that bolts on the Gen III/IV crank flange and combines with a flat flexplate. All this information is published in the GM Performance Parts LS1 engine swapping performance pamphlet. The adapter and flat flexplate, along with longer metric bolts, are intended to be used together and will allow you to bolt any Powerglide, TH350, TH400, 700-R4, or 200-4R automatic to a Gen III/IV version engine. The part numbers for these pieces can be found in the parts list at the end of this story.

Here is a look at our 5.3L engine with the custom McLeod flywheel, clutch, and pressure plate assembly enclosed in a Keisler bellhousing that mounts a Keisler-modified Tremec TKO-600 five-speed trans, which will eventually find its way into our red '67 RS Camaro.

Here is a look at our 5.3L engine with the custom McLeod flywheel, clutch, and pressure plate assembly enclosed in a Keisler bellhousing that mounts a Keisler-modified Tremec TKO-600 five-speed trans, which will eventually find its way into our red '67 RS Camaro.

Unfortunately, there are also a few minor details that need to be addressed. For example, the flat flexplate used with the spacer is designed for a 300mm (11.8-inch) bolt pattern, while most Gen I transmission torque converters use an 11.7-inch bolt pattern. The difference between these two bolt patterns ends up being roughly around 1/8 inch. As you can see in the photo, the 300mm bolt pattern holes can be carefully elongated with a file or die grinder to accommodate the smaller Gen I converter bolt pattern.

We dug a little deeper and discovered TCI makes a similar package that offers an SFI-approved performance flexplate and includes the adapter and bolts, all for an excellent price through SDPC. This flexplate bolts up to the Gen III/IV crankshaft and also features a dual converter bolt pattern that will accommodate both the early and metric torque converter bolt patterns, so no modifications are necessary. Just bolt it up and go. It doesn't get any easier than that.

If you intend to use a steel scattershield with a block plate, be aware that the Gen III/IV oil pan extends slightly rearward of the bellhousing flange. This necessitates cutting a clearance slot in the block plate as shown. If this relief is not machined into the block plate, the bellhousing/block plate assembly will not bolt up flush to the engine, causing all kinds of problems.

TORQUE SPECS TORQUE SPEC FASTENER (ft-lb, unless specified) Flywheel bolts 15 (1st pass)

If you intend to use a steel scattershield with a block plate, be aware that the Gen III/IV oil pan extends slightly rearward of the bellhousing flange. This necessitates cutting a clearance slot in the block plate as shown. If this relief is not machined into the block plate, the bellhousing/block plate assembly will not bolt up flush to the engine, causing all kinds of problems.

TORQUE SPECS TORQUE SPEC FASTENER (ft-lb, unless specified) Flywheel bolts 15 (1st pass)Breaking news!!! Roswell UFO incident turns out to be a pressure plate.