Randy Lawrence gets ready to install a Detroit Truetrac in our '32 sedan. This unit came assembled from Currie Enterprises and features 3.70:1 gears.

Randy Lawrence gets ready to install a Detroit Truetrac in our '32 sedan. This unit came assembled from Currie Enterprises and features 3.70:1 gears.

It's often said that it's never too late to learn, and that's great-but then youthful curiosity is a wonderful thing too. As an example, how many budding street rodders discovered early on that it was possible to make just one rear tire of just about any car go up in smoke every time you went around a corner? If that sounds like a vaguely familiar activity from your formative years, congratulations are in order; you learned early on the basic weakness of a differential.

While standard differentials (or open, as they're often referred to) have some shortcomings, the fact is they are a necessary component, and in most cases their performance is perfectly acceptable. In fact, driving a car on the street without a differential would be difficult at best. The reason for this is simple enough: Imagine watching from directly above as your street rod goes around in a circle. The outside wheels travel in a larger circle than those on the inside, and as a result, they have to turn faster. The front wheels aren't connected, so they turn independently, but in the rear it's the differential axle that allows this to happen.

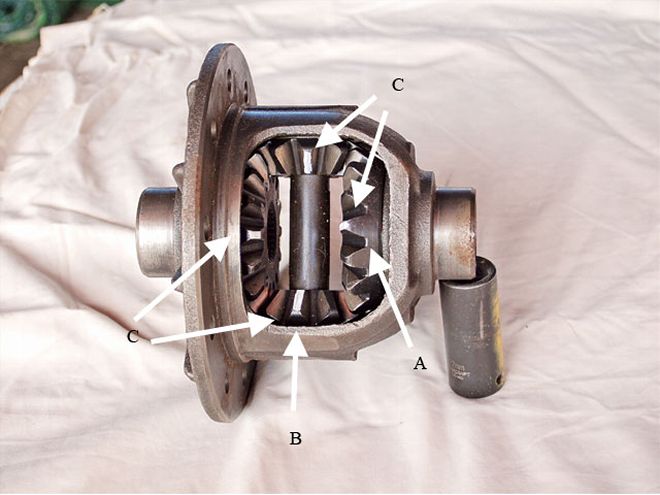

This is a standard open differential. Arrows A point to the side gears, arrows B point to the spider gears. When going straight, the spider gears don't spin (note the alignment marks arrows C).

This is a standard open differential. Arrows A point to the side gears, arrows B point to the spider gears. When going straight, the spider gears don't spin (note the alignment marks arrows C).

Although the differential performs a necessary function, there is one major drawback. In normal operation, an open differential will equalize the power delivered through both wheels, but if one tire loses traction, the differential will transfer all the power to that wheel. Remember that one smoking tire from your past?

While a differential is obviously a necessity in a street-driven car, in a performance environment it can be a nuisance if all the power makes one tire go up in smoke. As you can guess, it didn't take hot rodders long to learn that eliminating the differential allowed power to be equally applied to both wheels, and the result was better traction. Some early enthusiasts took the direct approach and simply welded the internals of the differential into a solid mass; the result was a locked rearend that tied both rear wheels together.

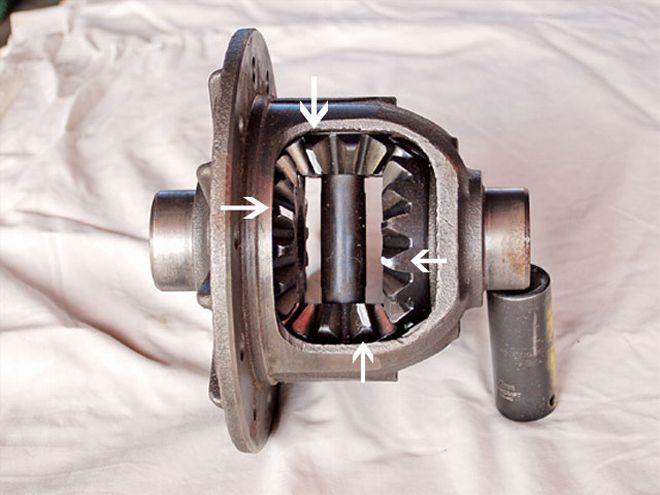

When a car with an open differential negotiates a corner (or one wheel loses traction), that axle turns faster. As a result, the spider gears spin on the shaft (note the alignment marks again arrows).

When a car with an open differential negotiates a corner (or one wheel loses traction), that axle turns faster. As a result, the spider gears spin on the shaft (note the alignment marks again arrows).

Granted, welding the differential gears together was crude, but it was effective. There is a more sophisticated means of eliminating the differential, however; it's with something called a spool. Spools are used in many drag race cars; they replace the differential assembly and mount the ring gear, connecting both axles solidly together. And while they work great in a straight line, going around corners is another matter. Imagine what would happen in our overhead view scenario of your car turning in a circle if both drive wheels were locked together. The inside wheel would turn as fast as the outside wheel and that would mean something would have to give-the inside tire would have to spin on the pavement, the car would try to go in a straight line rather than turn, or more than likely, there would be a combination of both taking place. A Sprint Car that slides around on a dirt track, or a drag racer that goes mostly in a straight line won't have problems with a spool, but street cars will.

Open Differentials

The rearend of a car serves a number of functions in a front-engine, rear-wheel-drive configuration. It provides the final gear reduction with the ring-and-pinion, turns the power 90 degrees from the driveshaft to the axles, and it contains the differential.

About as simple as things can get, a spool eliminates any sort of differential.

About as simple as things can get, a spool eliminates any sort of differential.

In a standard differential the pinion gear turns the ring gear, which is mounted to the differential case. The ends of both axles slide into the case and engage what are called side gears. Now here's where things get interesting. The axles and side gears are not attached to the case. Another set of gears, commonly called spiders, is hooked to the case by a shaft; it's these gears that engage the side gears on the axles.

When the car is going down the road in a straight line, power from the ring gear is delivered through the case and spider gears to the side gears on the axles. When the side gears are both turning the same speed, the spiders remain stationary on their shaft. But when the car goes around a corner, or one wheel loses traction, the axles, and as a result the side gears, begin turning at different speeds. At that point the spiders compensate by spinning their shaft. That's how one wheel can turn faster than the other and also why all the power goes to the wheel without traction.

Eaton's Posi is easily identifiable by the springs that preload the clutch discs. This is the same unit that was standard on GM products in the 1960s and 1970s.

Eaton's Posi is easily identifiable by the springs that preload the clutch discs. This is the same unit that was standard on GM products in the 1960s and 1970s.

Traction-Control Differentials

Basically there are two types of traction-enhancing differentials-limited slip and locking. Limited slip responds to the amount of torque being applied, and locking rearends respond to the difference in wheel speed.

Over the years there have been a number of companies producing variations of both types. Eaton limited-slip rearends were first introduced in 1961 on half-ton GM pickups, and cars shortly thereafter, and just about every rodder has heard of the Detroit Locker. Recently the Eaton Corporation acquired the parent company that makes the Detroit Locker and Detroit Truetrac. Along with the Eaton Posi limited-slip differential and the Eaton Elocker electronic locking differential, Eaton has just about covered all the bases.

The clutch discs can be seen in this exploded view of an Eaton Posi. These units require special lubricants to prevent the clutches from sticking.

The clutch discs can be seen in this exploded view of an Eaton Posi. These units require special lubricants to prevent the clutches from sticking.

Limited-Slip Differentials

Limited-slip differentials come in various designs, but they all react to the amount of torque applied to them.

Inside the Eaton Posi case are clutch packs and springs. When torque is applied to the differential and both wheels have traction surface, the clutch packs clamp the side gears to the differential case. This clamping action is directly related to the torque being applied-more torque means higher clamping force (the Eaton Posi essentially prevents wheel spin before it happens). However, when one tire does begin to spin, the clamping force is reduced; consequently, the torque to that wheel is reduced. When it comes time to turn a corner, the clutch discs allow the slippage necessary to allow the axles/wheels to turn at different speeds.

A variation on the limited-slip theme is the Truetrac. These are unique in that they are gear-type limited-slip design with no clutch or friction plates, so there is nothing to wear out.

In operation, the Truetrac's side gears and the differential's worm gears are forced away from each other. Similar to the clutch-style unit, this action clamps the axle to the differential case. So, if one of the tires loses traction, the friction between the worm gears and the case is reduced, and power to that wheel is reduced.

Here we have a Detroit Gearless differential. The cross pin connects the unit to the differential case.

Here we have a Detroit Gearless differential. The cross pin connects the unit to the differential case.

Limited-slip rearends are relatively seamless in operation; they're quiet and smooth, and you'll never know they're there until you need them. However, be aware that most clutch-style limited-slip differentials require special gear oil or an additive. Always check with the manufacturer for their recommendations on lubrication.

Locking Differentials

When it comes to the ultimate in traction, lockers are hard to beat. This style of differential is speed sensitive; that is, both wheels are locked together until one rotates faster than the other.

The venerable Detroit Locker uses what's called a dog clutch to deliver power to each wheel. When one wheel goes faster than the other, as in turning a corner, the unit disengages the outside wheel (or the one without traction) and sends all the power to the inside wheel (or the one with traction).

Although Detroit Lockers are indeed effective, they can be somewhat disconcerting to live with. While a locker is said to disengage during cornering, the action of a dog clutch can be sudden and abrupt. Lockers can be noisy and will make metallic sounds when the throttle is applied and released, or when they release and lock up during cornering. Finally, drivers of short-wheelbase cars may notice some slight twitching in corners as the unit locks and unlocks. Some find it objectionable, others don't.

For those who want the advantages of a locker without some of the rough edges, Eaton also offers the Detroit SofLocker, which uses what are called preload springs to dampen much of the operational noise.

Detroit Gearless

Similar to the Detroit Locker, the Gearless drives both wheels unless there is a difference in wheel speed. But, while the Detroit Locker and the Gearless perform similarly, their internal components are quite different.

The Gearless uses what's called a Tunkenel-V ramp design. At the heart of the system is a cross-shaft located between two V-shaped ramps. The V ramps are forced apart as the differential case turns the shaft, which causes the friction clutches to lock the side gears to the case and transfer torque to the wheels. If any force causes one wheel to go faster than the ring gear that is driving it, like turning a corner, the force on the V decreases and the clutches disengage. Trust us, it's simpler than it sounds.

Eaton E-Locker

Think of this as a locker you can turn on and off at the flick of a switch. When the system is engaged, an armature and an electromagnet apply force to what's called a ball ramp mechanism. Balls are forced up a ramp, which push locking pins into matching holes located on the back of the side gear. That locks the axle and drives torque to both wheels. That action, in turn, pushes the system's locking pins into matching holes located on the back of the side gear. That locks the axle, and drives torque to both wheels.

There are certainly advantages to a locker that can be turned on or off, but then you don't always know when you'll need extra traction until it's too late.

So, Which One Is For You?

An open differential is perfectly acceptable for some street rodders, but if a performance engine and transmission are part of the package, as they often are, a traction-enhancing differential should be part of the package as well.

So which one is right for you? That depends on your expectations. If ultimate traction is the goal, a locker is the way to go. In the case of a conventional design, there are some noise and cornering quirks to contend with; and with an electric locker, you obviously have to turn it on when you need more traction, which may be great when you decide to go drag racing but a little impractical for everyday use. On the other hand, if improved traction with no muss or fuss is what you want, a limited slip of some sort is the way to go. In either case, the performance benefits are obvious, but then you learned that as a kid.