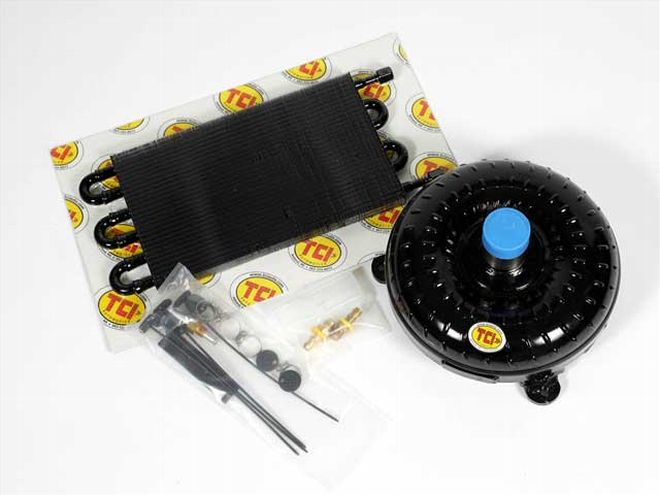

TCI's super-efficient 10-inch racing torque converter helps reduce rotating mass hanging off the crankshaft while improving the amount of horsepower that makes it through the transmission to the rear wheels. In any racing application with an automatic transmission, an oil cooler is also recommended to improve component life.

TCI's super-efficient 10-inch racing torque converter helps reduce rotating mass hanging off the crankshaft while improving the amount of horsepower that makes it through the transmission to the rear wheels. In any racing application with an automatic transmission, an oil cooler is also recommended to improve component life.

Several years ago, the idea of going circle track racing with an automatic transmission in your car was considered lunacy. Automatic transmissions back in the day weren't called "slush boxes" without a reason--they were inefficient, killed throttle response, and were a big horsepower drain.

Today, automatic trannies in race cars have become much more common as a way to keep costs down. Since it's nearly impossible to find a Monte Carlo (or any other GM metric chassis for that matter), a Thunderbird, or a Taurus with a stick, pulling a car out of a junkyard to transform it into a race car means you are also getting an auto tranny. To save money for racers in the lower classes, the rule books simply state that you have to race what came with the car--and that means the automatic transmission is now part of the race package.

You can race a stock transmission and get by with it, but there is no way a stock piece designed primarily for a smooth ride and low production costs is going to provide the same performance of a torque converter purpose-built for racing. There are other modifications that can be made to improve the performance of an automatic transmission, but swapping torque converters is by far the easiest and packs the most bang for the buck.

If you are doing a converter swap, you are going to be spending a lot of time under the car. Go ahead and raise the car on jackstands so you will have a comfortable place to work. It's safer, too.

If you are doing a converter swap, you are going to be spending a lot of time under the car. Go ahead and raise the car on jackstands so you will have a comfortable place to work. It's safer, too.

As a rule, stock torque converters are too large in diameter and too heavy. Both factors are critical in terms of performance because the converter essentially hangs off the back of the crankshaft and must be spun at engine rpm. Excess weight, especially when it's located at a greater distance to the centerline of the crank, makes it difficult for the engine to accelerate. Additionally, stock torque converters simply aren't built to withstand the additional horsepower and frequent wide-open-throttle conditions common in racing.

The Competitive Advantage

Gear specialist Jim Cook and car owner Chris Hargett remove the exhaust pipes, driveshaft, and crossmember before getting to work on the transmission.

Gear specialist Jim Cook and car owner Chris Hargett remove the exhaust pipes, driveshaft, and crossmember before getting to work on the transmission.

A torque converter that is purpose-built for racing may look similar to the stock version on the outside (except smaller), but there are many differences that make them more efficient when it comes to transferring power from the engine, through the transmission, and to the rear wheels. Proper design is critical because a torque converter has no direct mechanical linkage between its input and output portions. Instead, it uses the resistance of moving vanes through the automatic transmission fluid to provide the power linkage between the crank and the transmission. This is known as a "viscous coupling."

Before pulling the transmission, don't forget to drain the oil from the system or you could be in for a nasty surprise

Before pulling the transmission, don't forget to drain the oil from the system or you could be in for a nasty surprise

"There are several things we do to improve the performance of our torque converters over a stock unit," explains Scott Miller of TCI Automotive, one of the top manufacturers of high-performance automatic transmissions and torque converters. "All of our converters that we have for circle track applications use Torrington-style bearings instead of washers like in a stock converter. So everything turns more easily, which reduces drag in the converter and allows the engine to spin up more quickly. Combine that with the lighter overall weight and the smaller diameter of our converters, and you get significantly more power coming out of the turns.

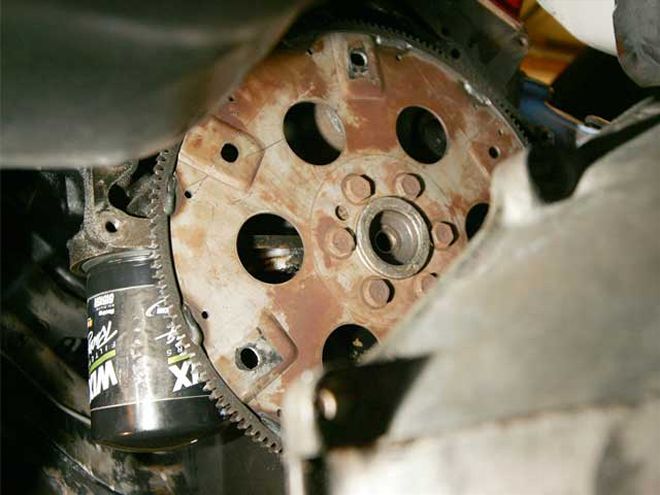

With the dust cover removed, you can see just how large the stock converter is. It connects to the engine's flexplate with three bolts.

With the dust cover removed, you can see just how large the stock converter is. It connects to the engine's flexplate with three bolts.

"A second thing we do is all of our performance converters are furnace-brazed. The pieces inside the converter are furnace-brazed, which makes the converter stronger and more efficient. Under heavy loads--such as a more powerful race motor in full acceleration--the fins inside a non-furnace-brazed converter will flex. When that happens, the converter loses efficiency and less power is put to the ground."

Understanding Stall

Support the transmission with a floor jack so you can safely lower it once it's disconnected from the chassis and engine. Cook recommends scrounging up an old driveshaft yoke for this project. When you pull the driveshaft, you can stick the old yoke into the tailhousing to keep the transmission fluid from running all over you while you are trying to work.

Support the transmission with a floor jack so you can safely lower it once it's disconnected from the chassis and engine. Cook recommends scrounging up an old driveshaft yoke for this project. When you pull the driveshaft, you can stick the old yoke into the tailhousing to keep the transmission fluid from running all over you while you are trying to work.

As a torque converter spins faster, it gains efficiency until it reaches its stall speed. "Stall" is the speed, in revolutions per minute, at which a converter gains maximum efficiency. In stock car racing, there is no purpose in racing with your engine rpm below the torque converter's stall speed, because that means you are failing to put the greatest amount of your engine's power to the ground. Also, even after you have reached the converter's stall speed, there is still a certain amount of slippage because of the viscous coupling. In this area, however, all converters are not created equal. Stock converters may allow as much as 10 percent slippage after stall, while TCI's performance converters use tighter clearances and more aggressive designs to reduce slippage after stall is achieved to between 2 and 3 percent. For a racer, that's easy math.

This is as far as the transmission needs to go in order to swap the torque converters. Of course, if you have been racing for a season or two without giving the entire transmission a good going-over, this is a good time for that, too.

This is as far as the transmission needs to go in order to swap the torque converters. Of course, if you have been racing for a season or two without giving the entire transmission a good going-over, this is a good time for that, too.

To determine your minimum stall, you must be able to predict the minimum engine speed during racing conditions. This is usually the moment you pick up the throttle on turn exit--the time you need all the engine torque available to power out of the turn. If you race a converter with a higher stall than this rpm, you are going to be giving up power on the track. The easy solution would at first seem to be to pick the lowest stall converter available, but this creates problems of its own. As the stall number drops, design requirements usually force the converter to be larger. And, as we've already discussed, a larger converter comes with a greater moment of inertia, which makes it harder for the engine to accelerate. The fight becomes a battle between lowering the stall speed and keeping off weight.

Here's a comparison of the stock converter (left) with the 10-inch TCI unit (<b>PN 242120</b>) that we are installing. Besides the obvious weight difference that comes from the differential size, the advantage of the smaller converter becomes even greater when you consider that both units have to be filled with fluid to work.

Here's a comparison of the stock converter (left) with the 10-inch TCI unit (<b>PN 242120</b>) that we are installing. Besides the obvious weight difference that comes from the differential size, the advantage of the smaller converter becomes even greater when you consider that both units have to be filled with fluid to work.

Fortunately, torque converters purpose-built for racing can be more efficient at stall and smaller than their stock brethren. Among converters with the same design, the smaller unit will always have the higher stall numbers. "Normally, the smaller the converter, the higher the stall is," Miller says, explaining how TCI can build a smaller converter with a lower stall number than most stock units. "But we can change the fin angles and modify the stator inside and actually lower the stall. That helps when comparing a stock converter that's 30-plus pounds to one of our 10-inch converters. The modifications allow us to lower the stall level, but when comparing our 10-inch converter to our 11-inch version, the bigger unit is going to have the lower stall speed."

In order to be centered, the hub of the torque converter must fit into the slot in the center of the crank.

In order to be centered, the hub of the torque converter must fit into the slot in the center of the crank.

Installation

Of course, all this sounds good, but if you cannot get it to work in your race car, what use is it? To find out, we followed Jim Cook, owner of Jim Cook Racing, as he installed a TCI 10-inch racing converter and transmission oil cooler into a customer's race car. The car is an '84 Buick powered by a Chevrolet 350-cid engine and using a Turbo 350 transmission, which is easily the most popular engine/transmission combination when it comes to classes where an automatic is required. This race car normally competes in Strictly Stock-level events.

The hub on our TCI converter was a tight fit, so Cook lightly sands away some of the paint on the hub so that it will slide into place easier

The hub on our TCI converter was a tight fit, so Cook lightly sands away some of the paint on the hub so that it will slide into place easier

The biggest trouble when it comes to installing a new torque converter doesn't have anything to do with the converter itself--it is getting all the "stuff" out of the way so you can get to the transmission. Before they could turn the first bolt on the transmission, Cook and car owner Chris Hargett had to remove the exhaust pipes, driveshaft, and crossmember, as well as all the transmission linkages. You are going to spend a fair amount of time underneath your race car for this project, so get it up on a set of jackstands so you can operate underneath the chassis comfortably and safely. The next step is to drain the fluid from the transmission and separate the transmission (including the bellhousing) from the engine at the flexplate. In our application, there were three 38-inch bolts holding the torque converter to the flexplate. Lower the transmission on a shop jack so that you can access the torque converter. The converter install is actually so easy that Cook and Hargett didn't bother pulling the transmission from under the car.

The new converter slides into place on the transmission input shaft. Remember, the converter has to attach to the transmission at three points--the input shaft, the stator support, and the front pump gear--so it may take a little finesse to get everything to fit. Apply light pressure to the converter as you spin it, and it should drop into place. Do not apply significant force, as you may damage something.

The new converter slides into place on the transmission input shaft. Remember, the converter has to attach to the transmission at three points--the input shaft, the stator support, and the front pump gear--so it may take a little finesse to get everything to fit. Apply light pressure to the converter as you spin it, and it should drop into place. Do not apply significant force, as you may damage something.

Once you have access to the front of the transmission, simply pull out the old torque converter. You may have to wiggle it a little bit to get it loose, but excessive force isn't necessary unless it is damaged. To install the new torque converter, simply slide it onto the transmission's input shaft. The converter needs to connect at three levels--the input shaft, the stator support, and the front pump gear--so you may need to spin the converter a bit to get all three engaged. You should not, however, have to bang or otherwise force the converter into position. Once it's in place, raise the transmission back into place so that the hub of the torque converter slides into the end of the crank, and bolt the converter to the flexplate.

If your race car already has an integral transmission fluid cooler in the radiator, plumbing TCI's external oil cooler is equally as easy. A cooler is highly recommended because it helps improve component life. Racing at WOT produces a lot of heat and stress, and anything you can do to keep the temperature down in the stock-based transmission will help.

You can compare this shot with the TCI converter mounted in place with the stock converter before it was removed. You will have to spin the flexplate to get to all three bolts that connect it to the converter. Do not try to spin the motor with a starter. Hargett uses a tool specifically made for this purpose. You can get by with a screwdriver, but expect some busted knuckles.

You can compare this shot with the TCI converter mounted in place with the stock converter before it was removed. You will have to spin the flexplate to get to all three bolts that connect it to the converter. Do not try to spin the motor with a starter. Hargett uses a tool specifically made for this purpose. You can get by with a screwdriver, but expect some busted knuckles.

TCI's kit provides all the fittings and hoses necessary for the install. There are two options when installing the kit. You can piggyback the external oil cooler with the existing oil cooler in the radiator. Cook prefers this method because it can actually help bring the transmission fluid to operating temperatures before the race. With the car running--even if you are sitting in the pits--the transmission may not be engaged, but the water temperature will come up to operating temperature. By running the transmission fluid through both coolers, the higher water temperature will help bring up the temperature of the fluid to give you good performance as soon as the green flag falls, but the external cooler will keep it from getting too hot under racing conditions.

You can also re-route the transmission fluid away from the radiator completely and use the external cooler to keep the temperature under control. This is Miller's preference because it both simplifies and separates the systems. "In a race application, I prefer just bypassing the radiator completely," he says. "Just run the lines straight from the tranny to the cooler and be done with it. If something ever happens and the radiator starts leaking, you will get water in your fluid and your transmission will be toast. I think it's just safer and simpler."

Overall, installation of the torque converter required less than two hours of work. The external oil cooler required another 45 minutes. At the time this went to press, Hargett had not yet raced the car with the new setup, but we'll give an update on its performance in a later issue.