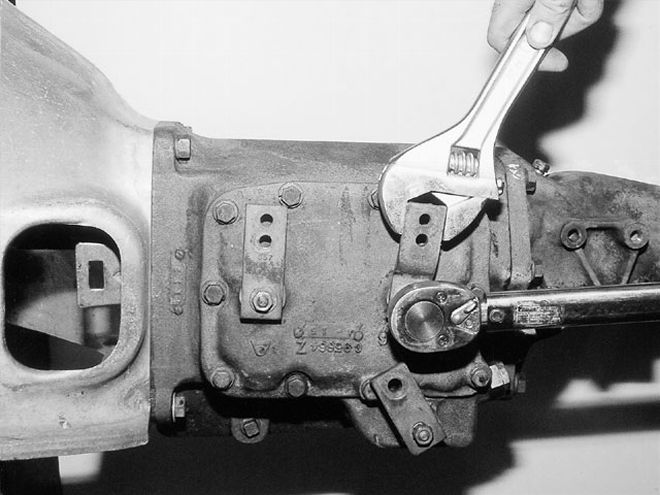

The operating levers on the trans need to be in good shape and properly torqued to specs (18 lb/ft). Loose levers will wear out the square-cut register on the shift forks where they bolt up. Support the levers with a wrench when torquing.

The operating levers on the trans need to be in good shape and properly torqued to specs (18 lb/ft). Loose levers will wear out the square-cut register on the shift forks where they bolt up. Support the levers with a wrench when torquing.

Since day one we've heard crybabies complain that the Mopar four-speed is a hard-shifting beast. Even in the old magazine road tests, references to the heavy shifting characteristics of the trans accompanied any editorial on a manual shift car. Admittedly, there was the much maligned Inland shifter from '66-early '68, instead of the slick Hurst unit, but hey, in those old road tests, the tranny was usually hardly broken in. Sure, the sheer mass of the tranny's fat-boy gears means extra force has to be exerted to swap 'em back and forth inside. Do you think the Pistol Grip shifter was designed to be handled by wimps? A seasoned but functionally fresh four-speed with the shifter properly set up, backed with a little muscle at the stick, can be power shifted as quickly as the other guys' OE four gears-just ask Ronnie Sox.

Blow it when setting up the shifter linkage, however, and that four-speed will kill you with frustration. Gear changes are via three shift rods linking the three arms of the shifter mechanism to the three levers on the tranny case, which work the shift forks inside. One of the levers operates Reverse, kicking it either in or out. The forward gear levers split duty between the remaining drive gears, with the rear lever handling gears One and Two, and the front taking care of the Three-Four shift. The moves from First to Second or Third to Fourth or back down are the more direct gear changes, since the same lever/linkage set is doing all the action. On the Second/Third shift, the shifter has to swap operating arms, and this is where a maladjusted linkage is most likely to cross-up the shift.

When the shifter is pulled back across the Neutral gate, it must reach its exact center of travel to allow the mechanism to cross over to the adjacent gate, and at the same point the shift lever at the tranny must stop at its Neutral mid-position to disengage the previous gear.

Setting up the shifter is a simple job, but it's amazing how often a shifter is just bolted up and the linkages just slid into place. There's no way to get smooth quick shifts if worn or loose parts have the system full of slop. Bent levers, stripped end swivels, a bad bushing, the wrong clips, or egged-out operating levers on the trans all need to be fixed if a smooth, quick shifting gearbox is the goal. Hard shifting, binding linkages, or even a locked-up shifter are the price for not taking a few minutes to set up the linkage. We set up an A-833 four-speed on a stand and worked out the linkage bugs before installing the tranny. Our new parts list was limited to a pack of clips and shift rod bushings from Year One. If your parts needs are more extensive, Year One can supply new shift linkages and levers for many applications, as well as rebuild your existing Hurst shifter to like-new condition.