HOT ROD’s taking parts testing to the next level. With the introduction of our HOT ROD Garage show on YouTube in 2014, we have yet another outlet for expanding performance testing of speed parts. In Episode 4 we checked out parts for high-performance braking.

Everyone is switching to the biggest brakes they can find these days, either for stylistic reasons, improved stopping power, or both. We get it. Factory muscle-car brakes were designed to function during your daily commute and the occasional panic stop. They weren’t meant to slow your ride down after a quarter-mile pass or repeated trips around cones in a parking lot. Plus, the diameter of aftermarket wheels has exploded to the point where a set of factory 10.5-inch discs from the 1960s look puny on a modern muscle car.

Our 1969 Chevy El Camino cornered well but stopped poorly, a trait we remedied in just one day of testing new brake parts and a new rearend.

Our 1969 Chevy El Camino cornered well but stopped poorly, a trait we remedied in just one day of testing new brake parts and a new rearend.

Bigger is better when it comes to binders, right? In most cases, the answer is yes. Larger-diameter rotors and calipers with more piston area do provide increased brake torque and tend to work better for longer periods of time when excessive heat is present. That extra torque and resistance to brake fade doesn’t come without a few small penalties, though. A couple of days spent at Wilwood Engineering’s headquarters in Camarillo, California, during filming of HOT ROD Garage’s Episode 4 showed us why. We tested the stock brakes on our 1969 Chevy El Camino against two sets of Wilwood’s that dwarfed the factory parts, and, yes, the stopping distance of our car dramatically improved and the brakes filled our 18-inch Forgeline DE3C Concave wheels better, but the brake swaps also opened up a small—though not insurmountable—can of worms.

The Elco was lowered a few years ago with a mishmash of aftermarket suspension parts. We upgraded the rolling stock from 17-inch steel wheels and BFGoodrich Radial T/A tires to 18-inch Forgeline three-piece aluminum rims and sticky Falken Azenis 615 tires for this brake test. Up front everything fit fine on the stock hubs and discs, and cleared the fenders with a bit of trimming of the inner fenderwells. When we bolted the new rollers to the factory GM 10-bolt rearend and drum brakes, the Falkens cleared the lips of the rear fenders without incident. Then we began testing 11-inch and 14-inch brake packages from Wilwood and found out that there are a few ancillary items that need addressing when stuffing big wheels and binders under a lowered A-body. We’ll get to that later in this story.

Our brake test was conducted by Scott Mortara and Benson Kong of Motor Trend, who were kind enough to temporarily install a Vbox data-acquisition system into the Elco. The Vbox works via a global-positioning system to accurately measure ground speed and location, acceleration, distance, slip angle, and vehicle pitch/roll angle. During the test we brought the Elco up to 65 mph, held it steady there for several seconds to ensure we were above the typical 60-mph threshold for a brake test, and then pressed the pedal, doing our best to modulate the brakes and not lock up the tires before the car stopped. The Vbox tracked the car and let us know how many feet it took to slow from 60 mph to zero.

These are OEM-style aftermarket front discs, which are built from cast-iron and weigh nearly 19 pounds each.

These are OEM-style aftermarket front discs, which are built from cast-iron and weigh nearly 19 pounds each.

The rear drums on our car hadn’t been serviced in decades. The cobwebs were the least of our worries; there was maybe 0.060 inch of shoe material left. A few more hard stops (or a few hundred miles) and these puppies would’ve been toast.

The rear drums on our car hadn’t been serviced in decades. The cobwebs were the least of our worries; there was maybe 0.060 inch of shoe material left. A few more hard stops (or a few hundred miles) and these puppies would’ve been toast.

Not only did we test a set of 11-inch Wilwood Dynalite Pro front discs (PN 140-10996-dr) and 12-inch Dynapro Series rear discs (PN 140-11398-dr) on the Elco but we left Wilwood’s Aero6 Big Brake 14-inch front kit (PN 140-10920-DR) and the Aero4 Big Brake 14-inch rear kit (PN 140-10948-DR) with internal parking-brake mechanism on the car because it worked too well to give the parts back. The Aero6 calipers contain six pistons, while the Aero4 calipers contain four pistons.

Not only did we test a set of 11-inch Wilwood Dynalite Pro front discs (PN 140-10996-dr) and 12-inch Dynapro Series rear discs (PN 140-11398-dr) on the Elco but we left Wilwood’s Aero6 Big Brake 14-inch front kit (PN 140-10920-DR) and the Aero4 Big Brake 14-inch rear kit (PN 140-10948-DR) with internal parking-brake mechanism on the car because it worked too well to give the parts back. The Aero6 calipers contain six pistons, while the Aero4 calipers contain four pistons.

Test 1: Stock-Style Front Discs/Factory Drum Rear Brakes

Total Stopping Distance: 162 Feet

With an ABSPowerBrake.com master cylinder and 11-inch booster combo, the pedal was very touchy. It took very little effort to get the car slowed down. However, it was easy to lock up the brakes and flat-spot the tires, which made it tough to get the Elco stopped efficiently or repeat the feat on a racetrack or autocross course. The 10.5-inch-diameter front discs and rear drums worked, but began fading after the third hard stop and failed to inspire much confidence when barreling into a tight corner.

The 10-bolt to 9-inch Axle Shuffle

After baseline testing, we returned to Wilwood’s R&D facility and took care of the last piece of the drivetrain puzzle: removing the stock open-diff, 3.05:1 geared, 10-bolt axle. In its place we installed a Strange 9-inch rearend, complete with 31-spline axles, a fabricated housing, nodular-iron case, and Eaton Truetrac differential with 3.73:1 gears. The unit came complete with A-body mounts, so it bolted right into place with no hassles, and because of the housing’s design, there is a greater amount of weld area around the axletubes, which yields a unit with less deflection than traditional 9-inch housings. The only hiccup, which we anticipated, was a slight variation in driveline length. The driveline had to be shortened ¾-inch, and we took the opportunity to have Coast Driveline build a new shaft to eliminate the smaller 1310-series U-joints and 3.125-inch-diameter, 0.065-inch wall tubing in favor of 1350 joints and 3.00-inch-diameter, 0.095-inch wall tubing. According to Coast Driveline, the factory driveshaft would twist into a pretzel at our modest power level if the rear tires ever hooked. The new diff helped in the traction department, while the lower gear ratio finally made the car accelerate like it actually had 420 hp under the hood. Next, it was time to see how well we could make the front-heavy car/truck stop.

The 11-inch brakes weigh quite a bit less than the stock parts, thanks to a two-piece design that contains an aluminum hub.

The 11-inch brakes weigh quite a bit less than the stock parts, thanks to a two-piece design that contains an aluminum hub.

Test 2: Wilwood 11-Inch Discs, 7⁄8-Inch-Diameter Master Cylinder

Total Stopping Distance: 138 Feet

Our test schedule meant testing both 11- and 14-inch brakes in a short time period with only enough time to change the master cylinder once. With that in mind, Wilwood installed a 7⁄8-inch-bore master cylinder, which proved to be less than optimal for the four-piston calipers in this manual brake system. Pedal feel was steady and smooth compared to the old power brakes, but we had to use almost every inch of pedal travel to get the car stopped. At first it was an unsettling feeling until we realized that we now had a brake system that was repeatable and way more resistant to fading when compared to the old parts. After a few miles of driving, we grew to like this combination of parts even if it meant that tossing the keys to an unsuspecting driver might result in a panic stop the first time they used the brakes. Wilwood recommends a 15⁄16-inch-bore master cylinder for the 11-inch discs and four-piston calipers and said this would improve the pedal feel. Regardless, these brakes are perfect for daily commuting and moderate duration high-performance driving and brought the Elco to a stop 22 feet shorter than the old brakes did. We think this setup would work well for autocross or brief time trials versus longer road-course action.

The 14-inch brakes weigh more than the old cast-iron parts, but they are a much larger part and work so much better that the penalty is worth the extra unsprung weight at each corner of the car. If you want to stop as hard as possible every time you hit the pedal, then go for the big brakes.

The 14-inch brakes weigh more than the old cast-iron parts, but they are a much larger part and work so much better that the penalty is worth the extra unsprung weight at each corner of the car. If you want to stop as hard as possible every time you hit the pedal, then go for the big brakes.

Test 3: Wilwood 14-Inch Discs, 7⁄8-Inch-Diameter Master Cylinder

Total Stopping Distance: 128 Feet

The 14-inch rotors and Aero6 calipers proved to be a better match for the 7⁄8-inch master cylinder, providing the right amount of piston surface area and a positive pedal feel. Pedal travel versus stopping power was reduced, and we could not make the brakes fade no matter how many times we mashed the pedal to bring the Elco to a quick stop. The warmer the Wilwood BP-10 pads became, the better they worked. The added weight of this system is worth the performance gain on longer, faster racetracks where maximum brake torque is required and excessive heat is generated. The 14-inch brakes stopped the Elco 10 feet shorter than the 11-inch brakes did, shaving a bus length off the original stopping distance. Both sets of Wilwoods impressed us, so by now you might be wondering just what was inside that can of worms.

In many cases, Wilwood has applications that do not require replacing the factory master cylinder and brake booster combo. We like the pedal feel of manual brakes, and by the way, our master cylinder (PN 261-13271-BK) saved 16 pounds versus the old cast-iron master cylinder and booster. Plus, it won’t rust when we spill brake fluid all over it, and we can put as big a cam inside the engine as we choose without worrying about having too little vacuum to operate a booster properly.

In many cases, Wilwood has applications that do not require replacing the factory master cylinder and brake booster combo. We like the pedal feel of manual brakes, and by the way, our master cylinder (PN 261-13271-BK) saved 16 pounds versus the old cast-iron master cylinder and booster. Plus, it won’t rust when we spill brake fluid all over it, and we can put as big a cam inside the engine as we choose without worrying about having too little vacuum to operate a booster properly.

Dig the integrated proportioning valve. Ever wonder how to set one of these up? Bed in the brake pads, then make a hard stop with the bias set 100 percent toward the front brakes. Then crank the knob to move the bias toward the rear brakes and make another hard stop. Keep adjusting the knob until the rear tires finally lock up and then back off the knob a quarter-turn.

Dig the integrated proportioning valve. Ever wonder how to set one of these up? Bed in the brake pads, then make a hard stop with the bias set 100 percent toward the front brakes. Then crank the knob to move the bias toward the rear brakes and make another hard stop. Keep adjusting the knob until the rear tires finally lock up and then back off the knob a quarter-turn.

The front-brake install is fairly straightforward. The only deviation from other kits you might be used to installing is the separate brake hat. We highly recommend using safety wire to secure the bolts holding it to the center hub.

The front-brake install is fairly straightforward. The only deviation from other kits you might be used to installing is the separate brake hat. We highly recommend using safety wire to secure the bolts holding it to the center hub.

Hurdle 1: Larger Brakes = Less Room

After flogging the 11-inch brakes, greed prompted us to leave the 14-inch brakes on the Elco, even though they presented a few packaging issues. First, the inboard outside edge of the passenger-side rotor rubbed on the factory lower control arm. We remedied the situation by grinding the end of the arm near the ball joint. Second, the separate hat and rotor arrangement of the 14-inch brakes pushed the wheels away from the chassis, increasing the track width ¾ inch per side when compared to the factory discs. The 11-inch brakes have a one-piece rotor, which saves ½ inch of track width per side. In the rear that was no problem because we had ordered our new rear axle half an inch narrower per side than a stock rearend’s 61-inch drum-to-drum width. It was an issue up front, though. The tires rubbed the inner fenderwells something fierce, and no amount of trimming to the inner fenderwells and replacing the factory hex bolts with button head bolts was going to fix the problem.

When the tires rub on a lowered muscle car, you have two options: raise the suspension or change the wheels. So we called Forgeline and assessed our options. Not only could the company re-hoop our three-piece wheels to increase the backspacing and narrow the track width but we could also swap to a wider hoop if we liked. A quick call to Ridetech Suspension CEO Bret Voelkel informed us that if we switched our factory-style, coil-spring front suspension to his company’s Level 3 coilover conversion, tubular control arms, antisway bar, and drop spindles, we’d be able to stuff a wider front wheel in there too. Wider wheels equal more contact patch and better stopping power and quicker lap times. We took Voelkel’s advice, and after the brake test, swapped in Ridetech’s coilovers and changed our wheels. We switched from 18x8s with 4 inches of backspacing to 18x9s with 5.5 inches of backspacing stuffed inside of 275/40ZR18 Falken Azenis 615K rubber up front. We left the rear wheels alone; they are 18x10s with 5.5 inches of backspacing and 295/35ZR18 Falken rubber. Nailed it! The tires do not rub the sheetmetal when rolling over speedbumps, running over railroad tracks, or barreling through sharp corners, and we didn’t have to mini-tub the back of the Elco to fit the fat rubber.

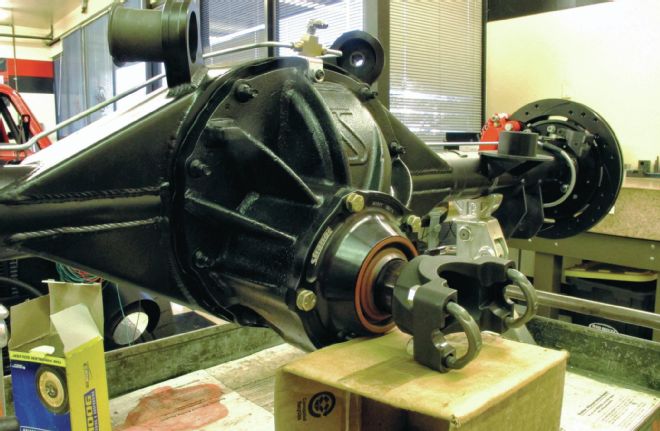

Our rear-brake install was pretty involved because we replaced the rearend at the same time. Strange shipped us the complete 9-inch rearend. All we had to do was paint the housing, press-in a set of upper control arm bushings, and bend up the rear brake lines.

Our rear-brake install was pretty involved because we replaced the rearend at the same time. Strange shipped us the complete 9-inch rearend. All we had to do was paint the housing, press-in a set of upper control arm bushings, and bend up the rear brake lines.

Wilwood did an excellent job fabricating new brake lines for the install.

Wilwood did an excellent job fabricating new brake lines for the install.

Here’s a good look at not only the integrated parking brake and stainless steel brake lines (PN220-7056) but also very clean welds on the Strange fabricated steel housing.

Here’s a good look at not only the integrated parking brake and stainless steel brake lines (PN220-7056) but also very clean welds on the Strange fabricated steel housing.

Hurdle 2: Caliper Knockback

We’d never experienced caliper knockback on one of our cars until we went deep into the second corner of the HOT ROD Garage autocross course, laid into the new brakes, and the brake pedal went right to the floor. We pumped the pedal and the brakes were functional again before corner 3, but then we lost them again in corner 4. There were no leaks and no visible signs of damage to the brake system. Wilwood’s Dustin Burr explained that the axles were shifting in our Ford 9-inch rearend and pushing the caliper pistons away from the brake pads, rendering brakes useless until they are pumped back. This is a common phenomenon with fixed calipers and semi-floating axleshafts. The solution: shim the axles to remove some of the play or switch to Wilwood’s floating caliper setup.

The nodular-iron case contains an Eaton Trutrac differential and 3.73:1 gears, which, when combined with 295/35R18 rubber and our Gearstar 4L60E transmission, yielded an almost dead-on factory speedometer calibration.

The nodular-iron case contains an Eaton Trutrac differential and 3.73:1 gears, which, when combined with 295/35R18 rubber and our Gearstar 4L60E transmission, yielded an almost dead-on factory speedometer calibration.

We had Coast Driveline replace the stock 0.065-inch wall seamed-tubing driveshaft with a 0.090-inch DOM (seamless) tubing driveshaft and 1350-style Spicer U-joints. The old 1310 U-joints and driveline were thought by Coast Driveline to only be good for about 400 hp when a car hooks up. Our new setup is said to be safe up to 1,000 hp.

We had Coast Driveline replace the stock 0.065-inch wall seamed-tubing driveshaft with a 0.090-inch DOM (seamless) tubing driveshaft and 1350-style Spicer U-joints. The old 1310 U-joints and driveline were thought by Coast Driveline to only be good for about 400 hp when a car hooks up. Our new setup is said to be safe up to 1,000 hp.

Wilwood offers four-piston calipers and six-piston calipers in both fixed-mount and floating configurations for our 9-inch rearend. After these photos were shot, we rebuilt the suspension using Ridetech’s coilover system. We still need to either shim the axles to reduce the bearing runout or swap to the floating calipers to really make this setup work properly.

Wilwood offers four-piston calipers and six-piston calipers in both fixed-mount and floating configurations for our 9-inch rearend. After these photos were shot, we rebuilt the suspension using Ridetech’s coilover system. We still need to either shim the axles to reduce the bearing runout or swap to the floating calipers to really make this setup work properly.

Throughout our testing, we used Wilwood’s BP-10 brake pads and EXP 600 Plus racing fluid (PN 290-8478).

Throughout our testing, we used Wilwood’s BP-10 brake pads and EXP 600 Plus racing fluid (PN 290-8478).

The Testbed

Our El Camino test car sat untouched for more than a decade and still had the original drivetrain intact before we got our mitts on it. In 2012 we swapped-in a 420hp, 383ci stroker small-block from Blueprint Engines during a snowstorm in Summit Racing Equipment’s Sparks, Nevada, parking lot. You can see that adventure on YouTube by searching for Roadkill Episode 4. If you collect back issues of HOT ROD, you can also find the story on the parking-lot engine swap in the July 2012 issue.

Recently, we slid the stock transmission crossmember backward in the frame and bolted-in an early model 4L60E electronic overdrive transmission built by Gearstar. You can find that story in the August 2014 issue of HOT ROD and on YouTube by searching for HOT ROD Garage Episode 1. We had horsepower, we had Overdrive—what we didn’t have was traction or stopping power.