Last month we set out to define the wheels that revolutionized the hot rod and custom car market. That's a huge subject to broach; cars have worn all sorts of wheels over the past 100 or so years. So we began where the market began: with OEM and early accessory steel wheels. Even that niche is so broad that we had to narrow our scope to include only the really noteworthy ones.

This month we're fixing our scopes on the aftermarket magnesium and aluminum wheel market. Though broad, the steel wheel segment is merely a few degrees wide compared to the alloy wheel market.

With almost no exceptions, the alloy wheel market exists exclusively as an aftermarket entity. The aftermarket relies on the publishing industry, and according to the abundance and variety of wheels made over the years, we editors did a damn fine job of helping manufacturers sell wheels.

In the late 1950s Halibrand modified its conventional 15x4 wheel with ribs and a snout for use as a spindle-mount wheel. Pete Chapouris machined the centers flat to make these wheels bolt to the hubs of the famed California Kid.

In the late 1950s Halibrand modified its conventional 15x4 wheel with ribs and a snout for use as a spindle-mount wheel. Pete Chapouris machined the centers flat to make these wheels bolt to the hubs of the famed California Kid.

For this reason we're not even going to pretend that what follows is even remotely close to comprehensive. Every time you think you've seen it all along comes another wheel that proves you wrong.

Halibrand Engineering

As far as American wheels are concerned, without a doubt all paths in the alloy wheel world lead here. Founded by a Douglas Aircraft service rep in 1947, Halibrand Engineering set the mold by making molds for the first performance-oriented American road wheels.

Ted Halibrand began making 12-inch wheels for Midget race cars. (Until then racers made their wheels by welding utility trailer rims to Model T drums.) He then cast wheels for the Rudge-derived hubs that Indianapolis roadsters used, but when he encountered wear problems in the broach, he drew upon his Midget racing roots and made his own hubs. Like the Midget hubs they engaged the wheel at six mounting points, and like the Rudge hub one oversized fastener held the wheel tight. The six-pin knock-off wheel prevailed in nearly every form of racing for decades thereafter.

According to Bob Falcon, Halibrand had the patterns modified for brake ventilation. Also according to Falcon, Halibrand referred to them as brake vents and not kidney beans or slots. These are on Sam Conrad’s (L.A. Roadsters) Olds-powered 1929. Again, Real Rodders Wheels reproduces this in aluminum.

According to Bob Falcon, Halibrand had the patterns modified for brake ventilation. Also according to Falcon, Halibrand referred to them as brake vents and not kidney beans or slots. These are on Sam Conrad’s (L.A. Roadsters) Olds-powered 1929. Again, Real Rodders Wheels reproduces this in aluminum.

Halibrand made wheels for pretty much every form of auto racing in America: Midgets, Sprint Cars, Champ cars, IndyCars, Formula 1 cars, Le Mans cars, and even the Cobra rode on lightweight Halibrand wheels. The array is staggeringly diverse: Halibrand's pattern makers altered wheel designs to meet racers' seemingly infinite array of needs.

There is only one thing consistent among Halibrand wheels made when Halibrand owned the company: magnesium alloy, the lightest of the light metals. In fact, the material is so esteemed that it serves as the inspiration for "mag", a term that incorrectly gets applied to any non-steel wheel. It's a good idea to have any vintage Halibrand professionally crack tested, not because magnesium is inherently crack prone but because of the rough lives most of these wheels lived.

Halibrand changed hands a number of times and briefly belonged to Tom and Harry Jackman of Jackman wheel fame. Despite folklore that even I once (and regretfully) helped propagate, the Jackmans did not repurpose any of the Halibrand patterns as firewood. Subsequent owners did cast wheels from aluminum under the Halibrand Engineering name for a limited time.

These solid examples represent the first wheels Halibrand produced for bolt-on applications. The company began casting them in the mid 1950s for drag racers from the same patterns it used to create its Sprint Car wheels. They were available in 15-inch diameters from 4 to 8.5 inches wide. Real Rodders Wheels reproduces this in aluminum.

These solid examples represent the first wheels Halibrand produced for bolt-on applications. The company began casting them in the mid 1950s for drag racers from the same patterns it used to create its Sprint Car wheels. They were available in 15-inch diameters from 4 to 8.5 inches wide. Real Rodders Wheels reproduces this in aluminum.

Halibrand lives on officially as Halibrand Performance. Its owner, Richard LeJuerrne, casts new aluminum wheels from a combination of original patterns and new dies. Eric Vaughn as Real Wheels produced interpretations of Halibrand's wheels. Pat O'Brien purchased the company, renamed it Real Rodder Wheels, and casts an expanded catalog. Progressive manufacturing techniques increase casting density, a feature that makes the wheels stronger and hold a polish longer.

The other spindle-mount wheel Halibrand cast owed its existence to nothing else; it was its own design that worked only as a spindle-mount wheel. Real Rodders Wheels and Team III offer bolt-on aluminum versions of this.

The other spindle-mount wheel Halibrand cast owed its existence to nothing else; it was its own design that worked only as a spindle-mount wheel. Real Rodders Wheels and Team III offer bolt-on aluminum versions of this.

American Racing Equipment

Probably no other part is as immediately recognizable as the five-spoke wheel that American Racing Equipment introduced in 1960. Though copied with impunity, the company gets the ultimate honor: show any enthusiast a copycat five-spoke wheel and chances are they'll identify it as a Torq-Thrust.

Though American Racing Equipment owes its legacy to its founder, Romeo Palamides, Palamides owes the wheel that put him on the map to circle-track legend Rolla Vollstedt. Vollstedt had wood patterns made to cast a dished magnesium wheel. "My wheels were just solid, they had no spokes," he says. "I had the pattern made so I could put a spacer in and make the wheel an inch wider, you know so I could run them on the front or rear.

In 1966 American Racing machined the Torq-Thrust spokes for caliper clearance. That year it created the Torq-Thrust D, a wheel whose curved spokes clear larger Corvette calipers. This is the somewhat faithful version that American introduced in 1988.

In 1966 American Racing machined the Torq-Thrust spokes for caliper clearance. That year it created the Torq-Thrust D, a wheel whose curved spokes clear larger Corvette calipers. This is the somewhat faithful version that American introduced in 1988.

"But then I found that I could buy them ready-made from Halibrand for less than it cost me," he says. "I sold my patterns to a guy down around the Bay Area named Romeo Palamides." Palamides made them his own by first adding material to create trapezoidal holes in the wheel face and further widened the wheels.

When they debuted on Palamides' handsome dragster that graced the cover of the Nov. '56 Hot Rod, Palamides Racing Equipment was born. When Palamides asked to be cashed out so he could go racing, machinist Jim Ellison and engineer Tom Griffith changed the name to American Racing Equipment.

American Racing introduced dozens of wheel variations over its long and storied history—far too many than we can honor here. It still produces relatively faithful copies of many of its most famous wheels to this day.

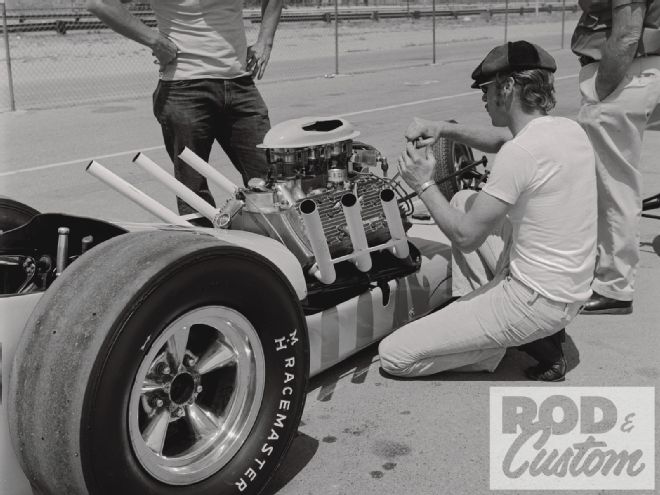

American’s second iconic wheel is the 12-spoke. Spindle mounted and lacking provisions for brakes, it’s drag-only equipment though later it caught on among T-bucketeers. The first was 15x3.5 but they grew to 18x2. All are magnesium. Several companies produce aluminum variations on this design.

American’s second iconic wheel is the 12-spoke. Spindle mounted and lacking provisions for brakes, it’s drag-only equipment though later it caught on among T-bucketeers. The first was 15x3.5 but they grew to 18x2. All are magnesium. Several companies produce aluminum variations on this design.

The Torq-Thrust R wheel came out in 1969. It features straight, highly peaked spokes and a snap-in center cap. The T70 wheel that American introduced the following year (and reissued recently) resembles it but has a perimeter flange around each spoke.

The Torq-Thrust R wheel came out in 1969. It features straight, highly peaked spokes and a snap-in center cap. The T70 wheel that American introduced the following year (and reissued recently) resembles it but has a perimeter flange around each spoke.

Wheel Centre Co. and E-T Wheels

In 1960 schoolteacher Dick Beith started making wheels in his shop class. In 1962 he founded Wheel Centre Co. Though his first production wheel resembles the American Racing Torq-Thrust, Beith was a true pioneer. For one, he produced his E-T Mag in aluminum four years before American did (yes, we recognize the irony of calling an aluminum wheel a mag). But probably his single greatest contribution was one of the most significant for its time: rather than drill each wheel with a specific pattern the company cast five slots and employed offset washers to adapt it to vehicles with 4.5-, 4.75-, and 5-inch wheel-mounting patterns. Though looked down upon by purists, Beith's Uni-Lug pattern revolutionized the aftermarket-wheel industry by reducing retailers' inventory and making wheels more available for less cost.

Typical for manufacturers riding the "big wheel" trend of the 1960s, Beith's company expanded to create several varieties. It also regularly improved the design, adopted die-casting, and employed higher-tech alloys among other things. In 1967 it introduced the E-T II, a most curious wheel that paired the outer half of a cast five-spoke wheel with the inner half of a steel rim.

The E-T V wheel (so named for its spoke count) was Dick Beith’s first wheel and remains one of Team III Wheels’ most popular models. Early examples were sand-cast but die-casting techniques make them more precise and able to withstand greater abuse. Team III produces this wheel in various diameters; 17 inch shown here.

The E-T V wheel (so named for its spoke count) was Dick Beith’s first wheel and remains one of Team III Wheels’ most popular models. Early examples were sand-cast but die-casting techniques make them more precise and able to withstand greater abuse. Team III produces this wheel in various diameters; 17 inch shown here.

Scott Russell at Team III Wheels still produces Beith's most enduring wheels. Like Beith, Russell casts the wheels in permanent molds for increased strength, detail, and shine retention. He also forewent the Uni-Lug mounting drills each wheel for a specific pattern.

Beith produced a wheel with no drop center to prevent racing slicks from coming unseated at speed. The original E-T III comes apart at the middle for tire mounting. Team III’s one-piece version, the Fueler, features a conventional drop center for conventional mounting. It’s also available in a range of sizes. Russell has the patterns to cast the original wheels if demand justifies it.

Beith produced a wheel with no drop center to prevent racing slicks from coming unseated at speed. The original E-T III comes apart at the middle for tire mounting. Team III’s one-piece version, the Fueler, features a conventional drop center for conventional mounting. It’s also available in a range of sizes. Russell has the patterns to cast the original wheels if demand justifies it.

Ansen Automotive Engineering

Upon returning from the service after World War II, Navy machinist Lou Senter went to work for speed merchant and mechanic Eddie Meyer. In 1947 he partnered with his brother Sol to open Senter Engineering. In 1948 the Senter brothers and Jack Andrews combined their efforts and their names to form Ansen Automotive Engineering.

According to Lou Senter, by the mid '50s Ansen offered 1,000 part numbers. More incredibly, Ansen made most of those parts. The shifters, pedal assemblies, and engine-mounting kits alone turned garden-variety mechanics into hot rod legends across the country.

Ansen produced several wheels. The Top Eliminator capitalized upon the Torq-Thrust design but featured rounded spokes. The seldom-seen Arrow resembled the Top Eliminator but had an oversized snout. The novel Apollo capitalized upon the Arrow's larger hub by using a wing nut to fasten the wheels to steel hubs that bolted to the car. It was a true knock-off design, something that appealed to his Sprint Car roots.

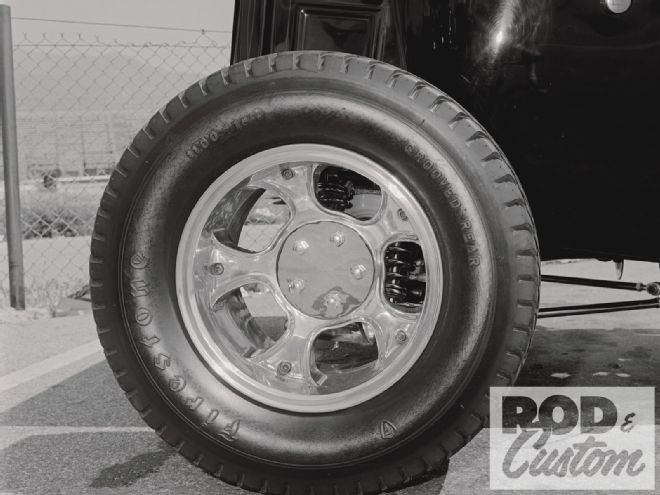

The 18x3 12-spoke wheel Radir makes differs in several key ways: its aluminum composition holds a polish better and an oversized boss accommodates a disc brake. Radir offers it as-cast and fully polished to fit early Ford, early Chevy, and Total Performance spindles. Next month we’ll feature more Rader/Radir wheels and their inspiration, Dick Rader’s Wheel Corp of America wheels.

The 18x3 12-spoke wheel Radir makes differs in several key ways: its aluminum composition holds a polish better and an oversized boss accommodates a disc brake. Radir offers it as-cast and fully polished to fit early Ford, early Chevy, and Total Performance spindles. Next month we’ll feature more Rader/Radir wheels and their inspiration, Dick Rader’s Wheel Corp of America wheels.

Though relatively successful, Senter admitted that he needed to produce his own wheel. He once again drew inspiration from his circle-track exploits, this time by loosely basing his design on Halibrand's highly esteemed wheels. "I just machined off the rib around each hole in his wheel," he admits. "If you look at them, Halibrand's wheels have an oval hole behind that lip. That's my wheel."

Of course that's the grossly oversimplified version. What Senter did was bring modern die-casting techniques to bear on an old profession. By centrifugally casting the wheels with high-strength alloys he created wheels as strong as they were beautiful for less time and money than typical sand-cast wheels cost. He named the new wheel the Sprint in honor of its background.

Like the Torq-Thrust, the Ansen Sprint is one of the most copied wheels in the industry, a sign of a good idea for sure. American Racing currently produces a range of Sprint sizes.

Rocket Racing Wheels

The wheels Rocket Racing Wheels released in the 1970s existed as interpretations of popular models, primarily the Cragar Super Sport. As interest died out for composite wheels in the 1980s and 1990s so did demand for Rocket's products.

Recently David Coker, brother of Coker Tire's Corky Coker, resurrected the Rocket brand. Only instead of resurrecting the obsolete parts with it, he struck the company in a new mold by literally making new precision molds.

Rocket created several original wheel designs but it also produces interpretations of enduring wheel styles. The company drills the wheels for 4.5, 4.75, 5, and 5.5 patterns to use conventional 60-degree conical-seat bulge lug nuts. All wheels are available with a cast-style finish or fully polished and some like the Launcher and Igniter feature a cast-style center and machined lip.