Triumph Of The Wheel

Two months ago we set out to do something we thought was pretty noble: define the wheels that revolutionized the hot rod and custom car market. It really did seem like a good idea to open peoples’ eyes to their options.

In retrospect it was probably pretty ambitious, if not entirely foolish. Even though we bookended our list at 1932 and about 1970 we still nearly became buried in a figurative avalanche of wheels. It proved exceedingly difficult to limit ourselves. Consider our quandary: We know it’s silly to show obsolete wheels but at the same time it’s boring to limit the discussion to nothing but the commercially available ones.

In the end we parsed the body of wheels into three entries. We covered the OEM and early accessory steel wheels in August. Last month we showed the aftermarket magnesium and alloy wheels. And that leaves this month pretty well defined.

But defined by what? The following wheels don’t really fit well into any single category. What makes most so ambiguous is their composition: They’re made of steel and aluminum, hence the composite term. Though the remainder are steel, they don’t fit well in the first entry, as none were officially offered as OEM parts or through a formal dealer network. And a few have a special personality: Their rather generic basic designs can be readily altered to address a buyer’s specific wants and needs, hence the modular term.

Before we begin, understand a few things about these wheels. For one, most existed as economical alternatives to performance-specific wheels; sourcing the largest part of their construction from the production world (the steel rim) kept the prices low. For another, those steel rims make most of these wheels no lighter than OEM-based steel wheels of the same size (in fact, most are considerably heavier). In other words, they existed exclusively as decorations.

If you go by how well these wheels sold, decoration was exactly what the average enthusiast wanted. People seemingly couldn’t get enough of these wheels and as a result the market flourished. In fact one could argue that these orphan wheels put the aftermarket on the map faster and more successfully than any other single part in our industry. After all, manufacturers offered these wheels to fit just about any car, and every potential home needed four of them.

And most of all, this is where the entries get interesting. In the wheel world these examples are akin to the crazy-looking, deep-sea species that fishermen occasionally snare. Only a few of you will recognize these wheels. We promise you that much.

Wheel Centre Co.

Pardon the unrevealing image but shots of the first Wheel Centre Co. wheels are rare and these are literally the very first ones on John Mibelli’s El Camino at the 1962 Grand National Roadster Show. The center is flat and the cap (not shown here) pushed in from the back.

Pardon the unrevealing image but shots of the first Wheel Centre Co. wheels are rare and these are literally the very first ones on John Mibelli’s El Camino at the 1962 Grand National Roadster Show. The center is flat and the cap (not shown here) pushed in from the back.

Inspired by his gearhead students’ aspirations to own then-exotic American Racing wheels, high school shop class teacher and Bonneville racer Dick Beith got an idea to reinvent the wheel itself. “I thought about it and the only difference between a mag wheel and a stock wheel is the center, or the spider as they called it,” he says. “So I thought, if I just made a center piece and put it in a steel rim I’d have the look for way less.”

And that’s exactly what he did. “I made the wooden patterns in the shop class after school and had a foundry make the castings,” he continues. Though he didn’t realize it at the time, the zinc-rich Tenzaloy 713 that the foundry used came to define the alloy wheel market in the ’60s: it cast well, polished to a magnesium-like shine, and achieved 80 percent of the strength of 356-T6 aluminum but without the costly heat-treating process. “The silly thing is that name later became the nickname for the wheel,” he recalls. “‘Hey, he’s got Tenzaloys on it!’ they’d say.”

Fenton, manufacturer of everything from manifolds to shifters, produced the Road Runner, a wheel that resembles the first Wheel Centre Co. wheel but with “webbed” spokes. Radir Wheel began reproducing it as a one-piece aluminum casting in 1995 and still offers it today.

Fenton, manufacturer of everything from manifolds to shifters, produced the Road Runner, a wheel that resembles the first Wheel Centre Co. wheel but with “webbed” spokes. Radir Wheel began reproducing it as a one-piece aluminum casting in 1995 and still offers it today.

Beith acquired the rims by cutting the centers out of OEM wheels, welding the rivet holes shut and grinding them smooth, and having the same shop that polished the centers also plate the rims. “We drilled the spokes and the rim and bolted them together,” he says. Wheel Centre Co. and the composite wheel were born.

“I made four wheels and put ’em on one of my students’ cars,” he continues. “We went to the Oakland Roadster Show on set up night and found a guy who had plain steel wheels on his car. ‘Hey, you wanna swap wheels for the show?’ I asked him. We jacked up his car on the show floor and ours in the parking lot and swapped wheels. Then I went down and had some brochures printed and handed them out.”

Wheel Centre Co.’s most famous wheels are its E-T variants. These were also cast as a one-piece aluminum wheel but the most common variant is a die-cast face that has an integral steel ring that welds to a steel rim. The Fenton Ram Rod, Mickey Thompson MK-II, and JC Penney Foremost resemble these but have peaked spokes.

Wheel Centre Co.’s most famous wheels are its E-T variants. These were also cast as a one-piece aluminum wheel but the most common variant is a die-cast face that has an integral steel ring that welds to a steel rim. The Fenton Ram Rod, Mickey Thompson MK-II, and JC Penney Foremost resemble these but have peaked spokes.

The brochures worked probably better than he anticipated. “Dick Rader chased me down and said, ‘Hey, you got a good idea; let’s get together.’ Instead he went to L.A. and teamed up with Mickey Thompson and away they went.” (More on that later.)

Though Wheel Centre Co. later produced all aluminum wheels, it pioneered another notable composite design. “One-piece wheels are really expensive and time intensive and we were always back ordered,” he says. So he came up with another center design that had a false aluminum “lip”. “It disguised the whole rim part; it looked like a one-piece aluminum rim,” he notes. And by having a steel ring cast in the outer perimeter of the casting it could be quickly welded to a steel rim. “We could squirt those out real fast,” he enthuses.

Rader, Mickey Thompson, and Wheel Corp of America

The recently revived Rocket Racing Wheels brand produces a similar one-piece aluminum variant of the original Rader. Rather than taper to an end, the spokes merge into a raised center-cap boss.

The recently revived Rocket Racing Wheels brand produces a similar one-piece aluminum variant of the original Rader. Rather than taper to an end, the spokes merge into a raised center-cap boss.

You could say Dick Rader was destined to build wheels. Wheel is in his name after all (räder is plural for wheel in German). According to Rich Conklin at Radir Wheels (no relation), Rader began producing wheels by at least 1962 and possibly 1961. The Single Rib as Rader called it featured five flat spokes, each adorned with, well, a single rib down the middle.

As Beith mentioned, Rader teamed up with the highly competitive Mickey Thompson. Producing wheels in Long Beach under the name Wheel Corp of America, they produced an incalculable number of wheels in what almost seems like as many styles.

In 1965 Mickey Thompson touted five new wheels in its Challenger line, among them the three-rib wheel that it referred to as the Mag Alloy Type or Mag Type No. 1, depending on the advertisement.

In 1965 Mickey Thompson touted five new wheels in its Challenger line, among them the three-rib wheel that it referred to as the Mag Alloy Type or Mag Type No. 1, depending on the advertisement.

A promoter at heart, Thompson brought an intense level of marketing sophistication to bear on the wheel world. Wheel Corp wheels appeared everywhere, including the two most widely seen places in the ’60s: on the Batmobile and in Sears catalogs.

Like other wheel designs, they also appeared as knock-offs. Speed Engineering produced a version of the single-rib. Former distributor Trans American Products in nearby Long Beach produced a copy that it called the Radar. Even the model number is an anagram of Rader’s.

In 1965 Wheel Corp reinvented the ever-popular wire wheel as a low-maintenance alloy. The design was far more attractive than the name: Space Age Wire Wheel Look Rader. Trans American Products sold a similar-if-not-identical version by 1968.

In 1965 Wheel Corp reinvented the ever-popular wire wheel as a low-maintenance alloy. The design was far more attractive than the name: Space Age Wire Wheel Look Rader. Trans American Products sold a similar-if-not-identical version by 1968.

Astro Wheel

Astro Enterprises in Gardena, California, was one of the earliest entries in the wheel market. According to advertisements it established its footing in approximately 1962 with a dished-face modular wheel called the Custom. Though two pieces, the wheel was welded and ground on its face to appear as if it were a one-piece cast-aluminum wheel like the Ansen Sprint that followed (interestingly Astro cast an aluminum version that reportedly preceded Ansen’s). It later produced the Super Custom, a variant of the custom that had a disc welded to its face to fortify the wheel hub’s integrity.

Though it built more dished wheels than anything else, Astro is most famous for an all-steel wheel that resembles Wheel Centre Co.’s first composite models. Oddly enough, the most familiar bullet-spoked version was the revised model introduced in about 1965; the original design that dates to at least 1963 has five stumpy, barrel-shaped spokes that terminated at a flat hub. Even odder, enthusiasts still refer to Supreme-style wheels as Astros even though Astro ceased production sometime around the Nixon and Ford administrations.

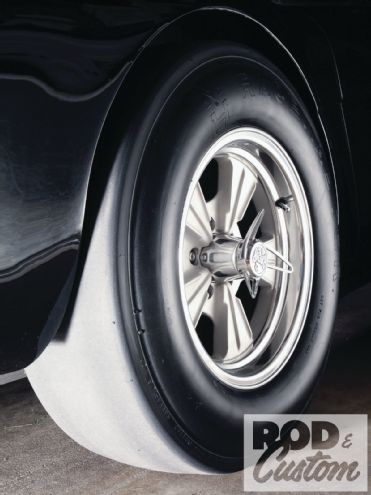

The Supreme still enjoys brisk production by several companies, including Cragar, Allied Wheel, Truespoke, and Wheel Vintiques. Though cosmetically identical not all Supreme copies are up to the task; more expensive models feature tabs welded to the back of the spokes. Many maintain that without these tabs the wheels are prone to crack. Do your homework before you buy.

Astro revised the Supreme in approximately 1965 to look like this. Again, not all reproductions are created equal; tabs welded behind the spokes of the more expensive models reportedly prevent the spokes from cracking.

Astro revised the Supreme in approximately 1965 to look like this. Again, not all reproductions are created equal; tabs welded behind the spokes of the more expensive models reportedly prevent the spokes from cracking.

Winfield Terra Thrust

To keep things concise I tried hard to stick to wheels that are still in production or turn up frequently at swaps but there are some stories about unobtainum wheels that are just too good to pass up. Car customizer, fitness nut, and all-around great guy Gene Winfield set out to produce a line of custom wheels in 1963.

You’re not likely to ever find even one of Gene Winfield’s Terra Thrust wheels but we couldn’t resist publishing this photo of Winfield himself on his shop floor with one.

You’re not likely to ever find even one of Gene Winfield’s Terra Thrust wheels but we couldn’t resist publishing this photo of Winfield himself on his shop floor with one.

“I called them Terra Thrust,” he says. “They had aluminum centers. It was a material called Tenzaloy and I had them cast. I used steel outers and I literally bolted them together—each spoke had two heavy-duty Grade 8 bolts.

“Of course I didn’t know how to market that stuff or have the money to do it so I never did anything with it.” He reportedly made 20 sets, one going to the original ‘Solar Scene’, another that went on the ‘Strip Star’, another for his ’40 Ford sedan delivery that he sold to one of Brizio’s guys, and another set that he’s using on a recreation of the Solar Scene.”

Hollywood

The Hollywood Wheel Disc Shop produced accessory wheel covers based on George DuVall’s designs, starting in the ’40s. By the ’60s, however, demand for wheel covers waned. So Hollywood did what any viable company would: It changed with the times.

This is Hollywood’s most popular wheel design. Its spokes overlap the rim’s drop center, making it one of the more distinctive five-spoke versions. Reportedly Hollywood referred to it as the Barela.

This is Hollywood’s most popular wheel design. Its spokes overlap the rim’s drop center, making it one of the more distinctive five-spoke versions. Reportedly Hollywood referred to it as the Barela.

It hired A&H Foundry in Los Angeles to cast several wheel center models based loosely on the Torq-Thrust design. Others surely sold them but Hollywood’s most visible retailer was none other than Speedway Motors.

This little gem turned up in the Car Craft archives. It’s another Hollywood wheel, this time with a cast finish, spokes that terminate conventionally at the rim, and with a more typical two-bar spinner.

This little gem turned up in the Car Craft archives. It’s another Hollywood wheel, this time with a cast finish, spokes that terminate conventionally at the rim, and with a more typical two-bar spinner.

Cragar

Named for one of its co-founders (CRAne GARtz), Cragar existed as early as 1930. Though it produced monumental speed parts like overhead-valve conversions from the Miller Schofield tooling and later belonged to Bell Auto Parts’ prolific owner Roy Richter, it made its greatest mark on the automotive industry with a wheel.

Though equipped with five spokes, Cragar’s Super Sport resembled no other model on the market. More than unique, the wheel’s shape was bolder and more purposeful looking than any of its contemporaries. Its immediate success spawned variations, including wheels with cast-finish centers, all-aluminum faces, and even other original designs.

Dozens of manufacturers rode Cragar’s wave with their interpretations. Shown here is a Western but others like Rocket, Chariot, Appliance, JC Penney (El Tigre II), and even Mr. Gasket got in on the act.

Dozens of manufacturers rode Cragar’s wave with their interpretations. Shown here is a Western but others like Rocket, Chariot, Appliance, JC Penney (El Tigre II), and even Mr. Gasket got in on the act.

Cragar’s competitors confirmed the wheel’s success by producing countless knock-offs of the design. Whether identical or merely loosely based on the original design, these copies validated the original. They also proved that there’s something immortal in the design: The wheel enjoys 49 years of uninterrupted production and as much popularity today as it did when first released.

With a bare rib around a small snap-in cap, the all-steel Smoothie wheel can’t be mistaken for anything else. You probably know that it’s a solid-faced version of the Rallye wheel that Chevrolet introduced in 1968. But did you know that Cragar was the first to make it and the bare cap? It dates to at least 1969 and just about every wheel shop offers a version.

With a bare rib around a small snap-in cap, the all-steel Smoothie wheel can’t be mistaken for anything else. You probably know that it’s a solid-faced version of the Rallye wheel that Chevrolet introduced in 1968. But did you know that Cragar was the first to make it and the bare cap? It dates to at least 1969 and just about every wheel shop offers a version.

Appliance Plating also produced an OEM-inspired disc wheel. It’s smooth but unlike the Smoothie its face is rather steep and lacks the ring around the cap. It also uses a small-diameter Appliance-specific cap and its obsolete status makes it very difficult to piece together a complete set.

Appliance Plating also produced an OEM-inspired disc wheel. It’s smooth but unlike the Smoothie its face is rather steep and lacks the ring around the cap. It also uses a small-diameter Appliance-specific cap and its obsolete status makes it very difficult to piece together a complete set.

Keystone Kustomag/Klassic

In 1964 auto parts distributor Keystone introduced another composite-wheel variation with five-scooped edge spokes that tapered and rose dramatically toward the center of the rim. Christened the Kustomag, the wheel proved incredibly popular from the start.

The Kustomag and Klassic have one thing in common: the trademark scooped-edge spokes that rise dramatically to the center cap. However, the Kustomag differs in one way: The spokes remain independent of each other.

The Kustomag and Klassic have one thing in common: the trademark scooped-edge spokes that rise dramatically to the center cap. However, the Kustomag differs in one way: The spokes remain independent of each other.

Though initially quite popular, the Kustomag didn’t enjoy the same lifespan as Cragar’s Super Sport wheel. It returned a number of times, each bearing a subtle variation or name change.

When the Kustomag reappeared as the Klassic in the ’70s its spokes transitioned to a perimeter ring that connects them to each other. The transition and ring adds to the wheel’s visual weight, but it’s better than nothing.

When the Kustomag reappeared as the Klassic in the ’70s its spokes transitioned to a perimeter ring that connects them to each other. The transition and ring adds to the wheel’s visual weight, but it’s better than nothing.

Like most vintage designs the Kustomag is enjoying a modest reprise. Now produced by Carlisle Brake and Friction, the same company that produces Cragar, the Keystone Kustomag is back as the similar 32-series Klassic.

Kelsey-Hayes

Kelsey-Hayes, the company that offered wheels that we featured in the first installment of this series, never got out of the accessory-wheel business. However, the specialty wheels it offered over the years differed little from its competitors. In 1969 it broke that streak.

Kelsey offered the wheels in two flavors: in silver called the Stripper (Bad One) and in black with silver “spokes” called the Satin Stripper (Bad Two). They were available in 15-inch diameter only in 5-, 6-, and 7-inch widths. They were made in 4.5- and 4.75-inch patterns but prepare to fight with the GM Supercar crowd if you want the latter.

Kelsey offered the wheels in two flavors: in silver called the Stripper (Bad One) and in black with silver “spokes” called the Satin Stripper (Bad Two). They were available in 15-inch diameter only in 5-, 6-, and 7-inch widths. They were made in 4.5- and 4.75-inch patterns but prepare to fight with the GM Supercar crowd if you want the latter.

It introduced a series of spoke-inspired wheels with cast-aluminum faces riveted to steel rims. Initially called The Bad Ones, the wheels soon acquired the equally improbable Stripper moniker.

Though never hotly embraced by the enthusiast crowd, the Stripper wheels found somewhat comfortable homes on cars prepared by supercar dealerships like Yenko. Their production life was brief but they frequently surface at swaps.