It's said that hindsight is 20/20, but when it comes to the way street rodders view nostalgia we're often a little more shortsighted than that. Take the use of bias-ply tires as an example. They look cool, and on some cars there's just no other choice to make it right, but on the other hand there's a reason the rest of the automotive world rolls on radials. Just about every street rodder knows that radials ride and handle better, last longer, and so on, but we're willing to forget all that. However, there is one common complaint that most of us would do something about if we could and that's the vibration that can't be cured by balancing. In a nutshell the reason for this is that bias-ply tires are sometimes, well, the shape of a nutshell-they're not always perfectly round.

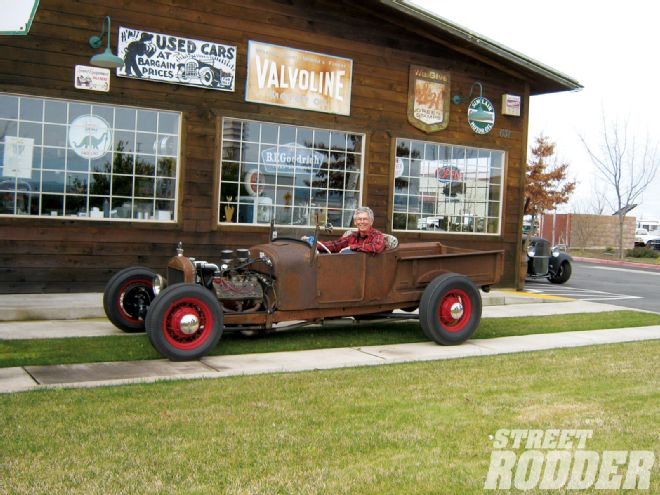

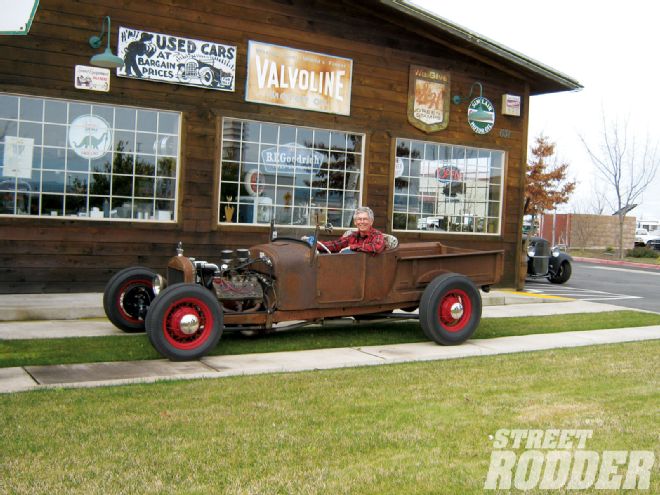

The search for a smooth ride led Russ Young and his roadster pickup from Bonneville back to his NorCal home and Dave Davidson's Vintage Hot Rod Design and Fabrication, a stone's throw away. Along with state-of-the-art equipment, Davidson also has vintage Amermac tire truing machines. Young has that big grin on his face thanks to the T's new demeanor.

The search for a smooth ride led Russ Young and his roadster pickup from Bonneville back to his NorCal home and Dave Davidson's Vintage Hot Rod Design and Fabrication, a stone's throw away. Along with state-of-the-art equipment, Davidson also has vintage Amermac tire truing machines. Young has that big grin on his face thanks to the T's new demeanor.

Russ Young has a perfect example of a hot rod that has to wear bias-ply tires; his Flathead-powered T just wouldn't be right with any other rubber. Unfortunately, the rubber it was equipped with were perfect examples of tires that would never be right. Balancing alone wouldn't get rid of a persistent vibration, but Young found the cure. During a discussion with a veteran hot rodder at Bonneville about all things vintage, Young was asked if he had shaved the tires on his roadster and was told that was the secret to a smooth ride. The problem was finding someone with the equipment to do it. Ironically, Young found that there were two Bonneville veterans practically in his backyard who had what he was looking for.

Dave Davidson and John Beck have been racing together and setting records at the Salt Flats and dry lakes for over 20 years. Davidson is the proprietor of Vintage Hot Rod Design and Fabrication in Chico, California, a 15,000 square foot facility that does everything from maintenance and repairs to ground up, turnkey cars. Beck works out of the same facility and is one of the premier engine builders in the country who can provide anything from a restored Flathead to a trophy-winning sprint car engine. To top it off, these guys have what it takes to true bias-ply tires.

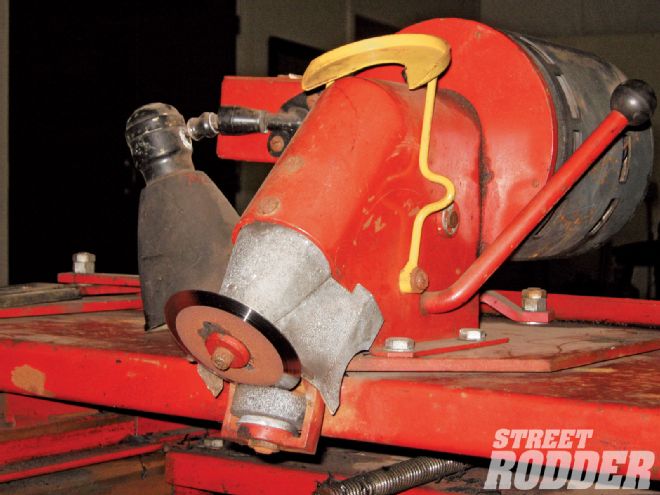

Here's the business end of the machine: the cutter. Below the blade is the sharpening stone; it's used as necessary during the cutting operation.

Here's the business end of the machine: the cutter. Below the blade is the sharpening stone; it's used as necessary during the cutting operation.

The equipment required to true out-of-round tires consists of two machines made by Amermac-one warms the tire, the other trims off the high spots and contours the tread. Once commonly found in tire shops, as bias-ply tires became far less common, the demand for tire truing and the equipment that did it faded away. As a result, many of these machines were just taking up valuable shop space and were sold for scrap. Fortunately, thanks to extremely robust construction, those machines that did survive are still capable of doing what they were designed to do. Davidson and Beck had been truing Bonneville tires for years with vintage Amermac machines, and with the growing popularity of bias-ply tires on street rods, it's a service they now offer to customers.

Truing bias-ply tires can make an amazing difference in ride quality, and the amount of rubber removed has very little impact on tread life. However, there is one caveat, the procedure is usually reserved for new tires. The presence of any foreign objects in the tread can damage the cutter, so used tires aren't normally candidates for the process. How do you know if it needs to be done to new tires? Simple enough, spin 'em and see how round they are. If they're not true you now know the cure for out-of-round rollers.

In this case, the sliding bars that position the tire were set on the number eight, corresponding with the number on the template.

In this case, the sliding bars that position the tire were set on the number eight, corresponding with the number on the template.

Amermac

A Brief History and a New Beginning

Lillian Flynt was an Amermac employee for 39 years. As she explains it, in 1959,Roy Peacock Sr. owned a tire shop in Americus, Georgia, and saw a need for tire truing. He developed tire-shaving equipment, which he had manufactured by Greenfield Metal Products (GMP), also of Americus. Peacock formed Americus Manufacturing (later Amermac) to provide development, marketing, and support for this equipment. As it grew, GMP moved about 12 miles to Ellaville. In 1979, GMP purchased Amermac. By then the "vibration correction equipment" was used by the trucking industry and had found its way into auto racing.

With the introduction of radial ply tires the need for truing declined and the equipment began to disappear from tire shops. GMP also manufactured metal closet shelving. With the severe decline in the housing market, GMP was forced to close its doors.

As Davidson looks on, John Beck carefully feeds the cutter into the tire.

As Davidson looks on, John Beck carefully feeds the cutter into the tire.

Wes Sprunk, the owner and president of TSISSG Tire Service Equipment (www.tsissg.com) had followed Amermac for years but had not been able to add it to his successful tire service equipment company. Finally, in October 2009, he was able to acquire the physical and intellectual assets of Amermac and is now making tire-truing equipment available once again.