I can’t pin point a date, but within the last ten years the Pro Touring look has become very popular with today’s classic truck enthusiasts. In the past, the Pro Touring truck look was associated with extremely lowered vehicles with airbags and larger than stock wheels. For the most part, it was a “looks thing” and the trucks were not being built to handle. Don’t get me wrong, I like slammed trucks just like the next guy, but when the ride and handling quality suffered builders started searching for other answers. Several years have passed and suspension, wheel, and tire gurus started to not only make the trucks look great but to also perform really well. This brings me to the point that a major part of the Pro Touring look has to do with wheel and tire packages. Lucky for us truck guys, we have plenty of room to work with under our fenders wheel and tire wise.

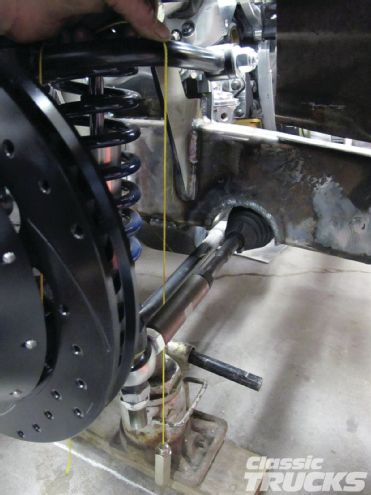

John Meadows from Deuces Wild Hot Rods and Customs and I started off by setting the truck on a jackstand. We placed a jack stand under the lower control arm so that the vehicle’s weight was on it and the suspension was at ride height. Using a drop center and soapstone John made a mark on the ground resembling the inner part of the fender.

John Meadows from Deuces Wild Hot Rods and Customs and I started off by setting the truck on a jackstand. We placed a jack stand under the lower control arm so that the vehicle’s weight was on it and the suspension was at ride height. Using a drop center and soapstone John made a mark on the ground resembling the inner part of the fender.

Why use larger wheels and tires on my classic truck?

For one they look great on classic trucks and they fill the wheelwell nicely. Larger wheels also give the option of using bigger brake kits, such as the Wilwood kit I have on my ’59 Apache. Also wheel manufactures, like Weld Racing, now offer several different wheel styles, but more importantly hundreds of different wheel size options. Rim backspacing, wheel size, and width all play a roll in overall fitment and Weld Racing has a size for just about every application. In the past tires were simply not available in all sizes and widths, but as time passed more and more tires became available to fit many different applications. As we all know, tires are not all created equal, they come in different sizes, tread, compounds and ratings just to name a few. I decided to use a set of Nitto NT05 DOT street tires. The NT05 tires are not made to get 60,000 miles because of the 200 tread rating, but if you are serious about autocross and handling then the Nitto NT05 is a perfect choice for you. The NT05s are also not made to be used to load your truck down with building material or tow a trailer, they are to be used for performance driven vehicles and should be treated as such. Nitto has other tire options such as the NT420s, INVO, or the NT555 that have great performance with less tread wear.

Next, we placed the drop center on the wheel face of the rotor and marked the ground.

Next, we placed the drop center on the wheel face of the rotor and marked the ground.

How do you measure for bigger wheels?

It’s hard to ignore that many of us get scared when it comes to using a measuring tape. It is especially true when big money is being spent on wheels and tires that may or may not fit. This brings me back to the question, how do you measure for wheels and tires? I have to answer that question with another question. What do you plan on doing with the truck? Normal Street driving, autocross, drag racing, or mud bogging? OK, the last one was a stretch but you have to ask yourself these questions in order to help yourself narrow down all that is involved. If you’re going for the Pro Touring look like I am then measuring for correct wheel spacing is very important. Does this mean I have to modify all of the suspension and do a bunch of inner fender body mods? Yes and no. First off, how big of a wheel do you want to go with? The 17-, 18-, 19-, and 20-inch wheels can fit inside most stock fenderwells if you measure correct. What front end do you have on your truck? If it is the stock straight-axle then I would suggest installing IFS before thinking about bigger wheels. Do you want to mini-tub the rear fenders? There is no specific answer for any of these questions because you’re the one that has to answer them in relation to what you want to do with the truck. CT

The hardest part about the front end is guessing where the front wheel is going to go during full travel. We took an educated guess and placed the drop center on the upper control arm right where it bends. On wider wheels this is the point where the inner lip of the rim can rub. We marked this point on the ground.

The hardest part about the front end is guessing where the front wheel is going to go during full travel. We took an educated guess and placed the drop center on the upper control arm right where it bends. On wider wheels this is the point where the inner lip of the rim can rub. We marked this point on the ground.

This image illustrates what is called scrub radius.

Scrub radius is very important on the front wheels

because it affects handling and steering. Scrub

radius is the distance between the center of the tire

contact patch touching the ground while mounted

on the front hub at ride height and the imaginary

line passing thought the upper and lower ball joint

balls that intersect with the ground under the tire.

It is measured in positive or negative inches or

millimeters. Negative scrub radius is where the

contact patch center is outboard the virtual pivot

axis intersection with the ground. “0” is when they

coincide, and positive is when the contact patch

center is inboard the virtual pivot axis intersection. A

slight positive scrub radius is preferable for steering

feedback and reduction of tram lining and ridge

nibbling. It is required on front drive vehicles and

vehicles with ABS to prevent excessive steering pull.

A zero scrub vehicle has somewhat “numb” steering,

but braking and steering loads are equalized.

Negative scrub is common with wide front tires as it

is diffi cult to build a wheel and suspension that will

deliver this with a wide tire. Try to minimize scrub

as much as possible to prevent a vehicle that follows

every seam in the road and gives negative steering

feedback, in addition to braking instability and

excessive steering component wear.

This image illustrates what is called scrub radius.

Scrub radius is very important on the front wheels

because it affects handling and steering. Scrub

radius is the distance between the center of the tire

contact patch touching the ground while mounted

on the front hub at ride height and the imaginary

line passing thought the upper and lower ball joint

balls that intersect with the ground under the tire.

It is measured in positive or negative inches or

millimeters. Negative scrub radius is where the

contact patch center is outboard the virtual pivot

axis intersection with the ground. “0” is when they

coincide, and positive is when the contact patch

center is inboard the virtual pivot axis intersection. A

slight positive scrub radius is preferable for steering

feedback and reduction of tram lining and ridge

nibbling. It is required on front drive vehicles and

vehicles with ABS to prevent excessive steering pull.

A zero scrub vehicle has somewhat “numb” steering,

but braking and steering loads are equalized.

Negative scrub is common with wide front tires as it

is diffi cult to build a wheel and suspension that will

deliver this with a wide tire. Try to minimize scrub

as much as possible to prevent a vehicle that follows

every seam in the road and gives negative steering

feedback, in addition to braking instability and

excessive steering component wear.