The new 56 Series Extreme Bead lightweight wheel in action on Kelly Shryock's Modified.

The new 56 Series Extreme Bead lightweight wheel in action on Kelly Shryock's Modified.

Wheel technology is constantly improving. That, in turn, improves the safety of racing wheels. Like any other racing part, great improvement has taken place over the years to make the wheels more durable as well as offer more performance. Because of the failures brought on by using OEM wheels in racing applications, the need for specialized wheels sprang up. Today's racing hybrid wheels have evolved into products that have many innovations, which may go mostly unnoticed, but are there for a trained eye to see.

We wanted to get the latest on racing wheel technology directly from the people who manufacture racing wheels, so we asked a few of them some simple but pointed questions so we could learn more about today's wheel technology. Our panel consists of technical contacts at each of the four top circle track wheel companies. We received and included information from, in alphabetical order, Wayne Redmond of Aero Race Wheels, Rick Clement with Bart Wheels, Brian Gill of Bassett Racing Wheel, and Gregory Smith representing Weld Wheel Industries.

1. What market do you primarily service with your racing wheels?

The Bart Late Model wheel features a specially designed high-strength center for the application. The wheel is available in sizes ranging from 15x7 to 15x14. There are also standard and lightweight versions available.

The Bart Late Model wheel features a specially designed high-strength center for the application. The wheel is available in sizes ranging from 15x7 to 15x14. There are also standard and lightweight versions available.

AERO: We manufacture steel racing wheels used in competition in various forms of racing, from parking lot autocross, to short tracks, to the high banks of Daytona.

BART: We are a full-line manufacturer of wheels. The bulk of the products manufactured goes into the open-wheel Modified, Street Stock, and Pure Stock classes.

BASSETT: Bassett Racing Wheel serves the dirt and pavement circle track racing markets. Our most popular wheel sizes are 15x8, 15x10, 15x7, 13x7, 15x15, 15x14, and 15x9.5. The classes include IMCA dirt Modified, Stock Cars, Hobby Stocks, pavement Late Models, East Coast Modifieds, DIRT Sportsman Modifieds, Legends Cars, Mini-Stocks, USAR Pro Cup, NASCAR Nextel Cup Series, Busch Series, Craftsman Truck Series, and ARCA.

WELD: We offer forged aluminum racing wheels for most oval track racing applications, but Weld Racing caters to Sprint Cars (non-wing and winged), USAC Silver Crown, Midgets, Micros, dirt Late Models, DIRT big-block, and small-block Modifieds. Weld Racing also offers a steel NASCAR-approved wheel for Nextel Cup Series, Busch Series, and Craftsman Truck Series.

2. What areas of wheel construction are the most vital to endurance?

The Bart IMCA Modified wheel is available in 15x8 and all of the popular bolt patterns and backspaces. This wheel is offered in chrome, black, and silver powdercoat.

The Bart IMCA Modified wheel is available in 15x8 and all of the popular bolt patterns and backspaces. This wheel is offered in chrome, black, and silver powdercoat.

AERO: Several things factor into this, from the grade of material being used to thickness of the material and the placement of mass. Of course, the disc center is a very critical point because that is what holds the wheel onto the car. But the actual rim shell is also critical because material that is too light can allow the rim to collapse.

BART: I don't know that there is one particular area. Rim construction is vital for endurance, because a rim that is too thin or too light will fracture in the radii. Center construction is vital to endurance in two ways: lug nut retention keeps the wheel tight to the hub, and the design of the center itself allows for some flexing to occur.

BASSETT: Circle track race cars subject wheels to much greater loads than OEM or aftermarket street wheels were designed to handle, so it is important for racers to use a circle-track-specific wheel. The construction of a strong steel racing wheel begins with the raw material.

We use only HSLA formable steel purchased directly from nearby steel mills. Bassett's wheel centers utilize a deep-dish angle, a raised torque ring with coined lug nut seats, and specially designed vent holes with edges that are compressed to prevent cracking.

Bassett also produces its rim shells (the outer hoop portion of a wheel) in-house using a CNC spinning lathe for improved conformity and consistency, as well as lower weight. Spun-form rim shells also improve wheel strength by work hardening the steel.

WELD: The whole wheel is vital to endurance. From the construction of the wheel rim shell to the wheel center, each will play a vital role in the performance of the wheel. If the two don't work in sequence, then the wheel won't last.

3. What should a racer look for when choosing wheels related to a particular type of racing?

The Aero CT 56 Series wheel. These are popular in the Modified divisions

The Aero CT 56 Series wheel. These are popular in the Modified divisions

AERO: Quality, affordability, and a knowledgeable manufacturer that can help the racer choose the correct weight and design of wheel for the particular application.

BART: Don't be so concerned about weight. Pay more attention to construction. People like to talk about moment of inertia when it comes to wheels, but what racers forget is that they do not race on wheels, they race on tires. By adding a tire to the equation, it begins to zero out the effect of the weight of the wheel. Make sure the wheel has a good lug nut retention coining, and a strong torque ring to ensure proper wheel retention.

BASSETT: The racer needs to analyze the type of racing or series and decide what is most important. For example, a NASCAR Elite division or ASA Late Model team might want the lightest wheel on the market, while a weekly Street Stock racer might want to give up some weight in exchange for added wheel toughness.

We specialize in lightweight wheels that retain strength through precise placement of material in critical areas. It is important for racers and rule makers to remember that a well-designed, lightweight wheel will have a longer fatigue life than a poorly constructed heavyweight wheel. A well-designed, lightweight wheel acts much like a crumple zone on a car, absorbing crash impact and preserving other suspension and drivetrain components.

WELD: Look at a wheel's features and benefits of the wheel construction. Pay attention to the wheel material make-up, strength, trueness, weight, and safety.

4. What can a racer do with your wheels to make them less safe?

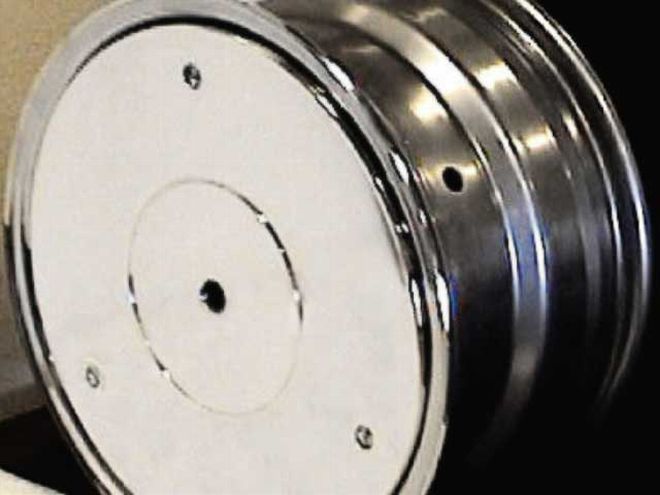

The Aero chrome dust cover can be attached to a dirt racing wheel to keep mud and dirt from getting onto the wheel and into brake area.

The Aero chrome dust cover can be attached to a dirt racing wheel to keep mud and dirt from getting onto the wheel and into brake area.

AERO: Hitting the wall! Misuse, grinding, drilling, and incorrect tire mounting or dismounting procedures will make a racing wheel unsafe. Running tires without enough air pressure and running a wheel that is too light for the particular application are two other ways to go wrong. Also, not having the lug nuts tight enough or overtightening the lug nuts are both unsafe practices.

BART: Drilling additional holes in the wheel for various reasons. These can become starting points for cracks that might migrate into critical areas, even if the original hole is located away from those areas.

BASSETT: The number-one issue is the use of an undersized hub hat or spacer plate. The racer should use a steel spacer plate with a minimum diameter of 7 inches.

The second issue is loose lug nuts. Always have a crewmember recheck the torque of your lug nuts before going on the track. We recommend 85 lb-ft of torque. Always use steel 1-inch oversize lug nuts with a 45-degree seat chamfer.

The third issue relates to inflating tires. We recommend that racers never exceed the tire manufacturer's max air pressure during inflation. It is also recommended that racers have a tire mounting professional mount the tires. The fourth issue is racers attempting to repair damaged wheels.

WELD: Many times, racers will try to lighten the wheel parts beyond the realm of the wheel's material makeup, thinking that they will have a lighter rotating mass. As a result, they risk part safety or part breakage. They also make the mistake of not checking out the parts after a hard wreck, thinking the wheels are OK if they roll straight.

5. Do racing wheels have a life span? If so, what life span should we safely expect for different types of racing?

The Bassett Cornering Fatigue Testing Apparatus simulates the force a racing wheel is subjected to while traveling through a corner. The test load varies based on the intended application (i.e., 2,500 ft-lb for a dirt Modified, 3,500 ft-lb for a Nextel Cup car).

The Bassett Cornering Fatigue Testing Apparatus simulates the force a racing wheel is subjected to while traveling through a corner. The test load varies based on the intended application (i.e., 2,500 ft-lb for a dirt Modified, 3,500 ft-lb for a Nextel Cup car).

AERO: They live well until they hit the wall. We are continually testing wheels with extreme loads on a corner fatigue machine and a rotary test machine. We test our wheels to failure points that are above and beyond the life expectancy of a wheel under normal racing conditions. Most wheels will probably crash way before their lifelines are up. We still see some wheels from 1996 in competition.

BART: Wheels are a working component of the race car, just like every other part. Under normal use, I would expect a one-year life span on most wheels.

BASSETT: As a stressed component on a race car, a steel racing wheel fatigues over time. Because the conditions of use vary so much, there is no way to determine how long a wheel will last. As a rule of thumb, pavement race cars are harder on wheels than dirt cars, and right-side wheels are subjected to higher loads than left-side wheels. So if you are a pavement racer at a steeply banked track, Bassett recommends rotating your left- and right-side wheels and replacing right-side wheels after two seasons of use.

WELD: A wheel's life depends on the racer. It depends on how hard the racer is on the equipment and how well the team keeps up on routine maintenance. Your better pro Sprint Car, dirt Late Model, and DIRT Modified teams use their wheels for the season, sell them, and then start off the new season with fresh equipment.

6. Can racing wheels be repaired by products that bend the rims back into shape?

The Weld Racing Wide 5 wheel is a popular choice for the W5 application. The Wide 5 XL exceeds wheel standards and specifications for all racing series and is available in most popular Late Model and DIRT Modified wheel application sizes.

The Weld Racing Wide 5 wheel is a popular choice for the W5 application. The Wide 5 XL exceeds wheel standards and specifications for all racing series and is available in most popular Late Model and DIRT Modified wheel application sizes.

AERO: To a certain extent, yes, but it is only a temporary fix. A lot of the success depends on the grade of material being used by the manufacturer. Some material may be very brittle and will crack when bent. We actually designed one of these tools and marketed it with confidence that the material in our wheels would withstand the use of this tool.

BART: My opinion is no. By stretching the material back into shape, the metal is fatigued in the radius of the material being bent back.

BASSETT: We do not recommend repairing bent wheels with tools. If the wheel's bead flange is bent so badly that it needs to be repaired in order to hold air, the wheel should be discarded. The reason Bassett opposes bending rim shells back into shape is that the act of bending the steel further stresses the metal, which can lead to fatigue cracks and failure.

Another major concern we have is that during tire mounting, a wheel with a distressed or damaged bead flange could fold over, causing the tire to blow off the wheel and severely injure or kill the person mounting the tire.

WELD: Yes, wheels can be repaired. It just depends on the material and the manufacturer's construction method. Most three-piece wheels can be replaced with an inner or outer rim shell or a new splined center to make the wheel true or useable again. A two-piece wheel commonly used on a dirt Late Model can be repaired, depending on the damage done and if that damage affects another part of the wheel.

7. How can the racer know when a wheel has been stressed or otherwise damaged?

Bassett's Inertia Advantage wheels are optimized for low moment of inertia by placing weight closer to the wheel's axis point. A lower moment of inertia results in more horsepower when measured at the tires. Bassett offers Inertia Advantage designs in sizes 15x8, 15x10, 15x9.5, and 13x7.

Bassett's Inertia Advantage wheels are optimized for low moment of inertia by placing weight closer to the wheel's axis point. A lower moment of inertia results in more horsepower when measured at the tires. Bassett offers Inertia Advantage designs in sizes 15x8, 15x10, 15x9.5, and 13x7.

AERO: Looking for cracks in the material or stress cracks in the paint finish is a way to detect damage. Check the stud holes for wear, and pay particular attention to the lug nut seat area. If the lug nut seat area is elongated or worn out of round, the wheel should be destroyed. Another key area is the torque ring on the backside of the wheel. There is an inner and outer torque ring on the backside of the wheel, and both of these areas should contact the hub surface.

BART: Check for cracks along the bolt pad. Dismount the tire and inspect the radii in the rim for any signs of cracking or fatigue. Stress will show in the form of cracked finish (paint) where the flexing is occurring.

BASSETT: This is exactly the reason we don't recommend racers attempt to repair damaged wheels--the racer will not be able to tell when a wheel has been stressed to the point of cracking. If a wheel has no visible signs of stress, but has been used for more than two seasons, the racer should check around the center-to-rim shell weld area for small fractures.

The other area to inspect is the lug nut seat area. If the lug nut seats on the torque ring show galling or no longer have a chamfer, the wheel should be replaced.

WELD: Following a routine maintenance program is one way of checking out the wheels after a wreck.

8. Some racing series require and/or allow pit stops to change tires. If the racers use adhesive to hold the lug nuts in place, does grinding the wheel stud holes to remove old glue weaken the wheel over time?

This multiple-piece wheel is used in Sprint Car applications. The Weld Magnum Spline wheel exceeds USAC wheel standards and specifications for all racing series and is available in most popular Sprint Car application sizes.

This multiple-piece wheel is used in Sprint Car applications. The Weld Magnum Spline wheel exceeds USAC wheel standards and specifications for all racing series and is available in most popular Sprint Car application sizes.

AERO: Each and every time the team takes a wire brush to the stud holes, they are removing wheel material. So the harder they scrub, the harder they are on the wheel. Thus, they are shortening the wheel's life span. The new trend is to glue the lug nuts along the top edge and not in the lug nut taper portion. But they still fire up the wire brush to clean them.

BART: Not if care is taken to ensure the minimal amount of grinding is done.

BASSETT: Yes, over time, the wheel lug nut seats will wear and, as we described before, the racer should inspect the seats every few races. If the lug nut seats show galling or the chamfer is gone, the wheel should be replaced.

WELD: Yes, grinding the wheel stud holes runs the risk of elongating them, which doesn't allow the wheel to spin true on the hub and quite possibly creates a vibration felt throughout the car.

9. Does wheel spacing off the hub affect the strength of the wheel and its life span?

AERO: Yes, depending on the spacer and how it is used. If proper steel spacers are used that encompass both the inner torque ring and the outer torque ring, there is less chance of damage. Spacers should be bolted to the hub surface. That way, there is no possible movement between the hub, spacer, and wheel.

Spacers with the proper diameter are another issue. A spacer with an od (outside diameter) that is too small will not encompass the outer torque ring of the wheel, and it will end up acting as a can opener. The same holds true for a spacer with an id (inside diameter) that is too large. So pay attention to see if your spacer covers the inner and outer torque rings of the wheel. Aluminum is not recommended for wheel spacers.

BART: The spacing itself affects the studs more than the wheels. However, care must be taken to ensure that the spacer is large enough in diameter to cover the entire back mounting surface of the wheel. A lot of times, racers will turn down the outside dimension of the spacer in an attempt to save weight, but often the spacer will not fit properly.

BASSETT: When the correct wheel spacer is used, it will not affect the life span of a wheel. Bassett recommends the spacer plate be steel, 7 inches in diameter, and a minimum of 116-inch thick. Avoid aluminum spacers or those smaller than 7 inches in diameter. If the amount of spacing exceeds 12-inch, it is safer (and lighter) to simply change the wheel to a different backspacing.

WELD: This depends on how the wheel is spaced off the hub. As long as the wheel and hub stay true to each other, fit flat against each other, and have enough lug nut engagement area, the strength or wheel life span are not questioned.

10. What tips can you give the average circle track racer that will help him/her maintain and avoid problems with wheels?

AERO: When in doubt, call the manufacturer and ask. Keep the lug nuts properly torqued. Make sure there is no foreign material on the hub face or wheel back when installing the wheel. Inspect your wheels before and after each outing.

BASSETT: Visually inspect the wheels each week during the race season. At the end of the season, take a wheel inventory and replace the wheels that have damaged bead flanges and worn lug nut seats.

When cleaning the wheels, use a mild detergent soap and gently wipe off the brake dust or dirt. Recheck your lug nut torque before each race and use caution when mounting tires--never exceed the tire manufacturer's maximum inflation pressure.

WELD: Following a routine maintenance program will keep you from DNFs and keep you on the track.

Conclusion

What We Have Learned Through this question and answer session, we have learned certain basic truths about wheel technology, maintenance, and safety. We know we must be aware of rim stress and fatigue. The majority find that repairing a bent rim is probably not a good idea.

Worn lug holes are a sign that the wheel needs to be replaced. We need to use wheel spacers of the proper size, and they need to be made of steel. Wheels have a life, just like other highly stressed parts on the race car, and need to be replaced after a period of use. Never seriously overinflate the tire on a wheel. Use just enough pressure to seat the bead and then lower the pressure to the starting pressures. If you need to stretch the tire for reduced stagger change, use the race pressures.

The bottom line is that if you follow recommended maintenance procedures, inspect the rims often, and replace bent or worn wheels, you will probably never have a wheel failure that could cost you a race.

Contact your favorite wheel manufacturer to learn more about their products and how they can fit your needs.