| Yellow Bumble Bee Version 2.0 - Honda B16 Tech Attack

| Yellow Bumble Bee Version 2.0 - Honda B16 Tech Attack

One of the happiest times of my life was driving my yellow bumble bee; the Integra you see here. Mind you it was my first real car, unless you consider the 1984 Civic DX I owned for six months before overheating it and destroying the engine. What can I say, I was young. The Integra and I have gone through many ups and downs, including a stint of destroying three engines in a six month period while on a hellacious boost bender.

But the one thing I remember most about the Acura was the joy I had driving the car when it was just naturally aspirated. It's ironic that working here at Turbo magazine you would think the best ride of my life would be in a turbocharged ride. But there is just something pure about driving an N/A-engined car that I can't explain. Sure a turbocharged engine with the same displacement might make two or three times more horsepower but it just not the same.

The sound generated from the Integra's 1.8-liter engine at full song was music to my ears. With the engine matched to the close-ratio B16A transmission I was in heaven. Of course the days of N/A were put aside when the need for more power led to forced induction. Prior to selling the car, the turbo kit was removed and sold off. The built B18A engine was switched out for a stock N/A B16A engine.

Well, the car has come full circle and the new owner has felt the same joys of driving the yellow bumble bee in N/A trim that I felt several years earlier. The new owner contests that with each new part that goes on the Acura the more fun he has driving it. The car might be yellow in color but it doesn't mean it is a coward and has proven itself against many competitors at the drag strip.

Month after month we inch toward our horsepower goal of 200-whp out of our B16A engine. With 181.30 horsepower under our belt we still need another 19 horsepower to reach our mark. Unfortunately, from previous battles with normally aspirated B-series engines we know trying to make that last 19 horsepower will be the hardest part. It would be pretty damn easy to make another 19 horsepower with a little squirt of nitrous or add a low-pressure turbo system but that would be the easy way out. And we have already proved the car is capable of generating 221.09 horsepower on nitrous.

The only way we are going to be able to make that last 19 horsepower is by increasing the displacement of the engine. The easiest way to increase the displacement in the B-series engine is to increase the bore of the cylinders from 81 mm to 84 or 85 mm. However, to do so would require resleeving the block with larger sleeves. That can drive up the cost. Also, finding a reputable machine shop to do such a major install is limited. Knowing how extremely popular the B16A engine is and with enthusiasts demanding them, affordable stroker kits for the B16A have been available for some time.

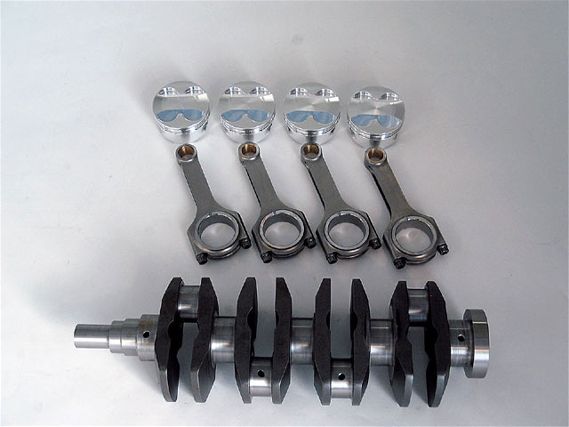

Peak Performance now offers a 1.9-liter stroker kit for B16A engines utilizing the factory sleeves. The Peak Performance stroker kit comes with new, forged CP pistons, Peak Performance connecting rods and a Peak Performance crank. The CP pistons can be ordered in different compression ratios; we chose 11.2:1 compression pistons. Raising the compression ratio any higher would more than likely require the use of 100-octane fuel. Since the car is still a daily driver we wanted to stick to pump gas. The CP slugs are .020-inch larger, increasing the bore diameter to 81.5 mm. Custom dry lube on the piston skirts reduces drag against the cylinder walls for increased performance at high rpms.

The majority of the increased displacement comes by way of a longer-stroke crankshaft. The factory B16A crank features a 77.4 mm stroke while the Peak Performance crank stroke is 89.0 mm. The longer stroke and increased bore pushes the displacement of the B16A engine to 1856cc.

The new longer-stroke crankshaft requires custom-length connecting rods. Stronger rods are not only essential in forced-induction engines but also any high-rpm N/A powerplant. The Peak Performance rods are engineered from 300M steel and are custom balanced to work with the pistons and crank. The H-beam connecting rods are designed to be able to handle the high-rpm operations of the B16A engine and still be fairly lightweight.

With all the parts in hand the pistons and block were sent to Benson's Automotive Machine in Santa Ana, Calif., for boring and machining. Once the machine work is completed we will be sending all the parts onto Omni Power USA for complete blueprinting and assembly.

We are still contemplating using the GS-R head from the last installment or a B16A head with the bottom-end. The smaller combustion chambers of the GS-R head will push us pass the 11.2:1 compression ratio we hope to run. With the GS-R head we will be running a compression ratio of closer to 11.7:1 so pump gas might be out of the question. We'll be sure to let you know what direction we take in a future installment. Stay tuned.