It is a known fact that a person's pupils dilate slightly when viewing something pleasant to the eyes. Well, gaze upon these numbers—a 421ci Pontiac with Tri-Power carburetion.

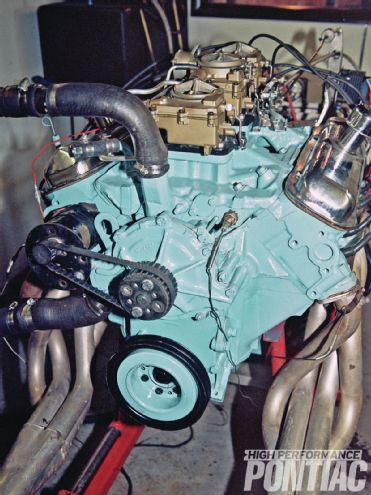

Here’s the fresh 421 on the dyno. More about what it achieved will be published next month.

Here’s the fresh 421 on the dyno. More about what it achieved will be published next month.

Wide-eyed yet? We are.

Here is another number to ponder: 370 hp. That's the factory rating of the legendary 421 H.O. Tri-Power equipped Pontiac hot rod—a stout piece by anyone's standards.

Ever wonder what it would take to increase that number by 100? Jim Taylor, well-known Pontiac engine builder, had that question on his bucket list for years. Jim told HPP, "Since I was a young man in the '60s, I always thought how great it would be to find a true 100hp in a legendary 421 Tri-Power setup that retained its iron heads and intake. I don't know if it can be done, but I'm going to try." HPP decided to follow this exciting exercise; we show you the highlights in this two-part primer.

True Pontiac engines were designed and built in Detroit—not on a computer, but often by GI-bill-educated engineers who grew up working with their hands and now had a slide rule in their pocket instead of a greasy rag. These guys lived by mathematics since every function of an engine that converts chemical to mechanical energy can be assigned a number. Math, not gasoline, makes horsepower under the hood of a Pontiac. Jim Taylor knows this, so he took a mathematical engineering-style approach to finding 100 hp in a relatively optimized engine.

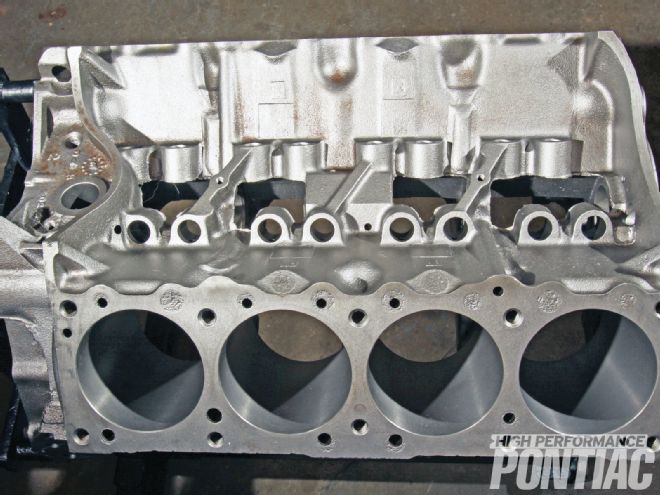

The block used for this build is an original ’64 casting #157, which is a transitional design in regard to its oiling system. Though it was built with newer style pushrod oiling, the provisions for the older design rocker-stud oiling system remain.

The block used for this build is an original ’64 casting #157, which is a transitional design in regard to its oiling system. Though it was built with newer style pushrod oiling, the provisions for the older design rocker-stud oiling system remain.

It's well documented that an internal combustion engine is nothing more than an air pump. Greater throughput mixed with the proper amount of fuel and ignited at the ideal time for the flame to expand against the piston will result in more power. Thus, the quest to find 100 hp in a 421 started on the flow bench, before a wrench or machine tool touched any part of the 49-year-old engine. Not where most enthusiasts go first.

Using an equation the author has provided in HPP many times—most recently with The Mule engine series—it was revealed that around 228.6-cfm flow though the intake port of the cylinder head is required to produce the desired 470 hp.

For those who may not be familiar with the equation, here it is again:

Required airflow at 28 in/H2O = HP/ # of cylinders/0.257

To determine horsepower from airflow, invert the equation:

HP = flow at 28 in/H2O x 0.257 x # of cylinders

Though airflow is paramount in making power, there are other aspects of the engine that are just as important. Where else will the extra 100 horses come from?

Starting at the bottom, Jim will employ lighter and stronger parts in the reciprocating assembly, as evidenced by the choice of Howards billet rods and forged Icon pistons. The rod weighs 751 grams versus the stock rod at 958 grams. The piston weighs 630 grams with the pin versus the stock piston and pin weight of 790 grams. Reductions in reciprocating weight free up horsepower.

For a few more ponies through better oil control, a factory full-length windage tray will be added, since Pontiac didn't use one on this engine originally. Cam choice is always extremely important, and Jim decided to go with an aggressive Crower mechanical flat-tappet stick with 247/252-degrees duration at 0.050 and 0.515/0.525 lift (0.495/0.505 with 0.020 lash) with 1.6:1 rockers. Crower identifies this cam as a Level 4, which means it provides strong midrange and top-end power for heavily modified engines.

The company says engines running this cam benefit from headers, cylinder-head port work, a large-cfm carb, and an ignition upgrade. It requires a compression ratio of at least 10.25:1. By comparison, the factory 421 H.O. cam specs out at 215/225-degrees duration at 0.050 and has just 0.407/0.407 lift with the factory 1.50:1 rockers.

Regarding Crower's upgrade suggestions for its camshaft, Jim pretty much has it covered. He says the Tri-Power setup modified with the addition of the larger '66 center carb will flow 1,050 cfm. A set of Hooker Super Comp headers will be used on the dyno, and Jim is porting the stock heads to increase intake-port flow by 30 cfm. He thinks the stock exhaust flow of 180 cfm will suffice for this build. The compression ratio will be 10.6:1. While all this sounds great, remember the engine will have to retain the small 1.92-inch intake valve because chamber space is too tight for larger ones.

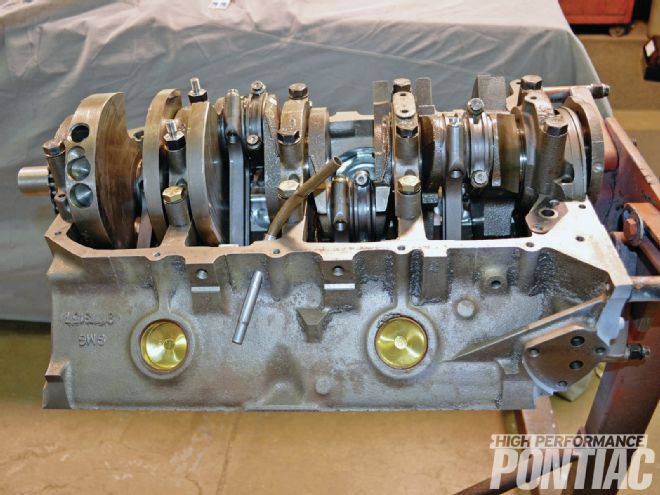

8. The ‘64 block features a reinforced bulkhead, a design left over from the NASCAR- and NHRA-specification SD style. Here the bottom end is completed and awaiting the installation of the oil pump and the addition of a windage tray.

8. The ‘64 block features a reinforced bulkhead, a design left over from the NASCAR- and NHRA-specification SD style. Here the bottom end is completed and awaiting the installation of the oil pump and the addition of a windage tray.

Along with proper parts selection, accurate machining and assembly are also important. Metallurgy of the critical parts is an area often overlooked, but not by Jim Taylor. Over the years he has amassed a library of data from investing in metallurgical testing with a well-respected laboratory. He wanted to confirm his parts are up to the task of holding the cylinder pressure that creates horsepower. Simply put, what good is the power if the engine does not last?

The engine build will be discussed in two parts. This installment includes the assembly and parts selection up to the long-block. Next time we will cover the induction system and the dyno testing to see if Jim meets his goal.

Since the story of this 421 is better told in pictures, follow along as we take you on this exciting journey!

Engine Displacement: 432 ci

Horsepower: See Part 2

Torque: See Part 2

Bore/Stroke: 4.150/4.00-in

Block/Crank combo: '64 four-bolt 421 / '64 OE 4.00-in stroke

Bore/Stroke ratio: 1.04:1

Rod/Stroke ratio: 1.65:1

BOTTOM END

Block description: '64 421ci #157

Preparation: Cook, bead blast, magnaflux, bore, true decks, align bore

Deck Height: 10.215-in

Crank: Original '64 421

Preparation: Magnaflux, check for equal stroke and index, grind, polish 0.010-in

Balancer: Original PMD rebuilt by Damper Doctor

Rods: Howard's billet 4340 certified steel, stock 6.625-in, floating pins

Preparation: Weigh, soap-and-water wash

Bearings: Sealed-Power mains and rods, cam Dura-Bond

Preparation: Install in rod, torque, measure ID

Pistons: Icon PN IC892 application 428 +0.030-in with 10cc dish

Preparation: Wash after balance for assembly

Piston-to-deck height: 0.009-in

Piston pins: Icon, SAE 1016 to 1022

Method used to retain pins in pistons: . Spiral clip

Rings: LPC (Liberty Performance Components) premium moly, standard tension

Preparation: File-fit for end gap if needed, wash

Rod bolts or studs/head bolts or studs: ARP cap screw supplied in Howard's rods / PMD

OILING SYSTEM

Windage tray: Original PMD '70 455, fabricate fit, no bosses at cap #2

Oil pan: 8-quart with extended pick-up, fabricated retention clamp

Oil pump: . . Melling PN M54D with 60 psi spring, made 70 psi at 6,000 rpm with 30W oil

Preparation: Disassemble, check ball seat for width, spring tension, plate clearance

HEADS

Casting number: 97770716, '64 date

Chamber: Closed, special to PMD, 70 cc

Head mods: Port, cook, magnaflux, glass bead, convert to screw-in studs

Maximum flow at 28 inches of water

Intake: 218 cfm at 0.500-in

Exhaust: 180 cfm at 0.500-in

Compression Ratio: 10.6:1 effective

Valves: Competition Products stainless steel, 1.92 /1.66-in

Angles used in valve job: 30-deg intake, 45-deg exhaust seat, width 0.040-in intake, 0.060-in exhaust

Mods: Intake port match, valve bowl blend, improved short-turn radius

Retainers: Crower steel

Keepers: Comp Cams race locks

Valve guides: K-Line, liners

Valve seals: U.S. Seal

Rocker studs: ARP special 3⁄4-in bottom

Rocker arms: Crower roller, 1.6:1

Pushrods: LPC chrome moly

Diameter: 5⁄16-in

Length: 8.750-in

CAM

Brand: Crower PN 60311, solid

Duration at .050: 247/252-deg

Lift: 0.515/0.525 with 1.6:1 rockers

Centerline: 110-deg

Lobe separation angle: 112-deg

Installed position: 110-deg

Lifters: Crower solid with EDM oil hole (0.024 inch)

Valvesprings: Crower, dual no damper

Seat pressure: 110 pounds at 1.600-in

Open pressure: 282 pounds at 1.100-in

Timing chain: LPC, double roller

INDUCTION

Carb: (3) Rochester two-barrels PMD

Size cfm: Total flow, 1,050 cfm

Mods: Built to factory specifications/ adapt '64 choke to '66 center carburetor

Jets, Primary: Center #64 adjust power valvespring for 12 Hg at 1,000 rpm

Secondary: Front and rear #70

Fuel pump: Will use 110-gph Carter

Fuel line size: 3⁄8-inch, 5⁄16-inch to carburetor

Intake manifold: Original '64 PMD tri-power

Mods: Flow-test indicated '66 center carburetor would be required to improve total cfm, adapter made to fit '66 center carburetor

IGNITION

Distributor: '61 Delco cast-iron with direct oiling

Coil: GM

Wires: NAPA Belden 7 mm

Total Timing: 36-deg BTDC

Initial advance: 18-deg

Mechanical advance: 36-deg at 3,200 rpm

Vacuum advance: Not used

EXHAUST

Headers: Hooker Super Comp (for dyno test)

Primary tube diameter: 1.75-in

Primary tube length: approximately 31.00 inches

Collector size: 3.00-in

GASKETS

Brand: Fel-Pro head and intake/ SCE pan and timing cover

Along with proper parts selection, accurate machining and assembly are also important

Math, not gasoline, makes horsepower under the hood of a Pontiac