Welding 101 - Tech

Welding 101 - Tech

I remember when I first picked up a welder and started playing with it. It was just a simple MIG welder, but that moment changed my life forever. Although I had no clue of what I was doing, eventually I was able to create an ugly but functional bead. As time passed, my skills improved. With a simple MIG welder, I was now able to fabricate anything from brackets to custom motor mounts for engine swaps. Eventually I got to the point where my MIG welder just wasn’t enough.

|

Welding 101 - Tech

|

Welding 101 - Tech

I wanted to get into fabricating parts with stainless steel and aluminum. Although a MIG welder is capable of welding these metals,

I knew that the best tool for the job would be a TIG welder. So, I enrolled in a TIG welding class at a local community college in hopes of learning a new skill. Within a few months, I was laying down some decent beads with a TIG. Taking that class has been one of the best things I’ve done for myself and my career.

I recently heard about Miller Electric’s new Diversion 165 TIG Welder. What’s amazing about this unit is how it was designed with the entry-level home fabricator in mind. Using inverter technology, it’s not only portable, but it has a low primary amperage draw, making it suitable for home use. All that’s required to run this machine is a 230V/25 amp circuit. If your garage had an electric dryer in it, you’re probably good to go. If not, most homes can be wired for this type of setup.

Instead of teaching you my bad habits, I contacted the experts at Miller Electric to see if they could help out with this month’s tool section. They quickly responded with a great beginner’s tech article, showing the basics of using this entry level TIG Welder. I’ll have to warn you that TIG welding is not an easy skill to learn and the process takes time. However, if you’re committed to learning how to do it, it’ll open a lot of doors for you down the road. — Gary Narusawa

Parts List

MSRP

Hookup

Miller Diversion® 165 AC/DC TIG Welder$1,617$1,350

TOTAL $1,617 $1,350

Beginning Welders: Tune Into Tig

Tungsten Inert Gas (TIG) welding has been around since the ‘40s, and until now had the rap of being too expensive or complex for most personal users. Achieving a weld with the “stacked-dime” appearance was only possible to professionals using professional equipment. That’s recently changed, however. If you are familiar with MIG, Stick or oxy-fuel welding, stepping up to TIG has never been easier or more affordable and will allow you to fabricate or repair aluminum oil pans, stainless exhaust systems, rollcages, suspension components, etc. The introduction of an affordable, easy-to-use TIG welder and a few simple hints can help you TIG-weld like a pro.

About TIG

TIG uses a non-consumable tungsten electrode to produce temperatures up to 35,000°F, yet allows the heat to be precisely controlled. An inert gas (usually argon) protects the weld from air contamination. If filler metal is required to make the weld, it can be added manually in the same manner as in oxy-acetylene welding.

Out of all the common welding processes, TIG welding offers the most controlled arc. It’s a clean process that leaves no slag, sparks, spatter, smoke or fumes.

The big advantage to owning a TIG welder, is the ability to weld almost any metal, including steel, stainless, titanium, chrome-moly, aluminum, copper, brass and bronze. Cast iron is the only metal not typically suitable for TIG welding. Because of the properties of cast iron, TIG welding this material isn’t typically done. However, in many cases (like cast iron head repair), it is really the only option and can be done successfully if the proper procedure is followed.

TIG Machines

To handle the variety of jobs encountered when working on cars and around the home, select a TIG welder with good high and low amperage ranges and AC/DC output capabilities (you need both AC and DC output if you want to weld-on steel and aluminum).

|

Welding 101 - Tech

|

Welding 101 - Tech

This past October, Miller introduced the Diversion®165, a new AC/DC TIG welder designed around simplicity and ease-of-use. More importantly, it was priced and developed specifically for the average guy working out of a home shop or garage. The goal was to eliminate the hard work from the setup and learning process.

Recognizing that newbies to TIG were often intimidated by “a control panel that resembled an airplane cockpit,” the Diversion® 165 features just two controls—one for heat input and one for selecting the metal type. It connects to 230V power for a welding range of 10-to 165-amps for both the AC and DC welding outputs. Included in the box is a TIG Welding for Dummies book, setup & operation DVD and a blueprint for welding a shop cart/cylinder rack.

Before we get into the how-to, let’s discuss what you need to get it all setup.

TIG Accessories

| A foot pedal control operates much like an auto’s gas pedal; the more you depress it, the more amperage flows. Another type of control – one that affords greater mobility– is a fingertip control, which is mounted on or built into the torch.

| A foot pedal control operates much like an auto’s gas pedal; the more you depress it, the more amperage flows. Another type of control – one that affords greater mobility– is a fingertip control, which is mounted on or built into the torch.

In addition to a bottle of argon, gas regulator, and hose, you’ll need a foot pedal or a fingertip control for the TIG torch. (The Diversion comes with a fingertip control). These controls allow you to control the amperage and contactor, as you weld. The contactor keeps the torch electrically cold until energized, as well as starts and stops the gas flow to the torch.

|

If most of your work is done on a bench a foot control may be sufficient. If, however, you weld under the car or in awkward positions that keep your feet occupied, go with a fingertip control.

|

If most of your work is done on a bench a foot control may be sufficient. If, however, you weld under the car or in awkward positions that keep your feet occupied, go with a fingertip control.

For most garage-related work, an air-cooled torch (where the argon shielding gas cools the torch) rated at 150 amps will be sufficient. It will also be smaller and easier to maneuver in tight spaces.

Before You Weld

The following suggestions address the basic areas of TIG welding setup; however, there is no substitute for carefully reading the operator’s manual, watching instructional videos and following safety precautions (e.g., wearing long-sleeve protective clothing, gloves, safety glasses and a welding helmet).

|

Welding 101 - Tech

|

Welding 101 - Tech

With that said, here are three quick tips for setting up.

1. Select and prepare the right sized tungsten - A 3/32-in., 2%, ceriated tungsten is a good all-around choice for aluminum, steel and stainless steel. | Welding 101 - Tech

3. Clean the weld area AND filler rod – Use a dedicated wire brush to help ensure a high-quality weld by cleaning oxides, paint, rust, shop dirt and other contaminants from the weld area. An abrasive pad should be used to clean the filler material as well.

Making a Good TIG Weld

The good news is if you melt the base metal and get the filler rod into the weld puddle, you’re most likely going to make a good weld. The bad news is that learning to make pretty weld beads, as well as coordinating your hands, feet and eyes, takes patience and practice. When you become more proficient, however, the results are very satisfying.

| 01 Practice welding on scrap - don’t try to add filler rod just yet. Flip the polarity switch on the welder to the DC setting (labeled “steel, stainless, chromoly” on the Diversion® 165) and turn on the welder.

| 01 Practice welding on scrap - don’t try to add filler rod just yet. Flip the polarity switch on the welder to the DC setting (labeled “steel, stainless, chromoly” on the Diversion® 165) and turn on the welder.

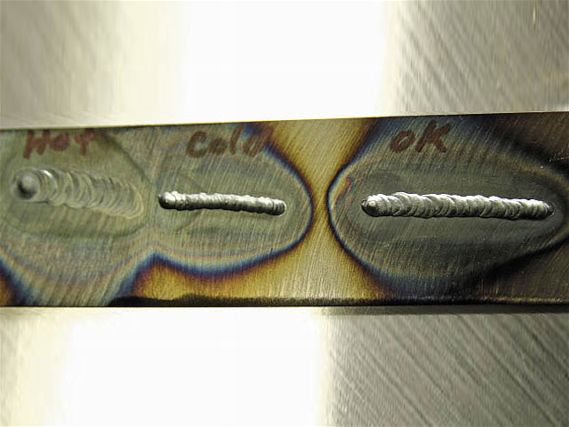

| 07 Practice your welds. Sometimes a slight adjustment to your amperage or travel speed can make all the difference between a weld that is too hot (far left), too cold (middle), and one that is just right (far right).

| 07 Practice your welds. Sometimes a slight adjustment to your amperage or travel speed can make all the difference between a weld that is too hot (far left), too cold (middle), and one that is just right (far right).

Aluminum

Examples

Thirsty for More?

Information for this article was sourced from Miller publications available to the reader. Miller’s 90-page Gas Tungsten Arc Welding handbook, provides a comprehensive, yet easy-to-read, explanation of the TIG process. It contains detailed instructions on how to setup TIG equipment, TIG welding techniques, filler metals, tungsten types, safety and troubleshooting. Cost is $15. To order, call 414.751.2120. Ask for publication #170 555, Gas Tungsten Arc Welding.