Send us your tech questions to: [email protected]

Manifold Science

Q This is more of a theory question for you guys. What's better on a high-revving, 1.6L engine: an intake manifold with short and wide runners or long and narrow ones? And how much does plenum size really matter?

Caesar W.

Trenton, NJ

A Smaller, high-RPM engines like yours generally respond well to intake manifolds with short, relatively wide runners, but you probably want to know why. Runner length determines exactly how much air will enter the cylinders when the intake valves open. Sort of like how a camshaft dictates an engine's power curve, so does the length of the intake manifold's runners. The key to figuring out how long exactly those runners should be lies in determining how much time it'll take the intake charge to bounce back and forth within a particular runner and ultimately arrive back at the valves as they begin to open. This is, as you'd expect, not exactly easy to figure out. One thing's for certain, though: since the intake valves open more frequently and faster on high-RPM engines, the distance that wave of air has got to travel must be reduced. As it turns out, the opposite is true for low-RPM engines, which are better suited to longer runners. With all of that said, ideal runner lengths can still vary significantly between two engines of equal target engine speeds if other variables, such as displacement, change. The confusion doesn't end there, either. The shape of the runners is just as important. The intake air charge has got to reach a high velocity in order to make it to the combustion chamber and actually ignite. Big runners can slow down the air stream, and although smaller, restricted runners can speed it up, they can sacrifice the amount of air allowed in. A compromise has got to be made, which generally lends itself toward the small side but with a caveat: the runners generally start big but taper down in diameter as the air gets closer to the cylinder head. All of this helps promote an acceptable air speed without sacrificing volume. Perhaps more obviously, though, each runner should also feature equal lengths and diameters. This allows each cylinder to receive the same amount of airflow at the same point during the intake valve cycle, which leads to equal combustion within each cylinder. And about those plenums—an intake manifold plenum is really just a reservoir. Air enters through the throttle body and takes a break inside the plenum just before entering its individual runners. When any individual cylinder requires more air it's simply pulled from the plenum. Generally speaking, smaller plenums allow for quicker, low-end torque production at the expensive of top-end horsepower while larger plenums lend themselves better to what it is you're after—high-RPM power.

Curbing Oil Temps

Q What do you guys know about oil coolers? I've got a turbo LS-VTEC setup in my Integra, which doesn't have one. I know that the GS-R engine comes with one so I was wondering that since I've now got the VTEC head and the turbo kit if I should get one. Also, would you guys recommend the OEM GS-R one or is an aftermarket oil cooler better?

Jeremy

San Antonio, NM

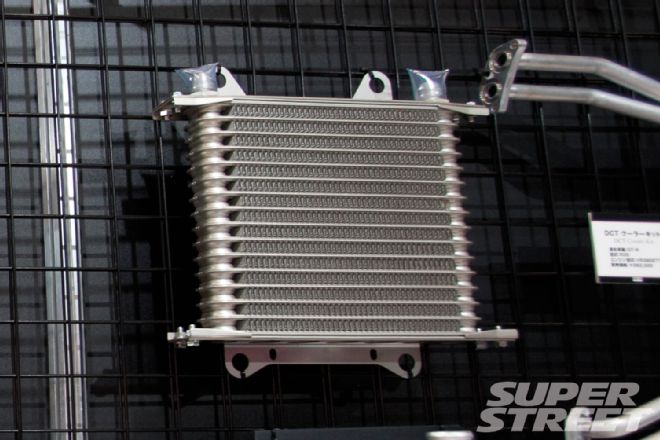

A Honda supplied the Integra GS-R with an oil cooler not so much because it needed it, but arguably to justify its higher cost when compared to other, less-expensive DOHC VTEC engines. It was one of many refinements that made just about everyone okay with the model's steeper price. Adding a turbocharger to the equation changes everything, though. Here, all sorts of additional heat comes into play, which can break down oil quicker than normal, decreasing its viscosity and lubricating capabilities. Your B18C engine will stay happy so long as its oil doesn't get any hotter than about 200˚ F. Unfortunately, that turbocharger, which pushes 1,200˚+ F exhaust gases around itself, can heat engine oil far beyond that. All of this is very bad news for engine bearings, piston rings and just about anything else underneath your valve cover. Retrofitting the factory GS-R oil cooler to your LS-VTEC isn't hard. You'll need the appropriate water distribution pipe, fittings, hoses, as well as the cooler itself to make it all happen, and with the right parts, it'll bolt on like it was meant to be there. If your power goals are modest—some place on the slow side of 500hp—then such an oil cooler will do. Here, the engine's coolant mixture flows around the oil filter housing, cooling the oil stream that passes through it. When coolant temperatures are high, though, so are oil temperatures. For higher-horsepower engines, an externally-mounted, air-fed oil cooler is almost always better. Much like an intercooler or radiator, air passes through the cooler's fins, resulting in a temperature drop within its housing. Air-fed oil coolers can typically reduce oil temperatures more than coolant-based ones since they remain independent from whatever's happening within the engine. To work best, though, the vehicle must be moving, and the cooler must be mounted someplace within the air stream. Air-fed oil coolers are typically more complicated to install, generally requiring durable, steel-braided hose and a series of AN fittings and adapters to tap into the engine's oil stream, which generally takes place near the oil filter by means of an external housing.

Valvetrain Disturbance

Q I'm noticing a lot of noise coming from the valvetrain of my 2003 Sentra SE-R Spec V. At first I thought it might need a valve adjustment but my mechanic says that its valve lash isn't adjustable and that's probably not it. What do you guys think it could be? Should I do a valve adjustment anyway?

Jeron

Chandler, AZ

A Chances are, it isn't the valves. Unlike other engines that have adjustable valve lash, your engine's valves don't need any sort of adjusting unless something's really wrong. Even then, it's no simple procedure. Instead of an adjuster screw that's either loosened or tightened to increase or decrease valve lash, here, a series of shims must be added or taken away to yield the appropriate clearance. It's a procedure that Nissan doesn't even consider standard maintenance, which means your mechanic's mostly right. Before considering any of that, though, check the following things: Be sure that your engine oil level is sufficient. A low oil level can lead to all sorts of suspicious noises from the valvetrain and is the most likely cause of what you're experiencing. An exhaust manifold leak, detonation or bad clutch release bearing can also be to blame. Examine the exhaust manifold for small cracks or leaks near its flanges and rule out detonation by determining whether or not the noise gets worse when subjecting the engine to additional load, like when climbing a steep hill. Finally, see if the noise subsides when stepping on the clutch pedal; if it does, see if that mechanic of yours has got time to replace your clutch release bearing.