|

| They look harmless enough, but cams are some of the most complicated parts of your engine. In simple terms, cams are long, cylindrical-shaped shafts containing several irregular-shaped lobes that convert rotary motion into reciprocating motion. They're driven by a belt or a chain, which links directly to the crank by a pulley. When spun (rotary motion), their lobes impart their eccentric shapes onto their corresponding rocker arm pads. Rocker arms actuate the cylinder head's valves (reciprocating motion) in an orchestrated fashion, relative to engine speed and synchronize with the engine's piston movement at precisely the right time. Although, an engine's valvetrain is made up of all sorts of components, only the cams determine when the valves open, for how long, and when they'll close. As a result, an engine's cams dictate its power curve and at what point in the RPM range the engine will produce maximum horsepower and torque. It all sounds simple enough, but cams are probably the most misunderstood part of the modern-day four-stroke engine.

Four-Stroke Basics

Speaking of four-stroke engines, you've really got to understand all of that before moving on. The 720-degree four-part cycle begins with the intake stroke where air and fuel are shoved into the cylinder through its open intake valves. During the compression stroke, the intake and exhaust valves start off closed as the piston begins to rise. Once the piston reaches the top of its bore a spark ignites, beginning the power stroke. Next, the explosion of air and fuel pushes the piston back down its bore. Once it reaches the bottom of the cylinder the exhaust valves open. Exhaust gases are then forced out as the piston rises again, completing the exhaust stroke. In the real world, though, the precise beginning and end of each cycle is pretty hazy because of cam profiles and all sorts of complicated physical and chemical constraints. Smarty-pants physics also tells us that poppet valves can't instantly open and close, so instead of 180-degree increments, an engine's valves typically remain open far longer to introduce enough air and release enough fumes.

|

| Lift

To understand cams, you've got to grasp at least these two things: lift and duration. Lift is the maximum distance a valve opens away from its seat and is usually represented in inches or millimeters. Imagine a room full of people trying to exit through a single doorway. They can open the door wider (lift) or leave it open longer (duration). Either way, more people are gonna get through. To understand why you should care about lift, you've also got to understand the relationship the valves share with the cylinder head. You know that you've got to have valves for the engine's cyclical process, but each valve's head (which is necessary for sealing against the valve seat) restricts airflow and must be moved as far away from its seat as practical to allow air to pass by. Increasing lift introduces more air and fuel into the combustion chamber and increases the rate at which exhaust gases may exit. Generally speaking, adding lift results in more power. However, the valves should also open and close as quickly as possible without causing valve float or damaged valve seats due to excessive impact.

|

| Despite the increased airflow that's associated with adding lift, some engines may not respond well to it at all. Most Earth-loving engines are designed so that more lift doesn't translate into an increase in usable airflow. Other engines may have piston-to-valve clearance issues where added lift can possibly result in see-through pistons, funny-shaped valves or both. Still, other engines might be equipped with valve springs that can't withstand increased valve movement. In other cases, the rest of the engine may not be optimized to do anything with that extra airflow. In other words, adding a high-lift cam to an otherwise stock engine will probably hurt more than help.

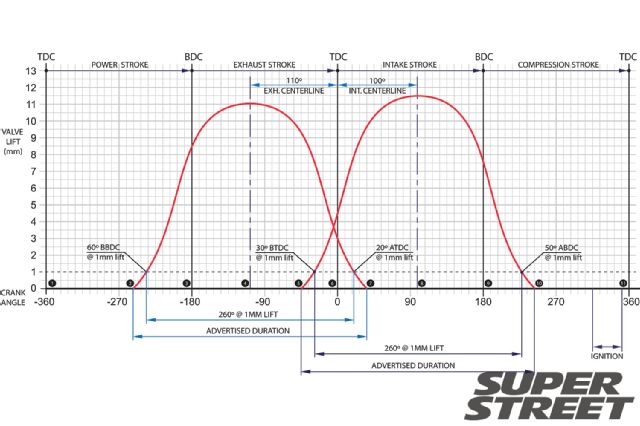

Duration

Increasing lift is an effective method for introducing more air into the cylinders, but holding the valves open longer (more degrees of crankshaft rotation) does something similar. Unlike lift, duration is measured in degrees of crankshaft rotation; it's the segment of the cycle that a particular valve is held open. You can't quantify duration in units of time, though, since at lower engine speeds the valves stay open longer than at higher engines speeds, despite equal durations. It makes sense then that adding duration holds the valves open longer—at any engine speed.

Like lift, increasing duration can also result in additional airflow and potentially more power. And like lift, adding duration will only add power to an extent. This, of course, will vary depending upon the engine. As duration increases, and the amount of time the intake and exhaust valves remain open increases, so do the chances that the intake charge may become contaminated with exhaust gases. Intake dilution happens when exhaust gases merge with the intake charge. In some cases, a portion of the intake charge can exit through the exhaust valves as well. This almost always results in poor idle and decreased performance at lower engine speeds. At higher engine speeds, when duration is the same but the actual time that the valves are opened decreases, performance generally increases. Engines featuring long-duration cams can usually be identified by a rough and lumpy idle, which, for a race car, usually isn't all that bad.

Ramp

Lift and duration are independent values but still complement one another. Together they result in a cam's profile, otherwise referred to as its rate of lift or ramp. Imagine a hill where its peak represents lift, the distance from the base of the hill on one side to the base of the hill on the other side represents duration, and the curvature of its slope is its ramp. If lift increases but duration remains constant, the hill gets steeper. If duration increases but lift doesn't, the descent and ascent become more gradual. Too steep of a ramp can result in all sorts of bad things like valve float and valve seat damage. Excessive cam wear is another indicator of too aggressive of a profile. On the intake side, a steep closing ramp is less of an issue, though, since cooler intake charges help ensure proper seating, but the exhaust side is different. Here, high temperatures within the exhaust ports and around the valves make the seats and valves more susceptible to damage. As far as opening profiles are concerned, a number of factors, including valvetrain weight, will determine an acceptable angle. Generally, an angle that starts out smooth and conservative and works its way up to an aggressive profile will impact valvetrain minimally.

Centerline

A cam's centerline is the fixed point on its lobe that occurs exactly halfway between when the valve opens and when it closes. Locating a cam's centerline isn't as easy as it sounds, though, since peak lift doesn't last for just a single degree of crank rotation. All you've got to do is look at the shape of a cam lobe to see how difficult pinpointing its centerline can be. Cam degreeing is a process that involves locating a cam's centerline and positioning it so that it occurs-in crankshaft degrees-exactly where the cam manufacturer says it should. If you've ever played with adjustable cam gears, then you've essentially done something similar, albeit somewhat arbitrary.

|

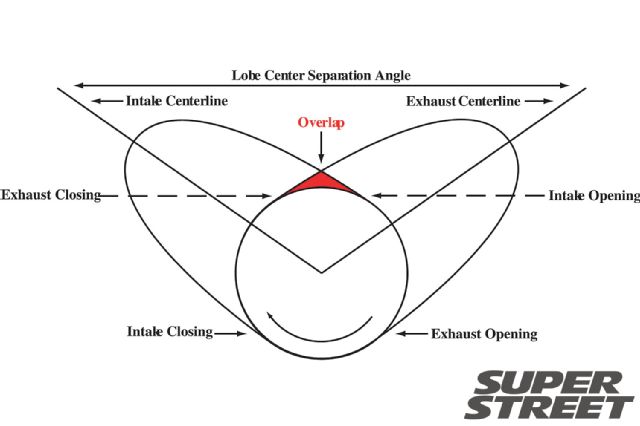

| Overlap and Valve Timing

The point at which both the intake and exhaust valves are opened simultaneously is known as overlap. Overlap generally occurs for a short period of time—when the intake valves are opening, the exhaust valves are closing, and the cylinder's piston is at TDC. Overlap might seem counterintuitive but the process helps draw exhaust gases out of the combustion chamber more efficiently. Also known as scavenging, the process can potentially increase horsepower by allowing for a more efficient cylinder fill by evacuating unusable gases more quickly. Too much overlap isn't always a good thing, though, and can draw the intake charge right into the exhaust, wasting both air and fuel.

|

| Lobe Separation Angle

A cam's lobe separation angle is the angle measured in crankshaft degrees between its intake lobe centerline and its exhaust lobe centerline. Dual-overhead-cam lobe separation angles can be manipulated with adjustable cam gears. This, combined with lift and duration values, will determine how much overlap there is. Cam degreeing not only locates the correct centerline but also allows the lobe separation angle to be realigned for optimum performance. Although trial and error on the dyno can lead to an ideal lobe separation angle, the risk of funny business between pistons and valves is greater and the process can take significantly longer.

|

| SOHC vs. DOHC

The shortcomings of the single-overhead cam are important, albeit obvious: it's simply impossible to adjust valve overlap here without grinding an entirely new cam. This is where dual-overhead cams shine. Here, overlap can be increased or decreased by independently controlling when the intake or exhaust valves open and close. Best of all, you need only a set of adjustable cam gears to do all of this. The results are improved torque, horsepower and, in some cases, even better emissions. The tradeoffs of a dual-overhead-cam cylinder head are few and include those of weight, cost and complexity of parts. Installing cams in a dual-overhead-cam head can also be more challenging and is generally a bit more involved than when working with single-overhead-cam cylinder heads.

The Perfect Camshaft

The idea of the perfect cam exists but you can't have it. If you could, it would maximize engine efficiency and power output at every engine speed. And it would do it without sacrificing drivability, reliability, emissions or fuel consumption. It would also do all of this—move the valves up and down—instantaneously, without friction and vary throughout the powerband. The scenario is an impossible one, even if we forgot about half of those things. Instead, you've got to choose a cam that's best for your application and be prepared to compromise. Some cams are designed for maximum top-end power at the expense of low-end response; others, the opposite. And in the case of the majority of production vehicles, emissions and fuel consumption almost always trump horsepower and torque production. Before settling on a cam, be sure that your priorities are in order because here more than anyplace else, you can't have it all.

|

|