Few people outside of Mazda's RE research department know more about rotary-powered Mazdas than Jim Mederer, co-founder and chief engineer at Racing Beat. Founded in 1971 by Mederer and Ryusuke Oku, Racing Beat has been racing rotary-powered Mazdas ever since, having filled shelves with trophies and putting its name in the record books along the way. In 1978 the company's first-generation RX-7 set a Bonneville top-speed record of 184 mph. In 1983, its IMSA RX-7 won the GTO class at the 24 Hours of Daytona. In 1986, its FC RX-7 set a land-speed record at Bonneville of 238 mph. And after a dramatic 225-mph rollover on the salt flats the year before, in 1995 Racing Beat's FD RX-7 bumped that record up to 242 mph. The company has worked closely with Mazda on a number of projects and even developed a single-rotor engine for NASA. Simply put, Racing Beat has learned a thing or two about rotary engines by putting them to the ultimate test in some of the most grueling motorsports events in the world.

|

Racing Beat co-founder and chief engineer Jim Mederer has earned his belt buckle the old-fashioned way, by tuning rotary-powered Mazdas to perfection for almost 40 years and surviving a 225-mph rollover at Bonneville. Search "Mazda RX-7 crash at 255 mph!!!" on YouTube for the Discovery Channel's recap of the crash.

|

Racing Beat co-founder and chief engineer Jim Mederer has earned his belt buckle the old-fashioned way, by tuning rotary-powered Mazdas to perfection for almost 40 years and surviving a 225-mph rollover at Bonneville. Search "Mazda RX-7 crash at 255 mph!!!" on YouTube for the Discovery Channel's recap of the crash.

If you read Part 1 of this story in last month's issue, then you already have a good sense of where the Wankel rotary engine design came from and evolved into. It's all well and good to understand the history and mechanics of the rotary, but what if you actually want to own a rotary-powered Mazda? What should you be looking for? To answer these questions, Racing Beat's Jim Mederer has very generously shared his thoughts so you can go RX shopping with confidence.

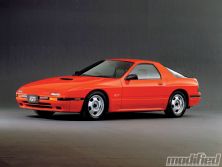

Rotary Shopping According to Jim, "Mazda has been improving the rotary constantly over the years. Therefore, it's logical that the latest models are the best - the most reliable, the most powerful - and they are. One exception to this pattern is the fact that in 1993 Mazda eliminated the engine-driven fan and uses an electric fan in its place. These fans are far less powerful than the mechanically driven fans they replaced. Along with this change, Mazda has packaged its engines very tightly, causing high temperatures to accumulate in the engine compartments. This has caused severe stress on engines that were otherwise very well designed, and as a result the reliability of the RX-7 and RX-8 has been less than it could have been. These problems have shown up most in hot weather and are difficult to fix since they are related to the shapes and arrangements in the engine compartment. It's a fact that rotaries are more sensitive to thermal stress than most reciprocating engines and will not tolerate high temps in either the water or the oil without undesirable results."

|

Mazda Rotary Evolution - Part 2

|

Mazda Rotary Evolution - Part 2

Jim went on to say, "The best way to check the health of a rotary is to do a compression check. These checks are subject to some interpretation. The starter-cranking rpm is an important question, along with the engine temperature, rotor compression ratio and the type of compression tester used. Rotaries typically crank around 300-330 rpm. If they turn above or below this number, the test result will be affected. Engines often have moderately different compression pressure hot versus cold, but this varies with the type of engine. You can use a conventional dial compression tester, but it is preferable to use a 'recording' tester that will take and display the pressure from each of the three sides of the rotor separately for comparison. Although the actual peak pressure recorded is important, it's equally true that you should have minimal fluctuations from one flank of the rotor to another as well as between rotors. The highest numbers I have ever seen are around 140 psi. Healthy late-model engines are usually around 110-130 psi, earlier engines 10 psi less. Engines below 90 psi may be hard to start, though they may still make normal power. The key is to watch for evenness between the pulses and between the rotors."

Rotary Tuning So you've found a rotary-powered Mazda you want to buy and have compression-tested the engine and it checks out perfectly. You plunk your cash down and take your new RX home, where the next step for go-fast geeks like us is to make it more reliable as well as more responsive and powerful.

According to Racing Beat's Jim Mederer, "Cooling is the most critical concern when using a rotary hard. Start by inspecting the radiator and oil cooler(s) for debris (sand and bugs). If the fins aren't clean and straight, either fix it or install a new radiator and/or cooler. Mazda has a very good fin design, but it gets plugged easily because it's so small. While you are there, inspect the seal of the shroud to the radiator. If it isn't sealed, fix it."

In terms of improving cooling beyond the stock system, according to Jim, "The only thing that we have found to help is to install a 'spoiler' lip of 1/16-inch-thick ABS plastic under the front crossmember, 3 inches high and extending as wide as possible across the underside of the car. It will hit the ground in cornering, but the low pressure it creates at the engine compartment air outlet is helpful. If you want to see an example, just look under the front of a C6 Corvette. Thicker radiators have limited value because they tend to restrict airflow even more than stock. And if you don't have an accurate temperature gauge, at least on the cooling system (and preferably on the oil inlet system too), install one. Stock gauges are inadequate. We recommend that you never exceed 195 degrees Fahrenheit water outlet temp and 205 degrees oil inlet temp at high power. At light power, the engine can tolerate somewhat higher temps, but don't push it. We aren't saying that the engine will fail if you exceed these temps, we are saying that higher temps will shorten the engine's life at an increasing rate."

According to Jim, FC and FD owners need to beware of fuel delivery problems."Fuel pumps, fuel filters and the wiring and relays that supply the pump with power - none of these age gracefully. The pump performance decreases, the filter becomes restricted and the wiring, which wasn't very large to begin with, accumulates resistance at all contact points, reducing voltage to the pump. A new stock pump and filter are good starting points, but the wiring problems are tougher. Start by measuring the voltage at the fuel pump with an accurate voltmeter. With the engine idling, the voltage at the pump must be no more than a few tenths of a volt less than battery voltage. If it is, you have two choices: find the locations where the voltage drops occur and correct them or run new, larger wiring to a new relay at the pump, controlled by the old pump wiring. This isn't fun, but it's necessary in many cases. To date, the RX-8 hasn't shown this problem, but you would be wise to check the pump voltage anyway."

In terms of other reliability issues to be mindful of, Jim recommends you don't spin the stock turbo (on turbo FCs and FDs) beyond 14 psi. If you do, there's a real chance of overspeeding the turbo, killing the turbo bearings in the process and sending parts of the compressor through the engine. Jim also recommends that for track days you install two step colder spark plugs gapped to 0.020-inch to avoid possible detonation at high power. Just keep in mind that although colder spark plugs that are clean do not reduce power, but they can foul fairly quickly, so try to use them only during competition or track days.

With the reliability side of your RX sorted out, you'll no doubt start looking for ways to increase engine output. According to Jim, "Once you have the engine temperatures and fuel delivery under control, the best way to increase power in a turbo RX is to install a low restriction exhaust system. The lower backpressure helps in two ways: it improves exhaust scavenging from the engine and it raises boost pressure. As long as you have good cooling and good fuel delivery, the increase in power can be impressive and fun. The addition of a low-restriction intake duct and filter can offer a bit more improvement. The same is true for normally aspirated engines, but the gains are much more modest."

Beyond the bolt-on options available from rotary specialists like Racing Beat, the sky is the limit if you have the budget to match. It's not hard to find examples of race-winning RX-7s and RX-8s, including the awesome Grand Am GT class Speedsource RX-8 that took the win at the Rolex 24 at Daytona back in January of this year.