Direct fuel injection isn't exactly a new idea. It's actually been around since World War II, when it was used on aircraft engines designed by the Germans and Russians and has been used in diesel engines for decades. But with more and more high-performance, gasoline-powered cars moving away from conventional multi-port fuel injection in favor of direct fuel injection-including sport compacts like the Mazdaspeed3 and Chevy Cobalt SS, as well as world-class sports cars like the Porsche 911 and Audi R8-it seems timely to discuss this technology in order to better understand how it may impact our ability to tune our favorite cars now and in the years to come.

|

Direct Fuel Injection - Adding Fuel To The Fire - Tech Talk

|

Direct Fuel Injection - Adding Fuel To The Fire - Tech Talk

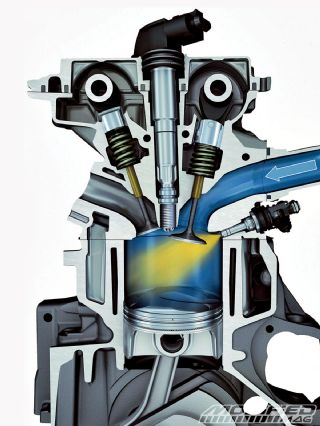

So what exactly is direct fuel injection (DFI), how does it differ from multi-port fuel injection (MPFI) and how does it improve engine performance? As the name implies, direct fuel injection (sometimes referred to as gasoline direction injection), injects fuel directly into the combustion chamber, rather than into the intake manifold runners or the cylinder head ports, as is the case with conventional multi-port fuel injection. The other major difference between MPFI and DFI is that direct injection fuel pressure is as much as 50 times higher than standard port injection, with DFI pressure well over 1,000 psi being the norm while MPFI pressure is usually around 50 psi, depending on the system's design.

The advantages of injecting fuel directly into the combustion chamber at very high pressure are numerous. Combined with the sophisticated ECUs featured in today's vehicles, DFI allows for greater control of how much fuel is injected into the cylinder and when/where exactly it's being injected. As previously mentioned, with conventional port injection, fuel is injected into the intake manifold runners or cylinder head ports, where some of the fuel washes along the walls as it mixes with the incoming air charge. This makes it difficult to precisely control the exact amount and timing of the fuel entering the combustion chamber, but with DFI the injector nozzles are positioned within the combustion chamber for an ideal spray pattern and accurate targeting of the ignition spark and the air immediately around it. This gives DFI superior control of the dispersion and consistency of the fuel being injected into the combustion chamber, enabling what is known as a "stratified mixture" or "stratified charge."

A stratified charge is when the air/fuel mixture is concentrated around the spark plug and the air at the marginal areas of the combustion chamber remains pure (free of fuel). This in turn allows a leaner burn, particularly at part throttle and low engine loads, resulting in improved fuel efficiency and reduced hydrocarbon emissions. Volkswagen claims its direct injection system improves fuel economy by up to 25 percent, while Audi claims a 15 percent improvement with its DFI system. Chevys with DFI engines are seeing similarly impressive results, with a 10-15 percent increase in fuel efficiency.

With improved fuel dispersion and control, DFI offers the added benefits of improved cylinder and piston cooling, which means higher compression ratios and more aggressive ignition timing can be used. And as you already know, with high compression and more aggressive ignition timing you get more power, and more power is good! Porsche, for example, has seen horsepower and torque increases of 5 percent and 4 percent, respectively, on its LeMans V-8 race engines, which is a huge improvement to see on an engine that is already highly optimized. Cadillac sells the CTS with both a port-injected or direct-injected version of its 3.6-liter V-6 engine. The port-injected version makes 263 bhp, while the direct-injection version makes 304 bhp while getting slightly better fuel economy and doing so on regular unleaded fuel.

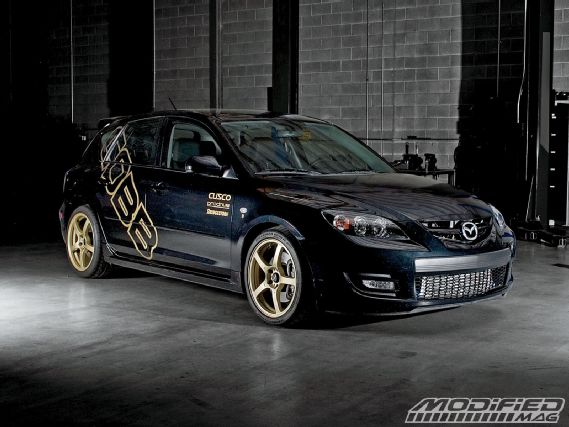

DFI is especially effective when combined with boost, which is exactly why we've seen Chevy combine it with the Cobalt SS' turbo engine and Mazda combine it with the turbocharged MZR engine featured in the Mazdaspeed3 (as well as the MS6 and CX-7). To get a better grasp of what tuning challenges and potential advantages DFI offer power-hungry Cobalt SS and MS3 owners, I turned to Trey Cobb of Cobb Tuning, owner of one of the leading tuning companies in the country.

|

Direct Fuel Injection - Adding Fuel To The Fire - Tech Talk

|

Direct Fuel Injection - Adding Fuel To The Fire - Tech Talk

Cobb Tuning has developed its famous AccessPORT ECU tuning tool for the Mazdaspeed3 (as well as a whole host of bolt-on performance parts), so you can be sure the company has learned a thing or two about DFI. When I asked Trey about the challenges of cracking the MS3's ECU such that the AccessPORT can be used to reflash the fuel and ignition timing maps (along with many other features), he said, "Very few DFI-specific challenges came up during initial development of the AccessPORT. There are some unique aspects to the ECU programming on DFI motors, but overall the higher level aspects to the engine management (fuel tables, ignition advance, camshaft advance, boost control) are virtually identical to what we normally see in non-DFI applications. The greater challenge is actually coming from the more sophisticated torque control logic that is increasingly being implemented by the OEM's [as a form of traction control]." Impressively, the AccessPORT for the MS3 does allow gear-specific tuning of throttle position and boost levels such that the OE torque control system is tunable.

When I asked Trey about any limitations to potential power output with DFI engines, he felt that, "The high-pressure (DFI) fuel pump on the MS3 engine is a limitation. The factory components also tend to have a fair degree of variance and have been subject to manufacturer recalls. We've found that the factory pump may be suitable for higher power levels on some cars, but not on others. The manufacturing variations seem to have a greater impact on the pump's ability to maintain the necessary fuel rail pressure, so much so that on some cars the factory pump is only just barely able to keep up with factory power levels. This is where having the ability to datalog your fuel rail pressures [available through the AccessPORT] is critical to verifying accurate and safe fuel delivery." There are, however, aftermarket fuel pumps available for the MS3 and replacing the OE unit is not overly difficult (though you do have to be extra careful when dealing with a fuel system with more than 1,000 psi of pressure), but they are substantially more expensive than non-DFI fuel pumps.

When I asked Trey if he thinks we'll see some really highly tuned DFI engines pumping out big horsepower numbers, he responded, "Certainly, and with respect to the Mazdaspeed3, the next hurdle to overcome is with the camshafts. The four-cylinder MZR engine is not designed to operate at a very high engine rpm range, due in part to the limitations of direct injection. There simply isn't as much time to inject fuel per cycle as there is with non-DFI setups, thus lowering your maximum rpm ceiling. The camshaft profile for the MZR motor was designed specifically for lower to midrange power output, and the engines are tremendously efficient in that range. Even with how well air fills the cylinder and manifolds, the engine's volumentric efficiency [torque] decreases significantly at higher (6000-plus) rpm. Horsepower is dependent on rpm, so to get the horsepower numbers people are looking for, a solution needs to become available to increase the MZR's VE up in the higher rpm range. That will involve, I suspect, different camshafts and potentially higher flowing injectors in addition to the normal supporting modifications (fuel pump, turbo, manifold, intercooler and so on). The limitation of time to inject fuel at high rpm will still exist, as that's inherent to the nature of DFI systems."

I then asked Trey if he could foresee a point where DFI will represent a meaningful advantage to tuners, so much so that people will be looking for ways to convert from port injection to direct injection? "DFI offers a precision of control significantly better than non-DFI setups. So, in theory, yes, you should be able to make more power and, most importantly, consistent power. So I think DFI will eventually become a sought-after advantage. However, I do not foresee people converting their existing non-DFI engine over to DFI in the near term. The systems are (at least currently) too complex and ultimately need to be done with the mindset of creating an entire system. Engines are mechanically designed to have DFI or not. Unless a complete package can be developed with a low enough cost of entry, I think we'll only see DFI used on applications it came with from the factory."

|

Direct Fuel Injection - Adding Fuel To The Fire - Tech Talk

|

Direct Fuel Injection - Adding Fuel To The Fire - Tech Talk

With more and more gasoline-powered vehicles being equipped with DFI systems from the factory, including machines from manufacturers like Mitsubishi, Subaru, Mazda, Toyota, Isuzu, BMW, VW, Audi and GM, it's safe to say the aftermarket will find ways to take full advantage of the benefits associated with this technology. With companies like Cobb Tuning taking on the challenge already, you can rest assured that your DFI car will have just as much (if not more) tuner potential as its MPFI counterparts.