| K-Series Oil System Upgrades - Under Pressure

| K-Series Oil System Upgrades - Under Pressure

Rethinking the k's oil pump

The K-series is going on six years now and parts development for the platform has arguably surpassed most everyone's expectations. Compare it to the B-series, which six years after its introduction had nowhere near the amount of support the K does. It isn't the new kid anymore; its strengths and weaknesses are well known. One such weakness lies with the oiling system. It's a minor one though, which means the solution is best suited for competition-bound, race engines-not necessarily your average street-built K20A-although the mod certainly won't hurt. The flaw? The oil pump, specifically its drive gear. Few people understand the inner workings of the K-series better than HyTech Exhaust's John Grudynski, the brains behind all of this. So that's who we went to.

The Problem

Honda has earned a reputation for manufacturing parts with leftover potential. That's why its engines are so tunable. Who else makes a stock forged crank that can handle 700 hp? It can be argued that certain things have been dictated by budgets not power potential over at Honda as of late though. One such result is the K-series oil pump that tends to cavitate past that 8,700rpm mark. The problem doesn't sound so serious, especially since even the high-revving K20 Type R valvetrain is limited to 8,600 rpm, but for those building serious drag or road race engines, even street setups with high-end rebuilds, the right mods will tempt even the best of us to fool around in that upper powerband.

Most Honda oil pumps operate at one-to-one ratio crankshaft speeds. Take the B-series oil pump for example-it is, after all, driven directly off the crankshaft. Not the K's though-it operates at 1.6 times the crankshaft's speed. That's extremely fast, so fast that when that K20 spins at 8,000 rpm, that little pump is turning at an astonishing 12,800 rpm! It's no wonder it can't keep up, which is what leads to cavitation. So why would Honda do such a thing? The answer is both simple and smart. You see i-VTEC incorporates VTEC as well as variable cam timing. Both systems rely on oil pressure, and lots of it. Since the majority of camshaft movement happens at lower and middle engine speeds, driving an oil pump at such speeds might not provide enough pressure-especially if you're a Honda engineer and you want to keep the pump small. Overdriving the pump takes care of all of this, which is exactly what Honda did.

The Pump Fix

The HyTech fix begins with blueprinting the stock pump. The side clearance of the pump's gears is reduced from 0.0012 of an inch to 0.0008 of an inch. This helps better seal the gears against the housing, thus reducing leakage. The exit port where oil transitions from the pump to the block is fairly rough. Its corners create flow eddies, or turbulence, which restrict oil volume made available to the block. HyTech employs a hand-finished procedure that puts a uniform radius on the entrance, allowing for more oil to be fed through.

Not satisfied? Further oil pump fixes involve fitting the S2000's pump to the K, which features a different internal design with a larger gear and bigger ports. This isn't such an easy mod though, and you can't run the stock K-series aluminum pan with it. Not a good deal if you've got a new Si with the oil pan-placed motor mount. Enough with the S2000 pump then.

After cleaning up the K pump, HyTech goes one step further by reducing pump speed by 10 percent. Now engine speeds can reach 9,500 rpm before cavitation begins. That's high enough for just about any street or road race engine. HyTech also cuts a new gear from an OEM piece using a method accurate within 0.0002 of an inch. The process also leaves a superior finish on the surface of the newly cut gear.

Simply Baffling

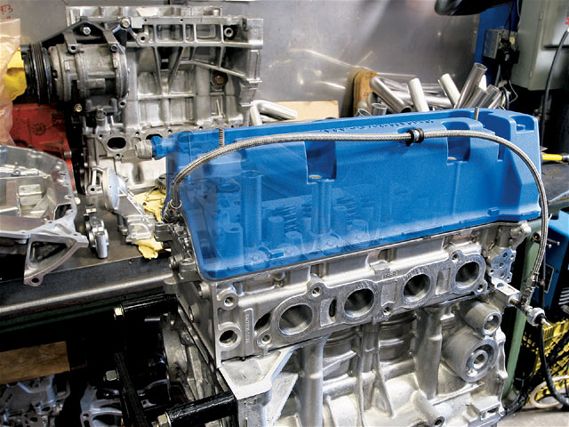

With all of this oil being pumped, the next problem is keeping it readily available. Like most street-bound engines, the K-series oil pan isn't baffled. A few NASA or SCCA corners and you'll quickly find out what happens when the oil pickup has no oil to pick up. HyTech's oil pan baffle eliminates this problem. It's made of 1/16-inch aluminum sheet metal and consists of 20 separate pieces. They're each bent, riveted, and fastened together to create the main structure. Five trap doors are included in the baffle, which are designed to swing just one way-they let oil into the baffle's center, not out. This ensures a generous supply around the pickup at all times, no matter what the car does. It also incorporates three anti-surge plates to keep the oil from running up the sides and rear of the engine, internally.

This concludes the competition oil pump setup portion of our program but stay tuned and we'll tell you about a way to protect your expensive upgraded valvetrain as well as keep those new aftermarket cams happy as pigs in slop, literally.

The Other Problem

Welcome back. Glad you could be here. There's but another K-series shortcoming. This time it involves camshaft lubrication. Oh, and this one applies to anyone who has put in aftermarket springs and retainers or even just swapped their cams. The K engine feeds oil to its cam journals internally through its number two cam tower, which then feeds oil into the camshafts and then distributes it to each journal. The number two tower features two small holes that are each only 0.05 of an inch in diameter. At low engine speeds the volume of oil feeding the cam journals is marginal, especially when combined with heavier valve spring pressures and thicker oil. To help this, another oil source is needed in order to supply adequate pressure to each journal. If you're thinking of simply hogging out the existing oil supply holes, don't. In doing so, you'd essentially override VTEC. The same oil that's used to feed the cam journals is the same oil that engages VTEC. This is precisely why the holes are small-to ensure adequate pressure. You may recall that pressure and volume are inversely proportional, meaning drilling that hole out will increase volume but reduce pressure.

The Head Fix

Here's the fix. Oil must be robbed from the main oil galley where the OEM oil pressure sending unit resides. HyTech makes a custom stainless steel tee fitting that allows the sending unit to be reused yet offers provisions for the oil we need. A -3 stainless steel braided oil line routes from the tee to the cylinder head's rear where it's tapped into the number five cam tower. Oil is then dispersed to the cam journals. It just so happens that in the back of the number five cam tower there's a preexisting 6mm threaded orifice. The hole must be drilled out in a two-step process. First with a 3/16-inch bit and then further to accept a 1/8-inch pipe tap. The hole is tapped and a -3 adapter fitting can be installed. The cam tower's topside is ready for machining. A 3/16-inch diameter ball-end mill is used to machine a 1/8-inch deep groove from one side to the other and a 3/16-inch bit is used to intersect this groove with the hole initially drilled on the cam tower's backside. Confused? Don't be. HyTech has got it all figured out.

The final step involves plugging the rocker shafts' ends where they enter the number five cam tower's rear. Custom aluminum plugs are machined and pressed into the end of both rocker shafts. Since oil's being introduced back into the engine this way, the shafts need to be plugged to stop the new oil supply from seeping into the rocker shafts, engaging VTEC.

The downside: All of this isn't so doable if you're without a mill. No problem though, HyTech does it all for $375. Just send in your number five tower and you'll get it back modified with everything necessary to make it work. A good deal considering it could save an expensive valvetrain. Don't forget, the K-series is easily Honda's best engine to date. It's got a great deal going for it. Addressing its downsides is the easy part.

Don't Touch That Spring

Here's an urban legend for you: It's been rumored that increasing an oil pump's spring pressure is a good way to remedy cavitation. This is wrong. The pump is designed to supercharge the inlet side with oil that comes from the pressure relief plunger. When the pressure relief spring begins to open it helps feed the rotor more oil and hold off cavitation. Added spring pressure prolongs the relief valve from opening at the desired time and stops the pump from helping itself feed the rotor with oil. Doing this makes the pump cavitate earlier, not later. The pump is also designed to run lightweight motor oil. The lighter the weight, the faster it flows. The faster it flows, the more oil to pump. The more oil to pump, the less likely the pump is to cavitate. All reasons why Honda did what it did.

But what does it cost?

Oil pan baffles (Type S, TSX, and Si): $335

Oil pump blueprinting: $90

Modified oil pump gear and new chain: $300 (plus core)

Cam oiling kit: $300 (includes machine work)