| Are synthetics really worth the price of admission? We put Lucas Oil's friction-fighting formula to the ultimate test on this B18C VTEC engine.

| Are synthetics really worth the price of admission? We put Lucas Oil's friction-fighting formula to the ultimate test on this B18C VTEC engine.

The friction-fighting properties of synthetic lubricants have been well established by now. Second only to making sure you change your oil at regular intervals is the need for a high-quality synthetic oil. Even if we disregard the performance benefits offered by the reduced friction, the improved lubrication and protection from thermal breakdown are reason enough to step up to the cost of synthetic lubricants. Not filling the crankcase with synthetics can be likened to running your turbo engine on low-octane fuel. Under most conditions, your boosted engine will tolerate the cheap stuff, but when you really need it most, the lesser octane can subject your turbo engine to deadly detonation. While the oiling situation likely won't be as dramatic, it is possible to spin a bearing or two under the heat of battle using conventional oil. Sure, synthetic oil is slightly more expensive, but a portion of the added cost can be recouped by lengthening oil change intervals since synthetics are less susceptible to contamination. But even if you do choose to schedule your changes every 3,000 miles, doesn't your performance engine deserve the good stuff?

| To illustrate the effectiveness of synthetic oil, we ran Lucas Oil's own high-performance 20W/50 against their 5W-20 synthetic oil.

| To illustrate the effectiveness of synthetic oil, we ran Lucas Oil's own high-performance 20W/50 against their 5W-20 synthetic oil.

The Rundown

While their increased longevity and heat-resistant properties make synthetic oils desirable, the additional power realized through reduced internal friction can be considered the icing on the cake. To illustrate the potential power gains offered we compared synthetic oil against conventional (non-synthetic) oil in three different back-to-back tests. Part one looks at both a normally aspirated and a turbocharged B18C VTEC combination. We follow this up by testing super lightweight racing oil on a 4AGE Toyota. The naturally aspirated/turbo test was made possible since we were breaking in a new turbo engine and were afforded the opportunity to run it normally aspirated before subjecting it to boost. Running the engine in both normally aspirated and turbocharged states allows us to test the various oils' effects on both combinations. Would the added strain of the higher power output turbo engine yield different results or would the power gains offered by the reduced friction remain the same with both combinations? Questions like these are why we go to such trouble in the first place.

| The shortblock is topped off with a complete Dart head assembly and Skunk2 camshafts.

| The shortblock is topped off with a complete Dart head assembly and Skunk2 camshafts.

The Naturally Aspirated Setup

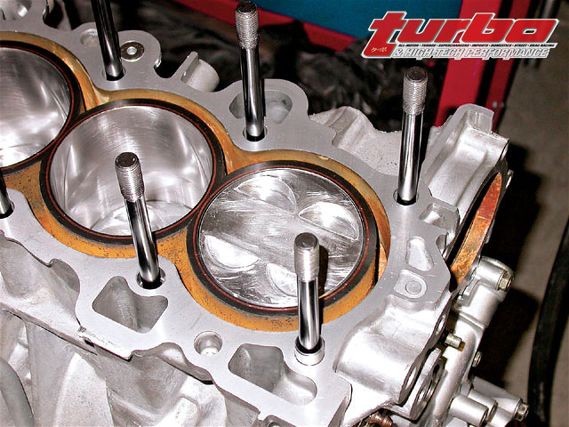

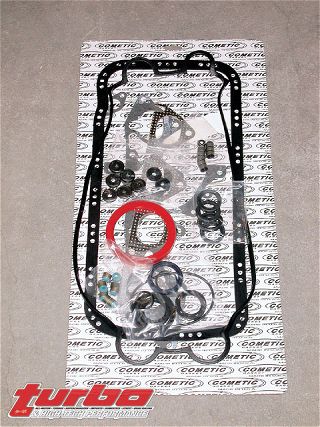

The turbocharged test engine began life as any other B18C block, but was quickly augmented with a set of sleeves to allow for an increase in bore size from 81mm to 84mm. The increased bore is matched with an 87.2mm crank, a set of Probe Racing forged connecting rods and forged aluminum pistons. The shortblock is topped off with a CNC-ported Dart head, a set of Skunk2 Stage 2 camshafts and a matching Skunk2 intake manifold. Additional features include a complete Cometic headgasket set, ARP head studs and Skunk2 timing gears. The engine is also equipped with a modified AEM fuel rail designed to let us use the larger Bosch-type injectors. The naturally aspirated engine uses 36 lb/hr injectors, while the turbo is fitted with 72 lb/hr ones. Both cam timing and ignition timing are dialed in as is the air/fuel ratio using the Fast XFI engine management system. The Fast system is what allows us to produce such repeatable power curves (within 1 hp). The naturally aspirated engine is also equipped with an A'PEXi header feeding a 3-inch open exhaust.

| Our test engine features a sleeved B18C block bored to accept 84mm flattop pistons from Probe Racing.

| Our test engine features a sleeved B18C block bored to accept 84mm flattop pistons from Probe Racing.

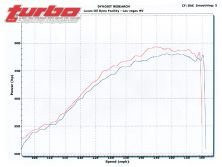

The Naturally Aspirated Test

The first order of business was to get the new engine up and running and subjected to its break-in procedure. Our computerized break-in procedure varies applied loads and engine speeds for 30-minute sessions. Once completed, we can dial in timing and air/fuel ratios for full-throttle conditions and then swap the oil and filter. We filled the Honda crankcase with Lucas 20W-50 conventional oil for our first phase of testing. The oil was brought up to temperature (190 degrees), while air and coolant temperatures were kept constant. With the conventional oil, the normally aspirated B-series engine produced 203 hp and 150 lb-ft of torque. Though we hoped for a bit more, we can't forget the fact that this low-compression engine was really built for one thing-boost. Subsequent runs resulted in repeated power figures. Following our first stage of tests, we drained the oil and swapped out the filter. After filling the crankcase with an equal amount of 5W-20 Lucas synthetic, we were rewarded with an immediate 8hp jump. Naturally, the synthetic oil was run at the same temperature as the conventional oil. The combination of the viscosity change and synthetic makeup improved power output to a total of 211 hp. As expected, the power gains increased with engine speed-most notable of which was near redline.

| Cometic supplied a complete gasket set including the necessary multilayer steel headgasket designed to work with our 84mm bore.

| Cometic supplied a complete gasket set including the necessary multilayer steel headgasket designed to work with our 84mm bore.

The Turbo Setup

Following the proper break-in procedure and the normally aspirated test, we fitted the turbo system to our B-series. The turbo configuration consists of a custom turbo manifold from HP Performance feeding a T72 Turbonetics turbo. Since this particular engine is destined for a record-breaking land speed car, the turbo was sized to produce optimum power near peak engine speeds. For street applications, this turbo is just too large, but since we only care about maximum power from roughly 7,500 rpm to 8,500 rpm, the combination produces boost numbers that actually exceed backpressure numbers-needless to say, this is difficult to achieve. The T72 feeds a single-core, air-to-water intercooler, though in the car we rely on a more efficient dual-core system. The injectors were swapped for the larger set and a TiAL wastegate was put in charge for boost control. For this test, we ran city water, not the generally hotter dyno water, through the core since we were running our oil test at a reduced boost level of only 16 psi. The key to successful testing is repeatability. Turbo engines, especially high-horsepower versions, can be temperamental and as such, call for a regimented procedure and precise tuning to achieve the kind of repeatability we require.

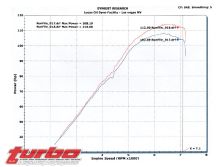

The Turbo Test

After fine-tuning the Fast XFI system with the new injectors and race fuel, the turbo engine showed the kind of repeatability we were looking for. The air/fuel and timing curves were perfect, while our start and test procedure all but ensured the same amount of heat energy and therefore boost pressure supplied by the turbo. The circulation through the air-to-water intercooler remained constant as did the cam timing and intake air temperatures. With each variable accounted for, all we had to do was make a few runs with the conventional oil and then again with the synthetic. Lucas suppled the oil required to get the engine up and running properly and allowed us to run a pair of back-to-back tests. Equipped with the conventional 20W-50 oil (again at 190 degrees), the low-boost turbo engine produced 481 hp at 16 psi. After swapping in the 5W-20 synthetic oil, peak power numbers jumped to 492 hp at an identical boost level-of course, air/fuel ratios and timing remained constant. Once again, the Lucas synthetic oil upped the power output of our turbo test engine by as much as 10-plus hp.

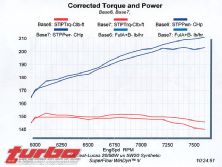

The Other Test

Our final test run on the Dynojet chassis dyno involves a 4AGE Toyota engine. The '89 Toyota Corolla GTS is equipped with a high-mileage 1.6L twin-cam 4AGE. The four-valve engine features a custom air intake and cat-back exhaust, but is otherwise completely stock. The oil change was a move to increase the engine's power output in preparation for the endurance race, the 24 Hours of LeMons. The race pits vehicles against not just one another but against the possibility of even finishing in a car that, by the rules, can be worth no more than $500. Running the synthetic oil was one of our tricks to improve the performance of our low-buck race car. Like our turbo engine tests, the 4AGE was run first with conventional oil, making note of the oil, air and water temperatures as well as the air/fuel ratios and timing values, which we data logged for ensured repeatability. We then replaced the conventional oil with a new blend of ultralight race oil offered by Lucas. The conventional oil was a 10W-40 while the synthetic race oil checked in with a water-like 0W-5 weight. Though we were concerned about the viscosity, the oil pressure gauge indicated plenty of pressure, even with the engine at full operating temperature at idle. Run with the conventional oil (at 190 degrees), the 4AGE produced 108 hp. After switching over to the Lucas synthetic oil, peak power jumped to 114 hp with a gain of over 8 hp past 7,000 rpm. Perhaps it's safe to say that Lucas Oil's friction-fighting formula really does work.