| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

Part: 4 10,000 Rpm On The Engine Dyno And We Get...We last left this project with a three-part interview by our engine builder Larry Widmer, the man up to the challenge of building an engine capable of 150 hp per liter on pump gas. Larry is the owner of Energy Dynamics (Endyn) in Fort Worth, Texas.

In the last 40 years Larry has worked for Ford, Toyota, Penske, General Dynamics, MSD and Lockheed Martin. His engines have won an Indy 500, numerous NASCAR races and multiple Pro Stock titles. For about the last 10 years, he's been a big Honda guy and was ready and waiting for our challenge.

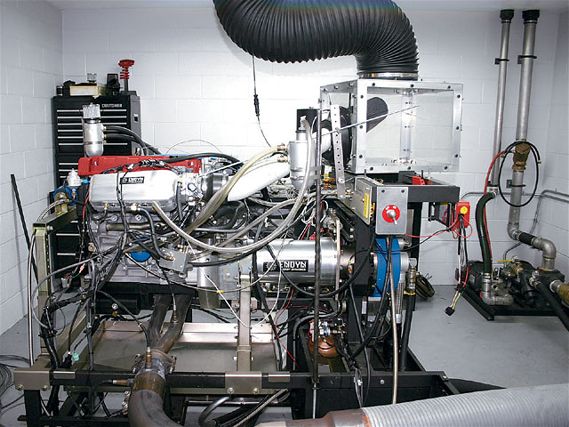

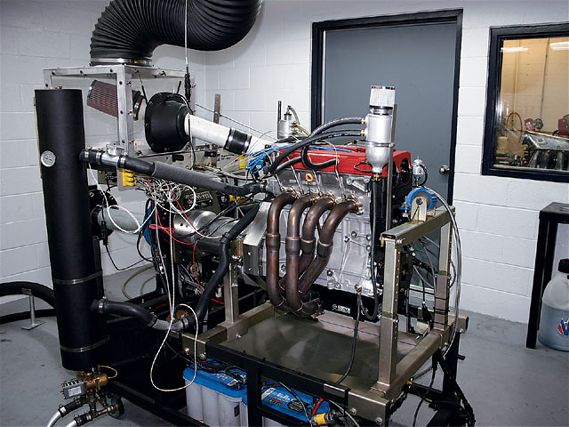

After the last three installments, we now know how the entire long block went together and it's time to put Endyn's engine to the test on the engine dyno. Endyn is one of the few engine builders with an engine dyno in-house. A Superflow SF-902 is something of an industry standard and can withstand up to 1000 lb-ft of torque, if you can deliver it.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

Endyn's dyno room is something any engine builder would kill to have. Built entirely of thick block, it's solid. There's also dedicated ventilation with climate controlled air for the room and the engine-it also has the most massive exhaust muffler we've ever seen. This lets Larry do dyno sessions late into the night without a complaint from anyone.

The important distinction between an engine dyno and a chassis dyno, like the Dynapack we'll use later, is that an engine dyno measures the power right at the flywheel. This is exactly how the car builders do it. When Honda says a K20 makes 200 hp, it has tested it at the flywheel, there's no transmission or other driveline connected to it. The company has to run all the power accessories like A/C and power steering plus the complete factory exhaust when doing its power ratings though.

The factory engine dynos have a shaft attached to the engine. A water brake is typically attached to the shaft to apply a load to it. Without it, the engine would just rev up until it over-revved. The running engine produces a twisting force measured in pound-feet. That force, times the rpm of the engine, divided by 5,252 is what gives us horsepower. So in reality a dyno doesn't measure horsepower, it measures torque and calculates horsepower.

Endyn's Superflow engine dyno works precisely the same as a factory dyno and has the same computer controls to regulate everything from temperature to throttle angle. Although at Endyn its test engine will only have an alternator and a basically open exhaust. This is a bit of a cheat, but for the power steering pump to have pressure it would need the entire steering rack and Endyn hadn't finalized a complete exhaust, nor was there room for it.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

Connected to the engine dyno with our Endyn-built Dart block, BBK 70mm throttle body and HyTech header, controlled by Hondata's best S300 tuning hardware and software, Larry used a preprogrammed routine to quickly break the engine in. A few hours later, with everything double-checked, it was time to do some tuning. Once Larry was happy with what he was seeing, the engine was run WFO to 7,000 rpm, then 8,000, then 9,000 and finally, a stratospheric 10,000 rpm-all the Superflow could take.

As the engine wound its way down, the results came up on the screen. The Endyn engine had hit a staggering 318.6 hp at 9,300 rpm on its best run, and it had routinely stuck 310, one horsepower above our goal. All this on pump gas and what Larry considered a "live-a-long-time" tune.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

With the day spent on the dyno, it was time to pack up our new engine and get it to UMS Tuning and Xact Dyno in Tempe, Ariz., for installation into our DB8. Big thanks to Tony Szirka and Kevin Nichols at UMS for not only installing the engine once, but twice. We learned the hard way that these tall Dart blocks can be very tricky to set the correct cam belt tension on. Larry didn't warn us and we turned the crank clockwise (normal rotation is counterclockwise) to checking something. This caused the belt to skip a tooth, something we discovered at start-up when the idle was really bad.

We alerted Endyn, and Larry wanted the engine back just to make sure nothing had gotten bent or was off. So out it went and in a box back to Endyn. That gave us some time to go through the car and get it ready for the chassis dyno and the dragstrip.

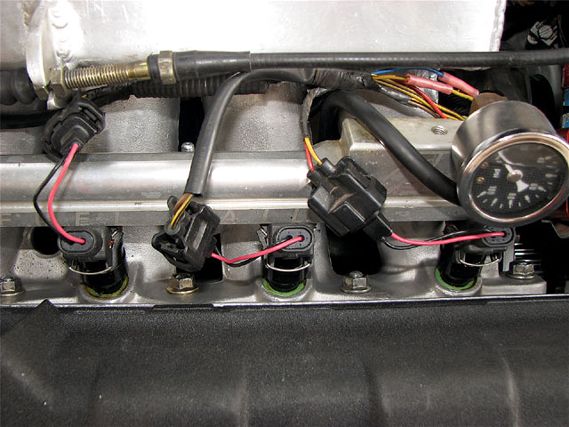

In addition to the BBK 70mm throttle body, BBK also supplied us with a 255 liter per hour in-tank fuel pump. A stock pump in perfect working order would have been OK, but we had precision balanced RC Engineering fuel injectors. The stock 240cc injectors would not have been capable of the 300+ hp the Endyn engine produced.

The added power and a new 10,000rpm redline also meant a stock clutch wasn't likely to keep up either. Centerforce came to the rescue with one of its Dual Friction clutch systems. The Dual Friction system basically lets the clutch behave like stock at engagement, but still holds at high rpm by using a different friction material on each side of the clutch; perfect for this engine. We also got an aluminum flywheel weighing in at just 7.1 pounds, just what a high-revving engine needs.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

A pair of companies handled the engine electronics. First, Hondata and its S300 engine management system. What's unique about the S300 is the fact that a daughterboard replaces the typical chip in the Honda ECU. The S300 has a simple USB connection letting you program it instantly. It also features enough onboard memory for up to 20 minutes of continuous data logging. The S300 is in a class of its own when it comes to engine management.

We also engaged PLX Devices for a wideband. The PLX R-500 wideband computer not only gives you air/fuel measurement from 10-20:1, but an EGT and a knock sensor monitor. Knock or detonation could quickly do damage to the Endyn Dart engine and running a 12.2:1 compression ratio on pump gas means detonation is only a bad tune away. Getting air/fuel right as well as being able to listen directly to the knock sensor is our main reason for choosing the R-500.

PLX had also just released its award-winning Intelligent Multi-Functional Display (iMFD). This cool piece looks like the standard circular gauge, but in reality it's a full color display featuring OLED technology. Capable of connecting to PLX air/fuel pressure and temperature monitors, you can program the display exactly how you want it using PC software.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

Our new 10,000rpm redline also presented us with another problem-a tach. An Integra Type-R dash reads to 10,000 rpm but we'd seen countless factory dashes that were a bit optimistic and the tach needs to be right on for this car. There was also no way we were going to stick a 6-inch Fast and Furious style tach on the dash. The whole idea is to be somewhat low-key here.

Racepak, maker of professional racing dashes and data logging equipment, just happened to have a street dash that would fit perfectly in the crescent-shaped Integra dash. For only $725, the 250-DS-UDXSR shows everything you need in a street car dash, from turn signals to an odometer and more, but it looks like a $10,000 Indycar dash. You also get oil pressure and temp sensors, the rest tap factory sensors. This should be an incredibly cool addition.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

Next time, we'll hit the chassis dyno to see what kind of differences there are from the engine dyno to the chassis dyno. Numbers abound from 10 to 20+ percent in drivetrain loss. We're expecting around 20 because we'll have the A/C and power steering connected as well as a full exhaust. Although it's midsummer, we'll hit the local dragstrip to see what kind of times we can get from the engine, our custom Gearspeed tranny and tough new Driveshaft Shop Stage 2 axles. Stay tuned one last time.

Where's The Project Car?

We Get Lojack To Make Sure It's A Happy Ending

If you've been a subscriber for a while, then you might remember the Feb. '05 story about how Hondas are one of the most jacked cars ever. In fact, there have been years where Hondas made up 50 percent or more of the top 10 most stolen cars. Nearly all of those cars are DOHC VTEC cars like the Civic Si or GSR.

At this point, our Endyn engine is worth more than the chassis, mostly because the car actually got to us as a theft recovery. Completely bare, it had been stripped by expert thieves taking everything but the doors and dash. To make sure it won't happen again, we went to the guys at LoJack.

LoJack uses a proprietary system that lets police departments track the location of a stolen car precisely enough to find it. The bad news is that you need to know it's missing and then report it to the cops before the tracking starts. The good news is that LoJack-equipped cars are recovered 90 percent of the time, many within a few hours. Even better, you pay for it once. There are no subscription fees and it can be transferred to a new owner, adding value to your car.

| Pound For Pound - Wrenchin

| Pound For Pound - Wrenchin

Recently, to make it even tougher for the bad guys, LoJack developed the Early Warning Recovery System. It consists of a Key Pass that an authorized driver keeps on his keychain. That tells the LoJack system, which is aware the vehicle is moving, to relax. Without the Key Pass, whenever the vehicle moves, you are contacted up to five different ways such as by e-mail or phone. You then verify and call the cops. This is probably the best protection from the worst of the worst, the thieves with tow trucks.

LoJack does its installations in secret, so we don't even know where the tracking transmitter is. It also has a dedicated battery backup and works in covered locations like parking garages. In doing our theft story back in 2005, we talked with law enforcement and they verified that LoJack is effective. According to them, the "experienced" thieves will steal a vehicle and ditch it someplace for a few hours just to see if it's LoJack equipped.

You can bet the LoJack sticker will be one of the biggest on this project car. We don't need to be sending the LoJack guys a story for their website, even if it does result in recovery.