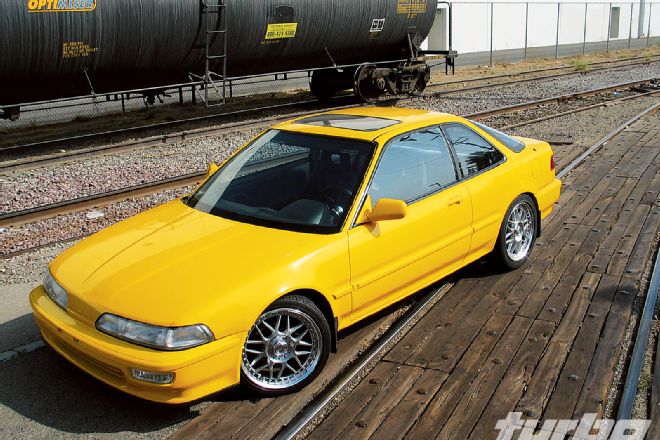

In last month's installment we pushed the performance of the B16A engine to the tune of 155.2 hp to the wheels with three simple bolt-ons. The B16A engine is like the Energizer Bunny, it just keeps going and going. Our B16A tester is more than 15 years old (going from the date stamp on the cylinder head) and already logged more than 50,000 miles since its acquisition from the local used engine depot.

If you account for the mileage on the engine before we purchased it, we probably have an engine that has logged more than 80,000 miles. If you consider the mileage on our B16A engine you'd appreciate how impressive the numbers the engine generated on the dyno. That is nearly 100 hp per liter to the wheels!

For this installment we got serious with the help of Peak Performance products from Dynamic Autosports. The easiest way to increase power in a DOHC VTEC engine is by adding a set of performance camshafts.

There are three different stages of camshafts available from Peak Performance. The Stage One is the mild street variant while the Stage Three is the most aggressive, meant for built engines and hard street use. We, of course, elected to use the Stage Two version.

Using the Stage Two camshafts entails upgrading the valve springs and retainers as well. We used Peak Performance's high-performance dual-spring valve-springs and heat-treated titanium retainers. By upgrading the valvetrain we are avoiding two major problems. The most important problem to prevent is coil bind, which can be caused by high-lift cams. Besides worrying about coil bind you also need to make sure the valve springs are capable of preventing valve float at high rpm. Valve float can not only decrease power output but worst-case it can cause major engine failure.

The titanium retainers are an option for the Stage Two cams but we went ahead and installed them too for peace of mind. The titanium retainers are not only stronger than the stock piece but are also lighter.

Installing valve springs and retainers on a cylinder head while it is still attached to the block is a tricky proposition. If you remove the valve springs the valve will drop into the cylinder due to gravity. To prevent the valves from dropping, we pressurized the cylinder with compressed air before removing the valve springs and retainers. Once the cams, springs and retainers were installed the top end was buttoned up.

A set of Peak Performance adjustable cam sprockets were installed to help fine-tune the powerband once we got back to the dyno. Whenever installing a performance camshaft follow the manufacturer's procedure for proper break-in. After break-in our B16 purred like a kitty. Surprisingly, the car's idle felt relatively stock with the exception of a small rumpity-rump caused by the overlap due to the cam's longer duration.

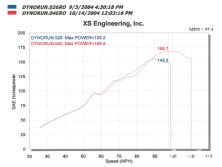

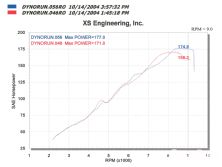

On the dyno the Peak Performance camshafts kicked serious butt. Our last dyno run with the stock camshafts generated 155.2-peak hp. The Peak Performance Stage Two camshafts registered 168.8-peak hp, which is an increase of 13.6 hp.

Also, the stock cams would quickly run out of breath by 8000 rpm. The Peak cams pulled all the way to 9200 rpm. At 8000 rpm there was a difference of 20-plus hp with the Peak cams over stock. Hearing the B16A sing at 9000 rpm is quite addicting but also scary at the same time.

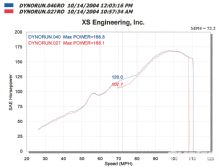

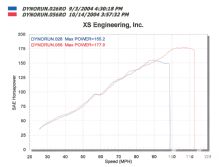

Our next bolt-on was manufacturing a test pipe for dyno purposes. Since the original stock exhaust manifold was attached to a gutted catalytic converter we wanted to see the difference in power between a high-flow cat and a test pipe. Once the test pipe was fitted it was back on the dyno. The exhaust definitely got louder since there was less restriction. The test pipe registered 171.0 hp, an increase of 2.2-peak hp but at 6500 rpm we witnessed an increase of 7.7 hp. Throughout the powerband the test pipe generated about 3 to 4 hp more than the high-flow cat.

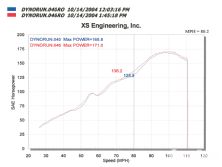

Our last modification this month was the Peak Performance intake manifold. The cast-aluminum intake manifold is similar to the Integra Type-R with the exception of a much larger plenum and runners. Our guess was that the Peak Performance manifold would generate power up top but lose in the mid-range due to the loss of air velocity from the larger plenum and runners.

Our theory was somewhat correct. On the dyno the Peak Performance manifold soared from 8000 to redline but lost some from 7000 to 8000 rpm. We were positive the manifold would lose more power below 6000 rpm but it didn't.

Now redline on the engine is in the neighborhood of 9400 rpm. Yes, the block is stock! At 9000 rpm the manifold showed an increase of 16.6 hp. Now peak power checks in at 177.0 hp, 6.0 hp more than the stock manifold.

All in a days work-three bolt-ons and 21.8 hp...on a B16A engine that has loggedmore than 80,000 miles at that. We are now producing more than 110 hp per liter to the wheels. The engine is producing roughly 195 hp at the flywheel, estimating a 10 percent loss through the drivetrain.

For our next installment we'll be doing a port and polish job fon the cylinder head for better flow. With the proper cylinder head tricks our buzzin' bumble bee Integra could very well break into the 190-hp barrier. Until next time, see you at 9000 rpm.