For 2001, GM released its 6.6L Duramax engine, which, at the time, was considered by many to be the most advanced diesel powerplant ever installed in American pickup trucks. The fact that the same basic design has lasted for more than a decade just confirms how amazing the engines really are.

However, early Duramaxes aren't problem free. The biggest issue with '01-to-'04 and 1/2 LB7 engines is their fuel injectors' propensity to fail, typically before an engine reaches 100,000 miles. When an LB7 injector fails, it can dump an enormous amount of excess fuel into the engine, often at very low speeds (such as idle, for example). When this happens, the extra fuel isn't burned; it seeps into the oiling system and thus starts filling the engine with diesel fuel.

Unfortunately, Duramax injectors are both expensive and difficult to reach in the engine compartment for replacement, which prompted GM to extend its injector warranty to 200,000 miles.

The LB7 is otherwise a very reliable engine. As such, many owners will go through the hassle of replacing some or all of the injectors in their '01-to-'04 and 1/2 Duramax oil-burners with the idea that they'll be keeping their trucks for another 100,000 or 200,000 miles.

We swung by Xtreme Diesel Inc. in Chico, California, to witness an injector swap on a 168,000-mile '03 6.6L that actually has several bad injectors. Although all eight squirters are being replaced, space constraints (and redundancy) limit our focus to just the passenger-side bank of four. A lot of the labor lies in actually getting to the injectors themselves, so if one or two are bad on a side, it's common to replace the entire side. Follow along as we right an LB7 engine's most common wrong: bad injectors.

| Duramax White Smoke

Diagnosing bad injectors on a 6.6L Duramax LB7 engine is usually pretty easy. The owner of this '03 Chevrolet Silverado 2500HD complained of white smoke coming from the tailpipe under load. As you can see, there's a whole lot of it when the engine is revved up. While white smoke can also indicate coolant bleeding past a blown head gasket, on an LB7 it usually means excess unburned fuel.

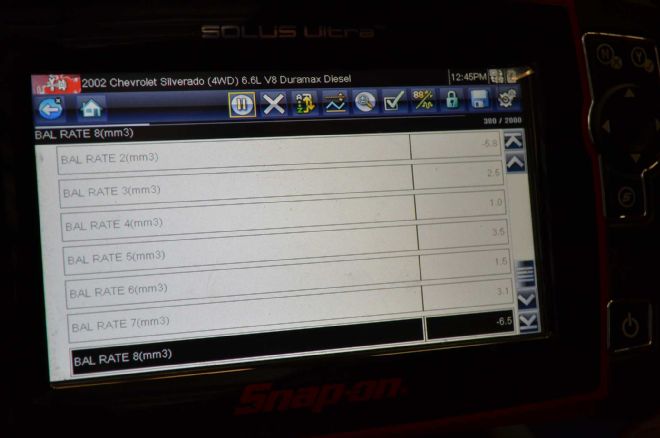

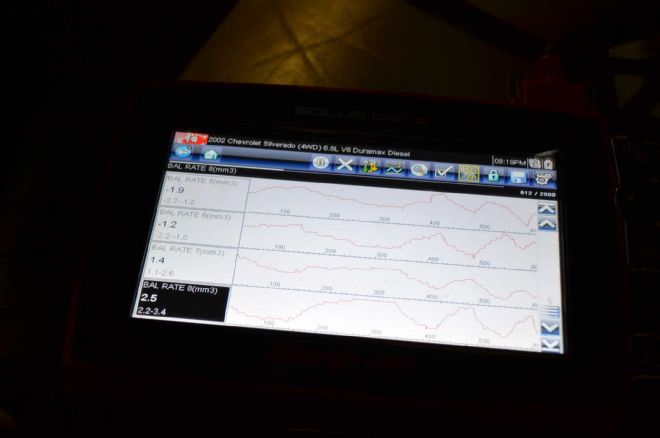

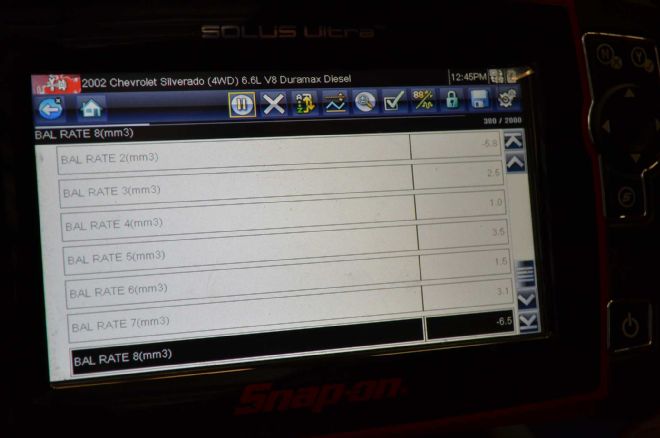

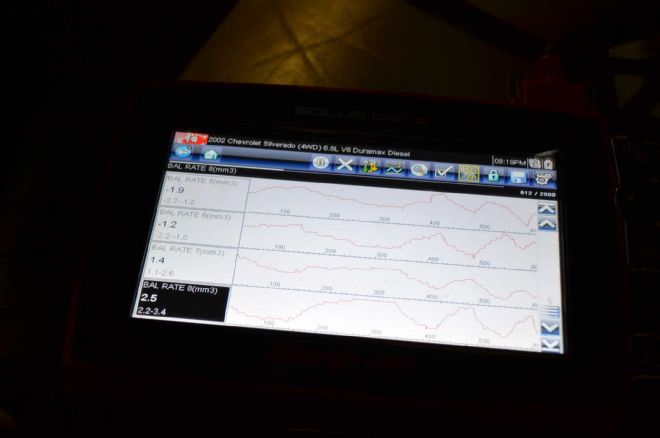

| Duramax Injector Balance Rates

One sure way of testing the injectors is to check balance rates, which most diesel shops can do using a scan tool. Balance numbers of -5.8 and -6.5 on this truck showed the ECU was frantically trying to get fuel to lean cylinders to compensate for the bad injectors. A balance rate of -4 is considered the maximum allowable, while "good" is usually ± 2.

| Duramax Intake Removal

Xtreme Diesel Inc's. owner, Jason Carrier, starts the procedure with a simple first step—removing the intake.

| Duramax Filter Housing Removal

With the intake out of the way, next comes the fuel filter, housing, and lines. This assembly has to be removed in order to access the valve cover.

| Duramax FICM Removal

Some computer hardware needs to be removed, as the fuel injection control module (FICM) is mounted on the passenger-side valve cover.

| Duramax Computer Mount

Even with the main computer out of the way, its mount, as well as tons of rubber and electrical connections, also has to be temporarily relocated. Jason only removes exactly what he needs to minimize the possibility of a crossed hose or line during reassembly.

| Duramax Injector Lines

This is the line from the common-rail to the injector line, which is finally exposed. Upper and lower valve covers still need to be removed in order to access the injectors.

| Duramax Upper Valve Cover

With the upper valve cover off, the LB7's valvetrain and injectors are finally exposed.

| Duramax Injector Wires

Next, Jason removes the electrical connections to the injectors. Since these wires lead a very hard life, it's a good time to inspect them for any damage.

| Duramax Lower Valve Cover

The lower valve cover can now be removed, which is one of the final steps before injector removal.

| Duramax Injector Line

With the lower valve cover off, Jason then takes out the injector return line, being careful not to strip any of the bolts that secure it. Jason says these fasteners can be easily stripped during this process and must be replaced if that happens.

| Pulling Duramax Injector

This is one of the few specialty tools needed for getting the extraction done—an injector puller. It's available at many tool supply trucks or stores, as well as online.

| New Bosch Duramax Injector

After removing all four injectors on the passenger side of the engine, Jason is ready to install the new LB7 injectors. He says he only uses brand-new Bosch injectors, as he has seen other injectors fail in as little as 30,000 to 40,000 miles and have to be replaced (again).

| Duramax Injector Torque

After the injectors are placed in the injector cups, Jason secures the hold-downs with the recommended 37 ft-lb of torque.

| Duramax Return Line Install

With the new injectors in place, the reassembly process then begins, and it is basically the disassembly in reverse. First, the fuel rail is installed, along with new bolts (if needed.)

| Lower Valve Cover On

With the new injectors, electrical connections, and lower valve cover reinstalled, it's now time to clean the upper valve cover and install it. Jason uses gray RTV silicone to ensure a leak-free seal between the head and the cover.

| Upper Valve Cover On

| Duramax Bosch Injector Lines

After thousands of miles of hard use, the factory injector lines can often be contaminated with rust, as is the case here. In order to steer clear of wiping out a brand-new set of injectors, Jason always recommends replacing the injector lines with new Bosch pieces.

| Rusty Duramax Injector Lines

It's almost a shame the bright Bosch lines will be hidden once the external valve cover accessories are remounted.

| Duramax Filter Housing Install

Once the injector lines are in place, the fuel filter housing and FICM are reinstalled.

| Duramax Intake Install

The final step before starting the engine involves connecting the engine's air-intake tubing and filter box to the Duramax's turbocharger.

| Duramax Fuel Primer

Even with everything connected, the fuel system needs to be primed for the engine to start. This can be done by pressing on the primer on the filter housing, which, after about 20 to 30 pushes, will become hard, signaling it's time for the engine to be fired.

| Duramax Injector Good Balance Rates

With the Duramax started back up, the balance rates of the new injectors are checked and fall well within spec, and the LB7 is ready to hit the road for thousands more miles!

| Duramax Injector And Cup

Injector cups

Duramax injectors are not installed directly in the cylinder head. Instead, they're placed in injector cups that are then pressed into the head. These cups are just as difficult to access as the injectors themselves. A lot of people choose to replace the injector cups (which involves draining the coolant, then using a puller to remove them), as it usually only adds a few hours of additional labor. With replacing all eight injectors being a 12- to 14-hour job, it's cheap insurance.

| Duramax White Smoke

Diagnosing bad injectors on a 6.6L Duramax LB7 engine is usually pretty easy. The owner of this '03 Chevrolet Silverado 2500HD complained of white smoke coming from the tailpipe under load. As you can see, there's a whole lot of it when the engine is revved up. While white smoke can also indicate coolant bleeding past a blown head gasket, on an LB7 it usually means excess unburned fuel.

| Duramax White Smoke

Diagnosing bad injectors on a 6.6L Duramax LB7 engine is usually pretty easy. The owner of this '03 Chevrolet Silverado 2500HD complained of white smoke coming from the tailpipe under load. As you can see, there's a whole lot of it when the engine is revved up. While white smoke can also indicate coolant bleeding past a blown head gasket, on an LB7 it usually means excess unburned fuel.

| Duramax Injector Balance Rates

One sure way of testing the injectors is to check balance rates, which most diesel shops can do using a scan tool. Balance numbers of -5.8 and -6.5 on this truck showed the ECU was frantically trying to get fuel to lean cylinders to compensate for the bad injectors. A balance rate of -4 is considered the maximum allowable, while "good" is usually ± 2.

| Duramax Injector Balance Rates

One sure way of testing the injectors is to check balance rates, which most diesel shops can do using a scan tool. Balance numbers of -5.8 and -6.5 on this truck showed the ECU was frantically trying to get fuel to lean cylinders to compensate for the bad injectors. A balance rate of -4 is considered the maximum allowable, while "good" is usually ± 2.

| Duramax Intake Removal

Xtreme Diesel Inc's. owner, Jason Carrier, starts the procedure with a simple first step—removing the intake.

| Duramax Intake Removal

Xtreme Diesel Inc's. owner, Jason Carrier, starts the procedure with a simple first step—removing the intake.

| Duramax Filter Housing Removal

With the intake out of the way, next comes the fuel filter, housing, and lines. This assembly has to be removed in order to access the valve cover.

| Duramax Filter Housing Removal

With the intake out of the way, next comes the fuel filter, housing, and lines. This assembly has to be removed in order to access the valve cover.

| Duramax FICM Removal

Some computer hardware needs to be removed, as the fuel injection control module (FICM) is mounted on the passenger-side valve cover.

| Duramax FICM Removal

Some computer hardware needs to be removed, as the fuel injection control module (FICM) is mounted on the passenger-side valve cover.

| Duramax Computer Mount

Even with the main computer out of the way, its mount, as well as tons of rubber and electrical connections, also has to be temporarily relocated. Jason only removes exactly what he needs to minimize the possibility of a crossed hose or line during reassembly.

| Duramax Computer Mount

Even with the main computer out of the way, its mount, as well as tons of rubber and electrical connections, also has to be temporarily relocated. Jason only removes exactly what he needs to minimize the possibility of a crossed hose or line during reassembly.

| Duramax Injector Lines

This is the line from the common-rail to the injector line, which is finally exposed. Upper and lower valve covers still need to be removed in order to access the injectors.

| Duramax Injector Lines

This is the line from the common-rail to the injector line, which is finally exposed. Upper and lower valve covers still need to be removed in order to access the injectors.

| Duramax Upper Valve Cover

With the upper valve cover off, the LB7's valvetrain and injectors are finally exposed.

| Duramax Upper Valve Cover

With the upper valve cover off, the LB7's valvetrain and injectors are finally exposed.

| Duramax Injector Wires

Next, Jason removes the electrical connections to the injectors. Since these wires lead a very hard life, it's a good time to inspect them for any damage.

| Duramax Injector Wires

Next, Jason removes the electrical connections to the injectors. Since these wires lead a very hard life, it's a good time to inspect them for any damage.

| Duramax Lower Valve Cover

The lower valve cover can now be removed, which is one of the final steps before injector removal.

| Duramax Lower Valve Cover

The lower valve cover can now be removed, which is one of the final steps before injector removal.

| Duramax Injector Line

With the lower valve cover off, Jason then takes out the injector return line, being careful not to strip any of the bolts that secure it. Jason says these fasteners can be easily stripped during this process and must be replaced if that happens.

| Duramax Injector Line

With the lower valve cover off, Jason then takes out the injector return line, being careful not to strip any of the bolts that secure it. Jason says these fasteners can be easily stripped during this process and must be replaced if that happens.

| Pulling Duramax Injector

This is one of the few specialty tools needed for getting the extraction done—an injector puller. It's available at many tool supply trucks or stores, as well as online.

| Pulling Duramax Injector

This is one of the few specialty tools needed for getting the extraction done—an injector puller. It's available at many tool supply trucks or stores, as well as online.

| New Bosch Duramax Injector

After removing all four injectors on the passenger side of the engine, Jason is ready to install the new LB7 injectors. He says he only uses brand-new Bosch injectors, as he has seen other injectors fail in as little as 30,000 to 40,000 miles and have to be replaced (again).

| New Bosch Duramax Injector

After removing all four injectors on the passenger side of the engine, Jason is ready to install the new LB7 injectors. He says he only uses brand-new Bosch injectors, as he has seen other injectors fail in as little as 30,000 to 40,000 miles and have to be replaced (again).

| Duramax Injector Torque

After the injectors are placed in the injector cups, Jason secures the hold-downs with the recommended 37 ft-lb of torque.

| Duramax Injector Torque

After the injectors are placed in the injector cups, Jason secures the hold-downs with the recommended 37 ft-lb of torque.

| Duramax Return Line Install

With the new injectors in place, the reassembly process then begins, and it is basically the disassembly in reverse. First, the fuel rail is installed, along with new bolts (if needed.)

| Duramax Return Line Install

With the new injectors in place, the reassembly process then begins, and it is basically the disassembly in reverse. First, the fuel rail is installed, along with new bolts (if needed.)

| Lower Valve Cover On

With the new injectors, electrical connections, and lower valve cover reinstalled, it's now time to clean the upper valve cover and install it. Jason uses gray RTV silicone to ensure a leak-free seal between the head and the cover.

| Lower Valve Cover On

With the new injectors, electrical connections, and lower valve cover reinstalled, it's now time to clean the upper valve cover and install it. Jason uses gray RTV silicone to ensure a leak-free seal between the head and the cover.

| Upper Valve Cover On

| Upper Valve Cover On

| Duramax Bosch Injector Lines

After thousands of miles of hard use, the factory injector lines can often be contaminated with rust, as is the case here. In order to steer clear of wiping out a brand-new set of injectors, Jason always recommends replacing the injector lines with new Bosch pieces.

| Duramax Bosch Injector Lines

After thousands of miles of hard use, the factory injector lines can often be contaminated with rust, as is the case here. In order to steer clear of wiping out a brand-new set of injectors, Jason always recommends replacing the injector lines with new Bosch pieces.

| Rusty Duramax Injector Lines

It's almost a shame the bright Bosch lines will be hidden once the external valve cover accessories are remounted.

| Rusty Duramax Injector Lines

It's almost a shame the bright Bosch lines will be hidden once the external valve cover accessories are remounted.

| Duramax Filter Housing Install

Once the injector lines are in place, the fuel filter housing and FICM are reinstalled.

| Duramax Filter Housing Install

Once the injector lines are in place, the fuel filter housing and FICM are reinstalled.

| Duramax Intake Install

The final step before starting the engine involves connecting the engine's air-intake tubing and filter box to the Duramax's turbocharger.

| Duramax Intake Install

The final step before starting the engine involves connecting the engine's air-intake tubing and filter box to the Duramax's turbocharger.

| Duramax Fuel Primer

Even with everything connected, the fuel system needs to be primed for the engine to start. This can be done by pressing on the primer on the filter housing, which, after about 20 to 30 pushes, will become hard, signaling it's time for the engine to be fired.

| Duramax Fuel Primer

Even with everything connected, the fuel system needs to be primed for the engine to start. This can be done by pressing on the primer on the filter housing, which, after about 20 to 30 pushes, will become hard, signaling it's time for the engine to be fired.

| Duramax Injector Good Balance Rates

With the Duramax started back up, the balance rates of the new injectors are checked and fall well within spec, and the LB7 is ready to hit the road for thousands more miles!

| Duramax Injector Good Balance Rates

With the Duramax started back up, the balance rates of the new injectors are checked and fall well within spec, and the LB7 is ready to hit the road for thousands more miles!

| Duramax Injector And Cup

Injector cups

| Duramax Injector And Cup

Injector cups