| Stryker Injector Duration Module For 2013 To 2014 Ram 2500HD Front View

Our test mule for the TS Performance Stryker module was this 2013 Ram 2500 with just 6,800 miles on the odometer. A non-H.O. model, it came with the 370hp, 800-lb-ft-rated 6.7L Cummins and the 68RFE automatic transmission. The Ram dyno’d 312 hp and 695 lb-ft in stock form.

| Stryker Injector Duration Module For 2013 To 2014 Ram 2500HD Front View

Our test mule for the TS Performance Stryker module was this 2013 Ram 2500 with just 6,800 miles on the odometer. A non-H.O. model, it came with the 370hp, 800-lb-ft-rated 6.7L Cummins and the 68RFE automatic transmission. The Ram dyno’d 312 hp and 695 lb-ft in stock form.

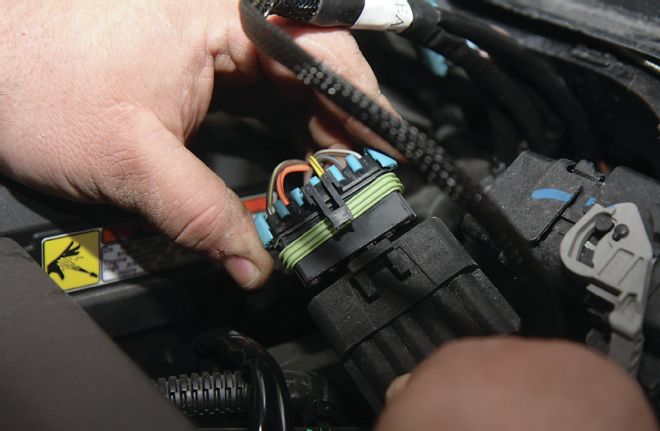

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Injector Harnesses

First things first, the guys at Randall’s Performance disconnected the battery terminals and made sure the key wasn’t in the ignition. Because the Stryker module connects inline with the injector harnesses on the engine, the injector harnesses were then located and unplugged.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Injector Harnesses

First things first, the guys at Randall’s Performance disconnected the battery terminals and made sure the key wasn’t in the ignition. Because the Stryker module connects inline with the injector harnesses on the engine, the injector harnesses were then located and unplugged.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Battery Terminals

To make installation as simple and fool-proof as possible, TS Performance labels which plug connects to the front and rear injector harness.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Battery Terminals

To make installation as simple and fool-proof as possible, TS Performance labels which plug connects to the front and rear injector harness.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Injector Harness

The guys at Randall’s started with the rear injector harness first. It’s as easy as disconnecting the factory wiring harness and connecting the supplied harness labeled “rear” to the connector that was just released. Then they moved on to the front harness.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Injector Harness

The guys at Randall’s started with the rear injector harness first. It’s as easy as disconnecting the factory wiring harness and connecting the supplied harness labeled “rear” to the connector that was just released. Then they moved on to the front harness.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD 06

After that, the harnesses that connect to the Stryker module were routed along the valve cover back to the firewall, and then forward along the driver-side front fenderwell. From there, the wiring harness was connected to the Stryker module itself. TS Performance supplies zip ties to secure the harness when routing it up to the module.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD 06

After that, the harnesses that connect to the Stryker module were routed along the valve cover back to the firewall, and then forward along the driver-side front fenderwell. From there, the wiring harness was connected to the Stryker module itself. TS Performance supplies zip ties to secure the harness when routing it up to the module.

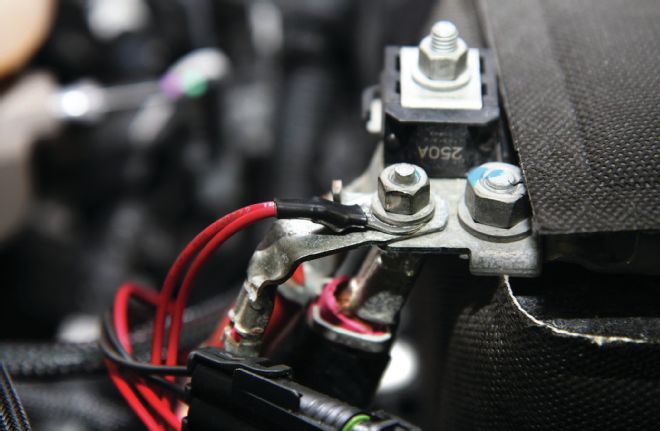

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Ground And Power Wire

In order to get power to the module, the ground and power wires were connected to the driver-side battery.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Ground And Power Wire

In order to get power to the module, the ground and power wires were connected to the driver-side battery.

| Stryker Injector Duration Module For 2013 To 2014 Ram Fuse Box Mount

Back on the rollers, the Ram picked up 4 pounds of boost under load (peaking at 33 psi), and EGT only increased by 50 degrees over stock (peaking at 1,200).

| Stryker Injector Duration Module For 2013 To 2014 Ram Fuse Box Mount

Back on the rollers, the Ram picked up 4 pounds of boost under load (peaking at 33 psi), and EGT only increased by 50 degrees over stock (peaking at 1,200).

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Module Mounted

With the module mounted, the wiring harness was given a once over to make sure it was out of harm’s way and all connection points were secure. Then the truck was fired up for the first time.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Module Mounted

With the module mounted, the wiring harness was given a once over to make sure it was out of harm’s way and all connection points were secure. Then the truck was fired up for the first time.

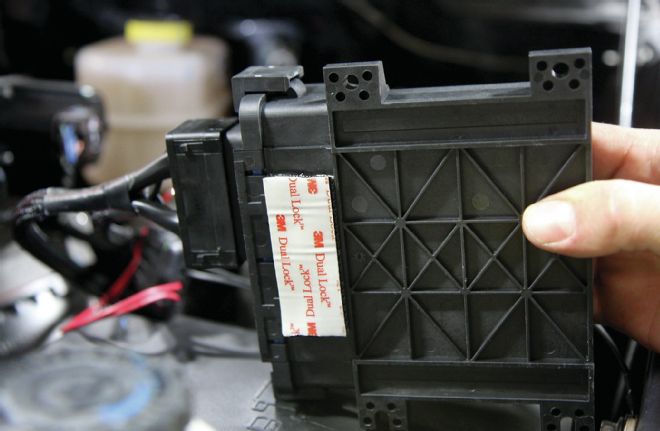

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Rear View On Dyno

We followed TS Performance’s recommendation of mounting the Stryker module on top of the fuse box (in front of the driver-side battery). However, the guys at Randall’s opted to Velcro it to the fuse box lid rather than secure it using the supplied zip ties.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Rear View On Dyno

We followed TS Performance’s recommendation of mounting the Stryker module on top of the fuse box (in front of the driver-side battery). However, the guys at Randall’s opted to Velcro it to the fuse box lid rather than secure it using the supplied zip ties.

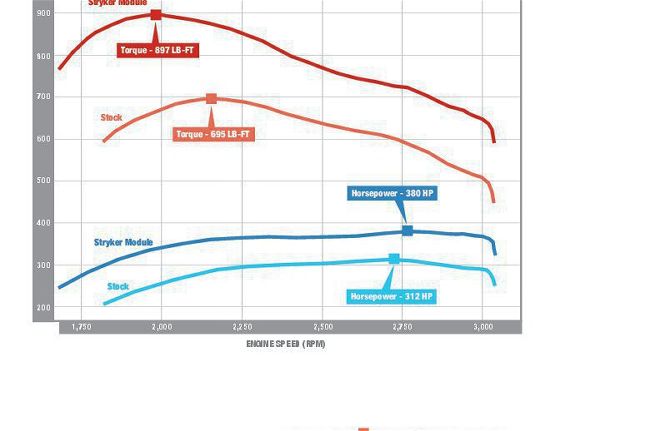

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Dyno Chart

When overlaying the stock dyno graph with the numbers made with the Stryker Injector Duration Module on the truck, you can see that significant gains were made. As for horsepower: from peak to peak, 68 hp was gained at the rear wheels (2,800 rpm), but at 1,800 rpm the truck is making at least 100 more hp than it did in stock form. As for torque: 250 lb-ft was gained at 1,800 rpm—right where it matters most. On top of that, gains of at least 150 lb-ft are seen throughout the duration of the graph, not to mention that nearly 900 lb-ft was achieved when the torque curve peaked at 2,000 rpm.

| Stryker Injector Duration Module For 2013 To 2014 Ram HD Dyno Chart

When overlaying the stock dyno graph with the numbers made with the Stryker Injector Duration Module on the truck, you can see that significant gains were made. As for horsepower: from peak to peak, 68 hp was gained at the rear wheels (2,800 rpm), but at 1,800 rpm the truck is making at least 100 more hp than it did in stock form. As for torque: 250 lb-ft was gained at 1,800 rpm—right where it matters most. On top of that, gains of at least 150 lb-ft are seen throughout the duration of the graph, not to mention that nearly 900 lb-ft was achieved when the torque curve peaked at 2,000 rpm.

*SuperFlow load-cell dyno

*SuperFlow correction factor

*Runs made in Fourth gear, from 50 to 90 mph

*25 percent load applied