| bosch Ve Fuel Pump Install injection Pump

When we bought our '89 Dodge, we found out during the long drive home that it had a top speed of about 75 mph. The horsepower was there, just not the rpms. When we put the truck on the dyno, our problem became even more obvious as we noticed our truck was pulling back fuel to the point where we only had about 50 horsepower at 80 mph. It was no wonder our truck felt so slow at highway speeds.

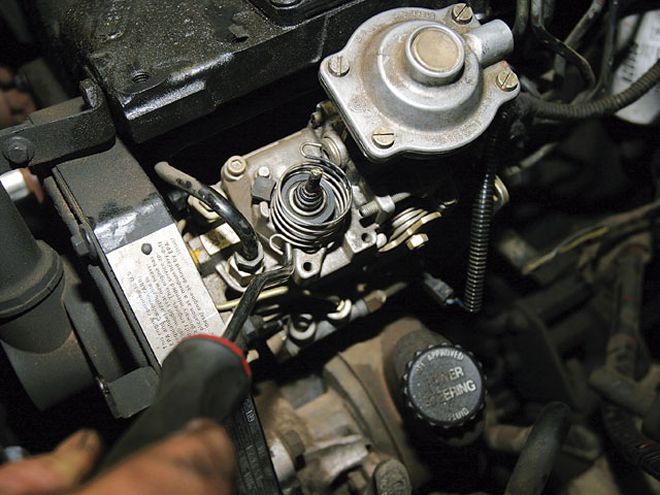

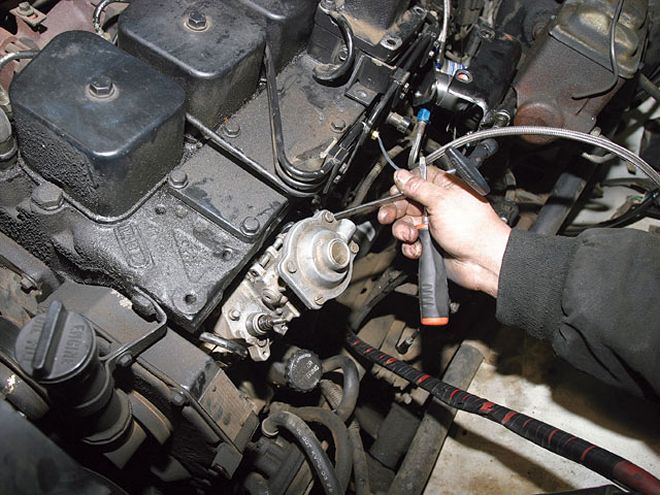

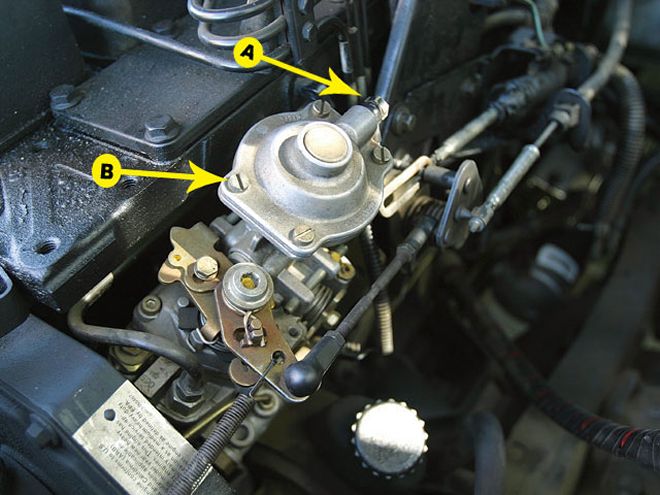

| Since we were first timers on this modification, we had Troy Chambers of J&H Performance walk us through the install. The first part of the governor spring installation involves removing the throttle linkage. Note the marks on the linkage so you can put everything back where you started once the spring is installed.

Interestingly enough, the solution to this limitation cost only $15.00. The Bosch VE injection pumps use a small spring (called a governor spring) that limits the fueling as revs rise, ultimately stopping at about 2,700 rpm. The solution is as simple as replacing the factory spring with a 3,200-rpm or 4,200-rpm governor spring, both available from many aftermarket sources. We went with the 3,200-rpm spring, as the 4,200-rpm spring can cause valve float unless you upgrade the stock valvesprings.

Since our truck came with a non-overdrive Torqueflite 727, we really needed the extra 500 rpm that this spring would give us. After we turned up the pump, our truck would top out at about 85 mph. The 3,200-rpm spring gave us a new theoretical top speed of about 97 mph, which meant we could now run it down the dragstrip! After the spring was installed, we took a few impromptu blasts down the highway, and verified that we had full fueling now up to about 75 mph before it would start to taper off. Before, even though we could go about 85 mph, it would start pulling fuel back at about 65 mph.

Now that we had a wider powerband, we wanted to increase our fueling over the entire rpm range. For this, we acquired a Power Pin from Dynomite Diesel, which would give us more fuel as boost came on. While the original fuel pin is cut on all sides, the aftermarket pin is cut only on one side. The cut face of the pin must be facing toward the front of the truck to work correctly; otherwise there will be no extra fuel as boost rises. With the governor spring in place and the pin installed, we were seeing 1-2 psi more boost than we had without the pin, which put us at about 33-34 psi. The truck hazed a little more black smoke down the road under full throttle, so we were hoping to see better numbers on the dyno. In order to free up any airflow restrictions that came with our fueling mods, we replaced the stock airbox and switched to a 4-inch exhaust. Check out how we performed these modifications and see if we made more power.

| bosch Ve Fuel Pump Install injection Pump

When we bought our '89 Dodge, we found out during the long drive home that it had a top speed of about 75 mph. The horsepower was there, just not the rpms. When we put the truck on the dyno, our problem became even more obvious as we noticed our truck was pulling back fuel to the point where we only had about 50 horsepower at 80 mph. It was no wonder our truck felt so slow at highway speeds.

| bosch Ve Fuel Pump Install injection Pump

When we bought our '89 Dodge, we found out during the long drive home that it had a top speed of about 75 mph. The horsepower was there, just not the rpms. When we put the truck on the dyno, our problem became even more obvious as we noticed our truck was pulling back fuel to the point where we only had about 50 horsepower at 80 mph. It was no wonder our truck felt so slow at highway speeds. | Since we were first timers on this modification, we had Troy Chambers of J&H Performance walk us through the install. The first part of the governor spring installation involves removing the throttle linkage. Note the marks on the linkage so you can put everything back where you started once the spring is installed.

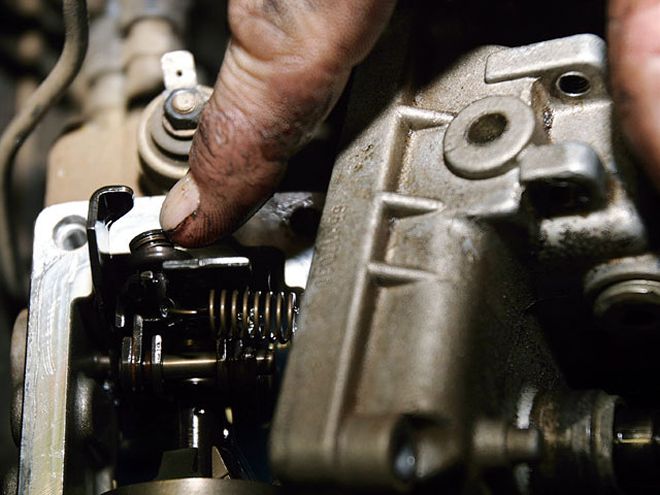

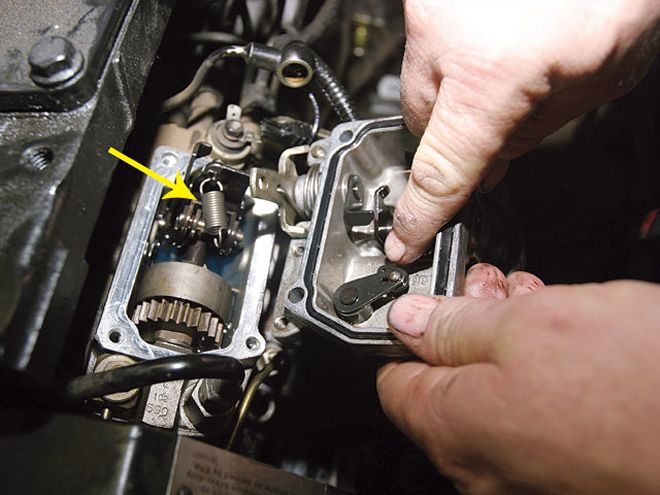

Interestingly enough, the solution to this limitation cost only $15.00. The Bosch VE injection pumps use a small spring (called a governor spring) that limits the fueling as revs rise, ultimately stopping at about 2,700 rpm. The solution is as simple as replacing the factory spring with a 3,200-rpm or 4,200-rpm governor spring, both available from many aftermarket sources. We went with the 3,200-rpm spring, as the 4,200-rpm spring can cause valve float unless you upgrade the stock valvesprings.

Since our truck came with a non-overdrive Torqueflite 727, we really needed the extra 500 rpm that this spring would give us. After we turned up the pump, our truck would top out at about 85 mph. The 3,200-rpm spring gave us a new theoretical top speed of about 97 mph, which meant we could now run it down the dragstrip! After the spring was installed, we took a few impromptu blasts down the highway, and verified that we had full fueling now up to about 75 mph before it would start to taper off. Before, even though we could go about 85 mph, it would start pulling fuel back at about 65 mph.

| Since we were first timers on this modification, we had Troy Chambers of J&H Performance walk us through the install. The first part of the governor spring installation involves removing the throttle linkage. Note the marks on the linkage so you can put everything back where you started once the spring is installed.

Interestingly enough, the solution to this limitation cost only $15.00. The Bosch VE injection pumps use a small spring (called a governor spring) that limits the fueling as revs rise, ultimately stopping at about 2,700 rpm. The solution is as simple as replacing the factory spring with a 3,200-rpm or 4,200-rpm governor spring, both available from many aftermarket sources. We went with the 3,200-rpm spring, as the 4,200-rpm spring can cause valve float unless you upgrade the stock valvesprings.

Since our truck came with a non-overdrive Torqueflite 727, we really needed the extra 500 rpm that this spring would give us. After we turned up the pump, our truck would top out at about 85 mph. The 3,200-rpm spring gave us a new theoretical top speed of about 97 mph, which meant we could now run it down the dragstrip! After the spring was installed, we took a few impromptu blasts down the highway, and verified that we had full fueling now up to about 75 mph before it would start to taper off. Before, even though we could go about 85 mph, it would start pulling fuel back at about 65 mph.