| time And Spark intake Stroke

Basic Four-Stroke EngineLets start with the piston at top dead center (TDC). In the first stroke in the cycle, known as the intake stroke, as the crank pulls the piston down, it also turns the cam; the cam opens up the intake valve, allowing the motor to suck the air/fuel mixture into the combustion chamber. As the crank continues to turn, the piston will then come back up. In the second stroke in the cycle, the cam closes the intake valve and the piston compresses the fuel in the combustion chamber (known as the compression stroke). This is where the ignition comes in: A spark of electricity arcs over the electrode on the spark plug, igniting the compressed fuel and creating an explosion. In the third stroke in the cycle, the kinetic energy from the burning fuel creates pressure in the cylinder, which forces the piston down; this is the combustion stroke. Completing the Four Stroke concept, in the fourth and final stroke in the cycle - labeled the exhaust stroke - this combustion forces the crank to carry the energy through the next rotation; the cam opens the exhaust valve, and as the piston returns to TDC, it evacuates the cylinder of the spent fuel.

How does the ignition know when to spark the fuel?Your basic ignition is really very simple. All the rotating components in your engine are tied together. This keeps the combination of components in time with one another. For example, in a pushrod motor, the crank is attached to the cam and the cam to the distributor. This is how the distributor knows which piston is coming up to TDC and which of these pistons is on the compression stroke. Each piston on the compression stroke gets sparked to ignite the compressed fuel at the optimal time.

How Does The Electricity Get To The Spark Plug?The distributor in a non-ECM-controlled engine performs three duties. First, it tells the coil when to release the high-voltage charge to the spark plug. Secondly, it carries the high-voltage charge to the cylinder on the compression stroke. Thirdly, it advances the timing to accommodate engine speed.

It does all this through the cam and internal spring and weight mechanism. The cam dictates which cycle a cylinder is on by way of opening and closing valves. It also spins the distributor shaft, which spins the rotor on top of it. As the cam closes the intake valve, and the piston comes up and compresses the fuel, the rotor aligns to the spark plug wire attached to the distributor cap.

Let's stop there for a moment. We're going to introduce the electricity here because of its relation to the spark of the plug. Mother Nature wants to balance everything out. Simply put, a battery has an abundance of positively charged electrons on one side and a lack of positively charged electrons on the other. Hence the negative (-) and positive (+) side on a battery. When connected together by a wire, the positively charged electrons will run to the negative side of the battery so fast that it will causes heat in the conduit. Without some sort of load, such as a light, which takes heat to make it operate, the movement of electrons will destroy the path wire from the heat. The battery will continue to flow electricity until both the positive and negative side of the battery become equal.

The coil is loaded with positively charged electrons and is ready to get rid of them. The spark plug is screwed into the head; therefore, it's grounded through the engine. This is another reason why it is important to make sure you have a good ground from the negative side of the battery to the block. As the rotor comes into alignment with the corresponding cap, wire, and plug, the positively charged electrons act on the path of least resistance; running through the cap and wire, then through the center of the spark plug. The voltage is so high that it physically jumps across the gap in the plug to reach the ground on the other side. This spark ignites the agitated, compressed fuel molecules in the chamber, creating the explosion.

When Should The Spark Ignite The Fuel?This is a seriously overlooked area when it comes to optimal tuning for power. It's not brain science, but there sure is a lot going on chemically. Fuel will only burn at a certain rate. Getting the combustion to release the majority of its power just as the piston starts its downstroke is crucial: too soon and the action will take place before the piston goes just beyond TDC, causing detonation and damage to the engine; too late and the combustion will not create optimal cylinder pressure and all the fuel won't burn. This will dramatically reduce the power and increase hydrocarbon emissions from not burning the fuel efficiently.

How Much Timing Do I Need?Ignition timing can be quite a feat considering most engines run at a variety of rpm, and a prime powerband can extend over a 2,500-rpm range. With the pistons moving at different speeds and the fuel burning at a constant rate, it's important to get the ignition timing to change. If you've ever shot a gun at a moving target, you know you have to shoot just in front of it so that the speed of the bullet and the speed of the object intersect at just the same time; this is known as lead. Timing advance has been referred to as lead, and essentially means the same thing, except you're leading the fuel burn for the piston speed. Variable timing is the only way to get the combustion to push on the top of the piston at the right time. In a 9.0:1 compression engine burning 87-octane gas, the optimal amount of total timing is 36 degrees. Total timing is the sum of the initial timing (where you set the distributor) plus the amount of advance in the distributor.

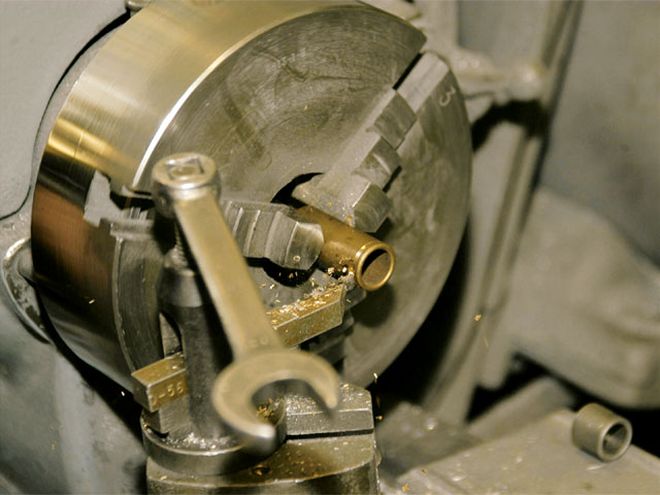

Some aftermarket distributors come with a range of spring and stops for a mechanical or vacuum advance to tailor the ignition curve to your application. But if you're not into guessing at it, Orange County Speed in Fullerton, California, can pretty much take care of the hit and miss. There is some basic information needed to get it right, but after the questions are answered, here's how the crew gets a distributor dialed.

| time And Spark intake Stroke

Basic Four-Stroke Engine

| time And Spark intake Stroke

Basic Four-Stroke Engine