| diesel Engine Cooling System adding Coolant

The purpose of the coolant (antifreeze or water) flowing through your diesel is to regulate the heat within the cylinder head and engine block that's created by the combustion process. In order to accomplish that job the coolant must be pumped around the engine compartment, pick up heat from the engine, transfer that heat into the radiator, all while limiting corrosion, lubricating the water pump, and not freezing.

Traditional antifreeze is a mixture that is 50 percent mix of ethylene glycol (EG) and 50 percent water. There are also propylene-glycol-based (PG) products on the market, and they have some different but interesting performance characteristics when compared to EG.

| If the proper coolant isn't used, corrosion, overheating, or water-pump failure could occur in your diesel engine.

Both ethylene glycol and propylene glycol fall into the glycols family that is much larger than the two formulations mentioned. Glycol is used in various forms not only as antifreeze but also in resin formulations, plastics, solvents, fertilizer, food products, shaving cream, chemical production, and as an airplane deicer.

In most instances the ethylene glycol and propylene glycol base are not produced by the company that is selling the antifreeze; it's purchased from manufacturers such as the Dow Chemical Corporation. When ethylene glycol is used as a coolant, the exact formulation of additives is what defines the difference in brands.

Vapor Pressure And Boiling Point All liquids create vapors. The amount of vapor produced is defined by the chemical characteristics of the liquid. The pressure exerted by these vapors in the presence of the liquid is defined as vapor pressure. Vapor pressure increases as the temperature is elevated.

The boiling point of a liquid is defined as the temperature at which the vapor pressure is equal to the external pressure on the surface of the liquid. When a liquid is heated in an open vessel it will boil when its vapor pressure is equal to the atmospheric pressure. Keeping this in mind, as elevation is increased the atmospheric pressure decreases and the boiling point of a liquid is lowered. Back in the early days it was common for an engine to "boil over" when carrying a heavy load in high elevations like those found in the mountains out West. The early cooling systems were not pressurized, so increases in altitude were very problematic. The use of a pressure cap raises the boiling point of the coolant 3 degrees Fahrenheit for every psi of pressure over atmospheric.

Ethylene glycol and propylene glycol have lower vapor pressures than water, and their boiling points are higher than water. Glycols are considered high-boiling-point liquids because of their low vapor pressure. As an example, at 68 degrees the vapor pressure of water is more than 100 times greater that that of propylene glycol. The low volatility of glycols lessens their tendency to evaporate and has led to their use as antifreeze for engines.

Glycol/water mixes generally have physical properties between those of water and plain glycols. The addition of water to ethylene glycol lowers its boiling point over that of straight EG. The smaller the concentrate of EG, the lower the boiling point will be.

Distilled And Deionized WaterIf a traditional EG-based coolant is going to be used, it needs to be mixed with water to become an effective heat transfer medium. The proper procedure is to use either distilled or deionized water and not tap water. This leads to much confusion since many do not understand what makes water either distilled or deionized.

The water supplied by most city water departments contains some dissolved solids that cause scale deposits as well as corrosive ions, such as chlorides and sulfates, when used as a coolant. Although these elements are usually soluble in water, they can attack the cooling system. Water taken from wells can be especially high in mineral content.

The best water to use, according to the Dow Chemical Company (makers of EG and PG), has been distilled and deionized or passed through a reverse osmosis process to remove minerals and salts.

The Boiling RegimenWhen it comes to boiling, it's true that it's not desirable to have this occur in the radiator. The radiator's job is to cool the liquid, while the liquid's task is to cool the engine. If the radiator of an engine is boiling over, the coolant is becoming super heated and starts turning into vapor. When it recondenses, it contains too much heat for the radiator to dissipate. So, as you can see, we need to identify when and where it's good to have the coolant boil.

The load on the cooling system and the coolant itself isn't the same under all driving conditions. At idle and light load, such as cruising on the highway, the engine isn't required to produce much power. Since a diesel engine is nothing more than a heat pump, the thermal load the liquid coolant is exposed to is proportional to the heat of the power produced. When climbing a long grade, pulling a trailer, or producing maximum power, the load on the coolant increases. The coolant must work to meet the transient needs of the engine.

Traditional antifreeze that's a mix of EG and water solves some of the problems but brings along its own set of issues. Water by itself has a very high surface tension, and when it does boil it's hard for it to release and recondense back to a liquid and remove heat from the boiling-point location. In simple terms, it's advantageous for the coolant to boil in the cylinder head, but it needs to refrain from undergoing a phase change for as long as possible for it to be the most effective. Then it must release easily so it can move from that spot and take heat with it. Then it's required to recondense quickly.

Once it enters the radiator, it must possess enough thermal dissipation to cool and be ready for the entire event again. An engine that is loafing for most of its life and hardly ever has the coolant work hard will have the additives stay active longer. This is not to be confused with the freeze point. That doesn't change as the additives are depleted. For this reason, if traditional EG-based coolants are used, they need to be changed on a regular basis. The recommendation of a maximum of three years is only for an engine that sees normal duty. In severe usage, such as racing or towing, the coolant would need to be changed more frequently.

Evans Cooling Systems has developed its NPG+ coolant that has a lower surface tension than EG/water, boils at 369 degrees at atmospheric pressure, and allows the coolant to remove more heat from the cylinder head. It also eliminates all water and the possibility of corrosion and cylinder liner cavitation. In addition, it's a lifetime coolant that will perform for 300,000 miles with no need to introduce any SCA.

Even with a 15-psi pressure cap, water will boil at 257 degrees (water/EG will boil at 264 degrees at 15 psi), giving the Evans product an advantage of 105 degrees. When choosing a coolant for a diesel engine you need to consider the worst-case conditions, not idle or light load. Current EG/water mixes, though the standard, are inferior when the load/horsepower of the engine increases.

Good MaintenanceA high-powered diesel engine is very hard on the coolant. Additive-depleted coolant will not only allow liner cavitation but cause premature failure of the head gaskets, radiator, water pump, freeze plugs, heater core and thermostat. This is especially a concern when purchasing a used diesel truck. Often, the cooling system hasn't been serviced properly.

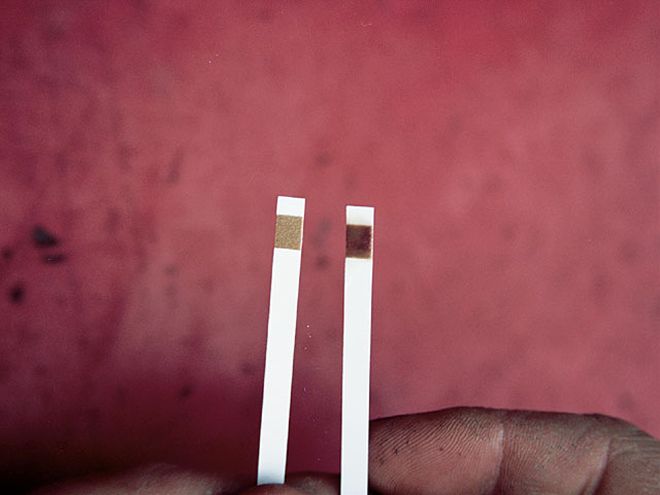

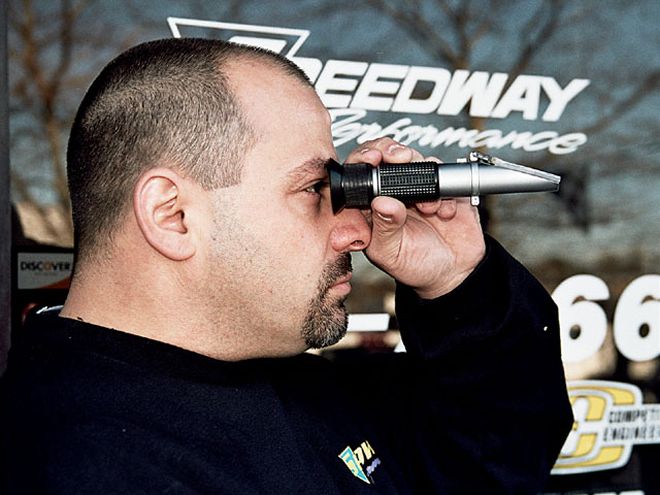

Since diesel engines have such a large liquid capacity, cooling system test strips are offered to check the level of additives. If the level is low, a bottle of SCA can be mixed in to renew the coolant without a complete change. Checking the additive level should be part of an established maintenance schedule.

When it comes time to buy coolant, make sure it's compatible with a diesel engine, not automotive/light-truck use, which means gasoline powered. If a switch to a product such as the Evans NPG+ is not in your plans, always reference the vehicle owner's manual for the proper coolant, usually identified by its color.

| diesel Engine Cooling System adding Coolant

The purpose of the coolant (antifreeze or water) flowing through your diesel is to regulate the heat within the cylinder head and engine block that's created by the combustion process. In order to accomplish that job the coolant must be pumped around the engine compartment, pick up heat from the engine, transfer that heat into the radiator, all while limiting corrosion, lubricating the water pump, and not freezing.

Traditional antifreeze is a mixture that is 50 percent mix of ethylene glycol (EG) and 50 percent water. There are also propylene-glycol-based (PG) products on the market, and they have some different but interesting performance characteristics when compared to EG.

| diesel Engine Cooling System adding Coolant

The purpose of the coolant (antifreeze or water) flowing through your diesel is to regulate the heat within the cylinder head and engine block that's created by the combustion process. In order to accomplish that job the coolant must be pumped around the engine compartment, pick up heat from the engine, transfer that heat into the radiator, all while limiting corrosion, lubricating the water pump, and not freezing.

Traditional antifreeze is a mixture that is 50 percent mix of ethylene glycol (EG) and 50 percent water. There are also propylene-glycol-based (PG) products on the market, and they have some different but interesting performance characteristics when compared to EG.

| If the proper coolant isn't used, corrosion, overheating, or water-pump failure could occur in your diesel engine.

Both ethylene glycol and propylene glycol fall into the glycols family that is much larger than the two formulations mentioned. Glycol is used in various forms not only as antifreeze but also in resin formulations, plastics, solvents, fertilizer, food products, shaving cream, chemical production, and as an airplane deicer.

In most instances the ethylene glycol and propylene glycol base are not produced by the company that is selling the antifreeze; it's purchased from manufacturers such as the Dow Chemical Corporation. When ethylene glycol is used as a coolant, the exact formulation of additives is what defines the difference in brands.

Vapor Pressure And Boiling Point

| If the proper coolant isn't used, corrosion, overheating, or water-pump failure could occur in your diesel engine.

Both ethylene glycol and propylene glycol fall into the glycols family that is much larger than the two formulations mentioned. Glycol is used in various forms not only as antifreeze but also in resin formulations, plastics, solvents, fertilizer, food products, shaving cream, chemical production, and as an airplane deicer.

In most instances the ethylene glycol and propylene glycol base are not produced by the company that is selling the antifreeze; it's purchased from manufacturers such as the Dow Chemical Corporation. When ethylene glycol is used as a coolant, the exact formulation of additives is what defines the difference in brands.

Vapor Pressure And Boiling Point