First Generation Vortec 350 Power Upgrades - Pop-It Valve Power

GM's first-generation Vortec engine was derived from its fuel-injected predecessor, the throttle-body fuel injection (TBI). Both the TBI and Vortec engines used only two injectors to supply fuel to the 350ci V-8. The differences between them are that the TBI had the injectors right in front of the throttle plate, where the Vortec placed the injectors behind the throttle plate; and the TBI was a speed density system, whereas the Vortec used a mass airflow system to manage the fuel-injection system.

Even though changing the fuel-injection system to a newer mass airflow system was an improvement, it still carried some faults. With the injectors moved out of the air stream, the engine can pull more air, but the two injectors still can't supply or distribute the fuel as efficiently as true direct port injection. The first-generation Vortec was GM's early attempt at an inexpensive port injection system.

The Vortec's two injectors spray fuel into a distribution block. This block has eight plastic hoses attached to it that carry the fuel to the end of each intake runner. At the end of each plastic hose is a spring-loaded check valve known as a pop-it valve. These pop-it valves open when the injectors pressurize the fuel block and hoses. The run on the Vortec 350 engine was relatively short: It hit the market in 1996 and was replaced with GM's new-generation engine line by 1999.

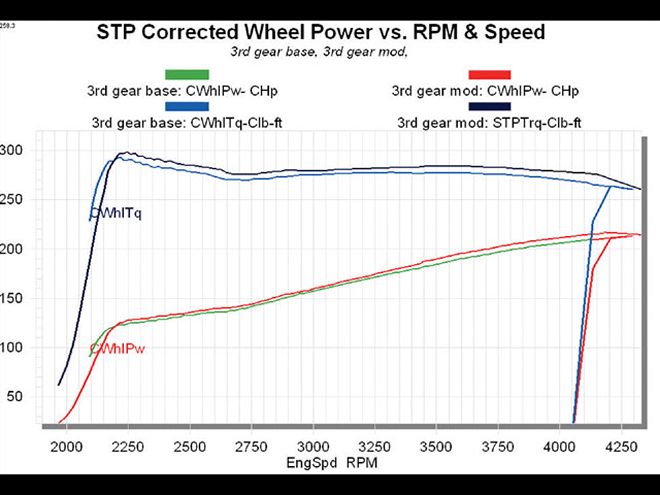

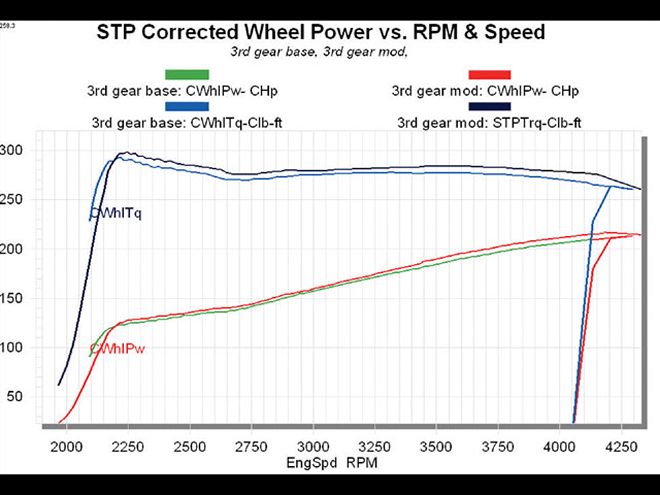

Due to the short duration and its limited-performance injection system, not many aftermarket companies spent the time or money making performance parts for the Vortec fuel-injected 350 engines. But, of course, that doesn't completely eliminate it from modifications. In fact, we found your typical filters, intakes, exhaust, and even big-mouth throttle bodies. We contacted Gibson for its dual stainless exhaust system, BBK for a high-flow throttle body and spacer, and Airad for a cotton-gauze filter to see how much power was left on the table. We dyno'd the engine and gained 9 hp and 12 lb-ft. You can see the dynamometer results: The upgrades follow the engine's powerband, but at higher power numbers.

Of course, you can't just buy parts and expect that they will give you great results. Every situation is different and this one had some basic fuel issues. The stock dyno pulls averaged a 12.12:1 air/fuel ratio, which showed that the stock programming with the stock components is really close to perfect. The performance upgrades are definitely holding up to their claims. After adding the mods, we found that the air/fuel ratio went to an average of 14.4:1, which is way too lean. Even though we find that the performance upgrades provided an increase in power, we know that there is much more to be had with a programmer that would enhance the fuel to accommodate the increased airflow.

| valve Power stp Corrected Wheel Power

Dyno Results+12 LB-FT of torque

+9 horsepower

As far as the filter from Airad, it was the first modification completed and was already installed before we started this project, although we did clean it.

| valve Power stp Corrected Wheel Power

Dyno Results

| valve Power stp Corrected Wheel Power

Dyno Results