| diesel Performance Modifications intake

There is a dizzying array of aftermarket products available today for the diesel enthusiast. From the mundane to the exotic, there are products being engineered that can deliver unbelievable performance and add to the power and efficiency of your vehicle. Sometimes, it's hard to know how to narrow down the options, or even just where to start. So, if you want to know how to spend your first $50, your first $100, or even your first $1,000, you've come to the right place. Our list won't work for every single diesel owner out there. But, it's what we'd tell you to do if you were, say, our brother's neighbor's boss who just bought a new diesel truck and wanted to make it run stronger. Take a look.

| diesel Performance Modifications exhaust

The stock exhaust on your truck uses small-diameter pipe, typically with some odd bends and pinches, which, combined, make it difficult for the engine to push the exhaust gases through quickly and easily. A good aftermarket exhaust uses larger diameter pipe (typically between 3-1/2 and 5 inches outside diameter) with as few bends and turns as possible to exit these gases more efficiently.

A high-flow exhaust system provides a number of benefits. The first, of course, is better sound. Plus, with better breathing comes the ability to support improved horsepower and torque. This system will also aid in keeping the exhaust gas temperature (EGT) down, which adds to overall performance and will help extend the life of your engine.

If your plans include performance upgrades like computer chips, electronic programmers, or turbocharger modifications, then a high-flow exhaust is essential. These types of upgrades are designed to recalibrate the air/fuel mixture in your engine to produce more power. And while they can do wonders for overall performance, they also create more heat and exhaust gas than the stock exhaust system is designed to deal with effectively. As with any engine, heat is bad. Heat will kill performance, and over the long run, it will kill your engine. So, go to a high-flow exhaust. You'll breathe easier.

| diesel Performance Modifications programmer

The performance parameters of modern vehicles are governed almost exclusively by that little black box called the electronic control module (ECM). Within this electronic monster lay endless lines of computer code that direct all the electronic functions on your truck. Not surprisingly, original equipment (OE) engineers have to calibrate the engine to less than their true potential. This is done to meet durability, emissions (set by our government), and fuel economy requirements-leaving lots of fun and power tightly locked away.

One of the most effective ways to unlock the hidden potential in your truck is with an aftermarket computer calibration from modules that essentially rewrite the rules your truck plays by. Typically, they adjust the amount (as well as timing and pressure) of fuel that is injected into the cylinder to increase performance. Turbo boost pressure and transmission shifting may also be altered for noticeable improvements in overall performance. For vehicles without removable chips, you can simply pull the ECM out of your truck and have it re-programmed to optimize the fuel and timing curves throughout the entire powerband. Either way, previously untapped torque and horsepower await.

For those who enjoy tweaking their own engines, there is a wide range of programmers on the market that allow you to program the computer yourself. The best ones come with software that walks you through the process and explains each action as you go along. Often, these programmers also include a built-in scan tool that will read and clear diagnostic codes.

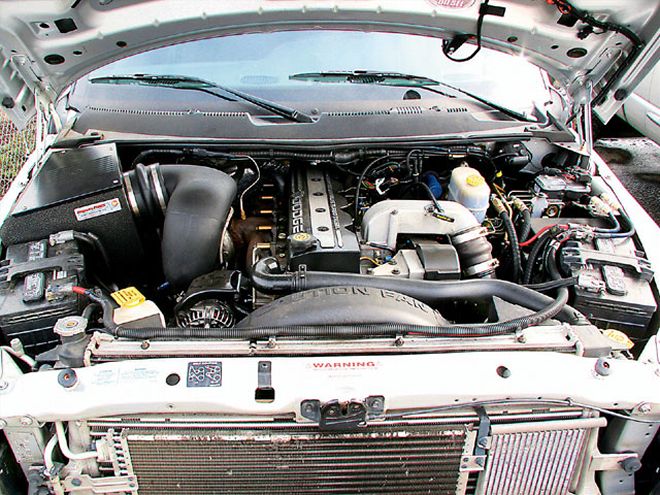

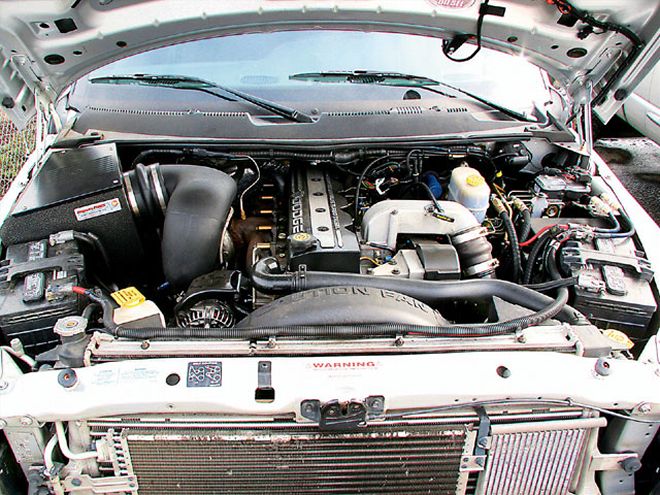

| diesel Performance Modifications cold Air Intake

All diesel engines require unimpeded airflow to perform at their best. Quite simply, the more air you can flow through an engine, the more oxygen will be available for burning fuel, and the more power you will make.

The stock air intake on your truck typically restricts airflow in two ways. First is the design of the intake box itself. Most trucks use an air inlet that draws in air from either the inner fender or the radiator bulkhead to meet the manufacturer's standards for induction and drive-by noise. This can dramatically limit the flow of fresh air to the engine. Second is the high-capacity paper filter element inside the box, which tends to slow the flow of air streaming into the intake even further.

Fortunately, this is an easy fix. There are any number of aftermarket companies now that offer complete air intake kits that replace the entire airbox with a high-flow system. These typically include an oiled, cotton-gauze (or synthetic) filter that, even when filthy, will flow more air than the paper element ever could. This upgrade will translate to better air/fuel ratios, greater engine efficiency, and more usable horsepower and torque. This is a simple upgrade and one that you will feel immediately. Throttle response will be sharper, and your gas mileage should go up just a bit.

| diesel Performance Modifications gauges

As you sit around daydreaming about all the great upgrades you have planned for your truck, gauges may rank low on the list. But, remember, most of the modifications you make to your diesel will cause it to produce more power and place greater demands on your vehicle's systems. Well-designed gauges will give you a good jump on any problems that could arise.

There are few things that will destroy your engine faster than excessive exhaust gas temperature (EGT). So, at the top of the gauge list should be a pyrometer. This gauge will monitor EGT levels and give you advanced warning of anything dire. This gauge comes with a thermocouple probe that can either be installed on the exhaust manifold or behind the turbine outlet on the turbocharger. It's up to you, but we recommend removing the turbo and drilling the manifold for the most accurate numbers.

Next up would be a boost gauge, which is used to monitor turbocharger performance. High-end models will allow you to target your ideal boost setting and reconfigure it according to your engine specifications.

Many gearheads disregard it, but transmission temperature should be monitored along with everything else on your truck. Once you know the standard operating temperature of your transmission, it's easy to glance at the gauge occasionally to make sure everything is running smoothly. A blown transmission is an expensive repair, and a simple little gauge could go a long way toward extending its life.

| diesel Performance Modifications torque Converter

As you go about the process of turning your diesel truck into a high-performance machine with gut-wrenching torque and horsepower, it's easy to forget about the transmission. You don't look at it every day (it's not particularly sexy), and you wouldn't think it would make you go any faster. However, if you abuse it enough, it does have the ability to slow you down and even bring you to a grinding halt.

The stock transmission in your truck is designed for stock power output-or something close-when towing at maximum gross combined weight rating (GCWR). But, by the time you upgrade your turbo, add propane injection, stack on a couple of computer modules, and do some high-end tuning, you've left that transmission far behind-hopefully, not literally. That's why turning to an aftermarket transmission or opting to have your own rebuilt makes a lot of sense. Transmissions built for extreme duty have a number of things in common. They are usually equipped with more clutch plates to handle heavy loads and high horsepower. These extra clutches prevent slippage when the transmission shifts. Some of these transmissions also include high-performance valvebodies to provide increased line pressures and improved ATF flow through the coolers, which results in better shift quality and extended life.

Torque converters also take their fair share of abuse. With enough horsepower, torque, and load, the clutch inside the converter can start to slip, which results in friction and heat. Ultimately, the converter can deform and self-destruct. High-performance converters are typically built using a billet steel shell to better withstand heat and abuse, and they are designed with multiple clutch discs that significantly increase the converter's clutch-holding power.

| diesel Performance Modifications turbo

The theory behind turbochargers is simple: The more air you can force into an engine, the more power it will make. A turbocharger uses a turbine, which is driven by exhaust gases, and a compressor, which pressurizes the intake, to force-feed air to the engine and dramatically increase engine performance. The amount of air created by the turbo is generally referred to in terms of boost measured in pounds per square inch (psi).

Your factory turbo-assuming you have one-is designed to supply your diesel with typically two to three times the amount of air it would otherwise draw in. You need air to burn diesel fuel, but now that you've added a programmer, box, or performance calibration, chances are good you have more fuel than your engine can burn. The result is black smoke, high EGT, and poor fuel economy. Your engine needs more air. It's time for a turbo upgrade.

You might be tempted to think the bigger the turbo the better. And that's true to a certain point. Many companies offer larger turbos for the popular applications. Bigger turbos generally produce more total boost, but they also take longer to get there-and tend to provide less boost at lower engine speeds, where your engine spends most of time. Ball bearing turbos can increase boost and spool up quick, thanks to their low internal drag.

This dilemma of big boost versus turbo lag has caused some diesel owners to go with twin-turbo systems. With two turbochargers working in tandem, you can get the benefits of a quick spooling (small) turbo and the benefits of a (large) performance turbo. For Diesel Power enthusiasts, this is the ultimate because of the incredibly quick spool-up times and the sheer amount of boost created.

| diesel Performance Modifications injectors

Now that you've added more fuel with computer tricks and improved your engine's ability to pump air, it may be time to look into a new set of injectors. With diesel engines, the role of the injectors in overall performance can be huge. The aftermarket offers performance injectors that are typically based on stock units that are reworked to flow more fuel at a given setting. The key here is to match the injector with your usage. Typically, injectors are rated for horsepower levels. The amount of diesel fuel required to support a particular power level can be calculated. And in a perfect world you want injectors that won't be overkill for your application yet aren't maxed out either. Like most things in life, injectors have a sweet spot where they work best.

Some performance enthusiasts like running an auxiliary electric lift pump as insurance to protect the injection pump, usually at the least opportune time. Some truck owners turn to aftermarket lift pumps out of sheer necessity. Duramax owners should consider an electric lift pump at anything above stock power levels because these trucks don't have lift pumps at all.

At best, the stock lift pump is designed to provide fuel delivery for a stock engine. Once you begin adding the kinds of aftermarket upgrades we've been talking about, the demand for fuel goes up, too. The stock lift pump quickly falls short. Fluctuations in performance at higher rpm and engine load will signal it's time for an upgrade.

In a turbodiesel engine system, the intercooler is designed to do one thing: Cool the air after it leaves the turbocharger and before it reaches the engine. Sometimes called charge-air cooling, this process has tremendous impact on engine performance. As pressurized air passes through the intercooler from the turbocharger, the temperature of the air drops and it becomes more dense. Cooler, denser air allows greater amounts of fuel to be burned, which means greater horsepower. Cooler, denser air also means lower exhaust gas temperature (EGT), which allows the engine to perform even more efficiently.

Basically, an intercooler is a heat exchanger. And as with all heat exchangers, the greater the surface area, the more efficiently it cools. Stock intercoolers are fine for stock applications. But, as you expand the performance attributes of your truck, the stock unit may not keep up. Most aftermarket intercoolers are one-piece, aluminum, fin-type models with inlets and outlets that are much larger than stock to provide greater flow of air. Using ambient air flowing through the grille and radiator, a high-performance intercooler will dramatically lower the temperature of the boost intake air and contribute to optimal engine performance. So whether you are converting to a turbo setup or swapping in a bigger turbo, don't shortchange on your intercooler. It's one of the best improvements you'll make.

| diesel Performance Modifications nitrous

Another option for pulling more power from turbodiesels is nitrous oxide injection. When nitrous is injected into the intake air, the heat of compression breaks the molecules down into nitrogen and oxygen. It is this extra oxygen burst that allows the engine to burn greater amounts of diesel fuel. The more air you can pack into the combustion chamber, the more fuel you can burn, and the more power you can produce. Nitrous is literally like a turbocharger in a bottle. Naturally, though, all systems have their limits, and then fun ends when the bottle runs out.

For heavy-duty tow rigs and street racers, this might well be the final power upgrade. Often referred to as chemical intercooling, water/methanol injection provides big gains in power with cooler combustion temperatures. Running a 50/50 water/methanol mix, it's typical to see gains of 70-plus horsepower, 100-plus lb-ft of torque, and 3 to 5 psi of boost, all with a decrease of 200-plus degrees in exhaust gas temperature.

The science behind this technology has been around for decades, and the mix has long been popular with drag racers. Basically, a high-pressure pump injects the water/methanol mixture into the intake plenum. Small nozzles spray in the juice as the turbo boost level comes up. Usually, an electronic controller meters out the amount of water/methanol so that it remains proportional to boost levels. The burst of speed you get as you drop the hammer is considerable. And it's perfect for lowering EGT when pulling heavy loads up steep inclines or simply enjoying the wow-factor on the quarter-mile.

| diesel Performance Modifications intake

There is a dizzying array of aftermarket products available today for the diesel enthusiast. From the mundane to the exotic, there are products being engineered that can deliver unbelievable performance and add to the power and efficiency of your vehicle. Sometimes, it's hard to know how to narrow down the options, or even just where to start. So, if you want to know how to spend your first $50, your first $100, or even your first $1,000, you've come to the right place. Our list won't work for every single diesel owner out there. But, it's what we'd tell you to do if you were, say, our brother's neighbor's boss who just bought a new diesel truck and wanted to make it run stronger. Take a look.

| diesel Performance Modifications intake

There is a dizzying array of aftermarket products available today for the diesel enthusiast. From the mundane to the exotic, there are products being engineered that can deliver unbelievable performance and add to the power and efficiency of your vehicle. Sometimes, it's hard to know how to narrow down the options, or even just where to start. So, if you want to know how to spend your first $50, your first $100, or even your first $1,000, you've come to the right place. Our list won't work for every single diesel owner out there. But, it's what we'd tell you to do if you were, say, our brother's neighbor's boss who just bought a new diesel truck and wanted to make it run stronger. Take a look.

| diesel Performance Modifications exhaust

The stock exhaust on your truck uses small-diameter pipe, typically with some odd bends and pinches, which, combined, make it difficult for the engine to push the exhaust gases through quickly and easily. A good aftermarket exhaust uses larger diameter pipe (typically between 3-1/2 and 5 inches outside diameter) with as few bends and turns as possible to exit these gases more efficiently.

A high-flow exhaust system provides a number of benefits. The first, of course, is better sound. Plus, with better breathing comes the ability to support improved horsepower and torque. This system will also aid in keeping the exhaust gas temperature (EGT) down, which adds to overall performance and will help extend the life of your engine.

If your plans include performance upgrades like computer chips, electronic programmers, or turbocharger modifications, then a high-flow exhaust is essential. These types of upgrades are designed to recalibrate the air/fuel mixture in your engine to produce more power. And while they can do wonders for overall performance, they also create more heat and exhaust gas than the stock exhaust system is designed to deal with effectively. As with any engine, heat is bad. Heat will kill performance, and over the long run, it will kill your engine. So, go to a high-flow exhaust. You'll breathe easier.

| diesel Performance Modifications exhaust

The stock exhaust on your truck uses small-diameter pipe, typically with some odd bends and pinches, which, combined, make it difficult for the engine to push the exhaust gases through quickly and easily. A good aftermarket exhaust uses larger diameter pipe (typically between 3-1/2 and 5 inches outside diameter) with as few bends and turns as possible to exit these gases more efficiently.

A high-flow exhaust system provides a number of benefits. The first, of course, is better sound. Plus, with better breathing comes the ability to support improved horsepower and torque. This system will also aid in keeping the exhaust gas temperature (EGT) down, which adds to overall performance and will help extend the life of your engine.

If your plans include performance upgrades like computer chips, electronic programmers, or turbocharger modifications, then a high-flow exhaust is essential. These types of upgrades are designed to recalibrate the air/fuel mixture in your engine to produce more power. And while they can do wonders for overall performance, they also create more heat and exhaust gas than the stock exhaust system is designed to deal with effectively. As with any engine, heat is bad. Heat will kill performance, and over the long run, it will kill your engine. So, go to a high-flow exhaust. You'll breathe easier.

| diesel Performance Modifications programmer

The performance parameters of modern vehicles are governed almost exclusively by that little black box called the electronic control module (ECM). Within this electronic monster lay endless lines of computer code that direct all the electronic functions on your truck. Not surprisingly, original equipment (OE) engineers have to calibrate the engine to less than their true potential. This is done to meet durability, emissions (set by our government), and fuel economy requirements-leaving lots of fun and power tightly locked away.

One of the most effective ways to unlock the hidden potential in your truck is with an aftermarket computer calibration from modules that essentially rewrite the rules your truck plays by. Typically, they adjust the amount (as well as timing and pressure) of fuel that is injected into the cylinder to increase performance. Turbo boost pressure and transmission shifting may also be altered for noticeable improvements in overall performance. For vehicles without removable chips, you can simply pull the ECM out of your truck and have it re-programmed to optimize the fuel and timing curves throughout the entire powerband. Either way, previously untapped torque and horsepower await.

For those who enjoy tweaking their own engines, there is a wide range of programmers on the market that allow you to program the computer yourself. The best ones come with software that walks you through the process and explains each action as you go along. Often, these programmers also include a built-in scan tool that will read and clear diagnostic codes.

| diesel Performance Modifications programmer

The performance parameters of modern vehicles are governed almost exclusively by that little black box called the electronic control module (ECM). Within this electronic monster lay endless lines of computer code that direct all the electronic functions on your truck. Not surprisingly, original equipment (OE) engineers have to calibrate the engine to less than their true potential. This is done to meet durability, emissions (set by our government), and fuel economy requirements-leaving lots of fun and power tightly locked away.

One of the most effective ways to unlock the hidden potential in your truck is with an aftermarket computer calibration from modules that essentially rewrite the rules your truck plays by. Typically, they adjust the amount (as well as timing and pressure) of fuel that is injected into the cylinder to increase performance. Turbo boost pressure and transmission shifting may also be altered for noticeable improvements in overall performance. For vehicles without removable chips, you can simply pull the ECM out of your truck and have it re-programmed to optimize the fuel and timing curves throughout the entire powerband. Either way, previously untapped torque and horsepower await.

For those who enjoy tweaking their own engines, there is a wide range of programmers on the market that allow you to program the computer yourself. The best ones come with software that walks you through the process and explains each action as you go along. Often, these programmers also include a built-in scan tool that will read and clear diagnostic codes.

| diesel Performance Modifications cold Air Intake

All diesel engines require unimpeded airflow to perform at their best. Quite simply, the more air you can flow through an engine, the more oxygen will be available for burning fuel, and the more power you will make.

The stock air intake on your truck typically restricts airflow in two ways. First is the design of the intake box itself. Most trucks use an air inlet that draws in air from either the inner fender or the radiator bulkhead to meet the manufacturer's standards for induction and drive-by noise. This can dramatically limit the flow of fresh air to the engine. Second is the high-capacity paper filter element inside the box, which tends to slow the flow of air streaming into the intake even further.

Fortunately, this is an easy fix. There are any number of aftermarket companies now that offer complete air intake kits that replace the entire airbox with a high-flow system. These typically include an oiled, cotton-gauze (or synthetic) filter that, even when filthy, will flow more air than the paper element ever could. This upgrade will translate to better air/fuel ratios, greater engine efficiency, and more usable horsepower and torque. This is a simple upgrade and one that you will feel immediately. Throttle response will be sharper, and your gas mileage should go up just a bit.

| diesel Performance Modifications cold Air Intake

All diesel engines require unimpeded airflow to perform at their best. Quite simply, the more air you can flow through an engine, the more oxygen will be available for burning fuel, and the more power you will make.

The stock air intake on your truck typically restricts airflow in two ways. First is the design of the intake box itself. Most trucks use an air inlet that draws in air from either the inner fender or the radiator bulkhead to meet the manufacturer's standards for induction and drive-by noise. This can dramatically limit the flow of fresh air to the engine. Second is the high-capacity paper filter element inside the box, which tends to slow the flow of air streaming into the intake even further.

Fortunately, this is an easy fix. There are any number of aftermarket companies now that offer complete air intake kits that replace the entire airbox with a high-flow system. These typically include an oiled, cotton-gauze (or synthetic) filter that, even when filthy, will flow more air than the paper element ever could. This upgrade will translate to better air/fuel ratios, greater engine efficiency, and more usable horsepower and torque. This is a simple upgrade and one that you will feel immediately. Throttle response will be sharper, and your gas mileage should go up just a bit.

| diesel Performance Modifications gauges

As you sit around daydreaming about all the great upgrades you have planned for your truck, gauges may rank low on the list. But, remember, most of the modifications you make to your diesel will cause it to produce more power and place greater demands on your vehicle's systems. Well-designed gauges will give you a good jump on any problems that could arise.

There are few things that will destroy your engine faster than excessive exhaust gas temperature (EGT). So, at the top of the gauge list should be a pyrometer. This gauge will monitor EGT levels and give you advanced warning of anything dire. This gauge comes with a thermocouple probe that can either be installed on the exhaust manifold or behind the turbine outlet on the turbocharger. It's up to you, but we recommend removing the turbo and drilling the manifold for the most accurate numbers.

Next up would be a boost gauge, which is used to monitor turbocharger performance. High-end models will allow you to target your ideal boost setting and reconfigure it according to your engine specifications.

Many gearheads disregard it, but transmission temperature should be monitored along with everything else on your truck. Once you know the standard operating temperature of your transmission, it's easy to glance at the gauge occasionally to make sure everything is running smoothly. A blown transmission is an expensive repair, and a simple little gauge could go a long way toward extending its life.

| diesel Performance Modifications gauges

As you sit around daydreaming about all the great upgrades you have planned for your truck, gauges may rank low on the list. But, remember, most of the modifications you make to your diesel will cause it to produce more power and place greater demands on your vehicle's systems. Well-designed gauges will give you a good jump on any problems that could arise.

There are few things that will destroy your engine faster than excessive exhaust gas temperature (EGT). So, at the top of the gauge list should be a pyrometer. This gauge will monitor EGT levels and give you advanced warning of anything dire. This gauge comes with a thermocouple probe that can either be installed on the exhaust manifold or behind the turbine outlet on the turbocharger. It's up to you, but we recommend removing the turbo and drilling the manifold for the most accurate numbers.

Next up would be a boost gauge, which is used to monitor turbocharger performance. High-end models will allow you to target your ideal boost setting and reconfigure it according to your engine specifications.

Many gearheads disregard it, but transmission temperature should be monitored along with everything else on your truck. Once you know the standard operating temperature of your transmission, it's easy to glance at the gauge occasionally to make sure everything is running smoothly. A blown transmission is an expensive repair, and a simple little gauge could go a long way toward extending its life.

| diesel Performance Modifications torque Converter

As you go about the process of turning your diesel truck into a high-performance machine with gut-wrenching torque and horsepower, it's easy to forget about the transmission. You don't look at it every day (it's not particularly sexy), and you wouldn't think it would make you go any faster. However, if you abuse it enough, it does have the ability to slow you down and even bring you to a grinding halt.

The stock transmission in your truck is designed for stock power output-or something close-when towing at maximum gross combined weight rating (GCWR). But, by the time you upgrade your turbo, add propane injection, stack on a couple of computer modules, and do some high-end tuning, you've left that transmission far behind-hopefully, not literally. That's why turning to an aftermarket transmission or opting to have your own rebuilt makes a lot of sense. Transmissions built for extreme duty have a number of things in common. They are usually equipped with more clutch plates to handle heavy loads and high horsepower. These extra clutches prevent slippage when the transmission shifts. Some of these transmissions also include high-performance valvebodies to provide increased line pressures and improved ATF flow through the coolers, which results in better shift quality and extended life.

Torque converters also take their fair share of abuse. With enough horsepower, torque, and load, the clutch inside the converter can start to slip, which results in friction and heat. Ultimately, the converter can deform and self-destruct. High-performance converters are typically built using a billet steel shell to better withstand heat and abuse, and they are designed with multiple clutch discs that significantly increase the converter's clutch-holding power.

| diesel Performance Modifications torque Converter

As you go about the process of turning your diesel truck into a high-performance machine with gut-wrenching torque and horsepower, it's easy to forget about the transmission. You don't look at it every day (it's not particularly sexy), and you wouldn't think it would make you go any faster. However, if you abuse it enough, it does have the ability to slow you down and even bring you to a grinding halt.

The stock transmission in your truck is designed for stock power output-or something close-when towing at maximum gross combined weight rating (GCWR). But, by the time you upgrade your turbo, add propane injection, stack on a couple of computer modules, and do some high-end tuning, you've left that transmission far behind-hopefully, not literally. That's why turning to an aftermarket transmission or opting to have your own rebuilt makes a lot of sense. Transmissions built for extreme duty have a number of things in common. They are usually equipped with more clutch plates to handle heavy loads and high horsepower. These extra clutches prevent slippage when the transmission shifts. Some of these transmissions also include high-performance valvebodies to provide increased line pressures and improved ATF flow through the coolers, which results in better shift quality and extended life.

Torque converters also take their fair share of abuse. With enough horsepower, torque, and load, the clutch inside the converter can start to slip, which results in friction and heat. Ultimately, the converter can deform and self-destruct. High-performance converters are typically built using a billet steel shell to better withstand heat and abuse, and they are designed with multiple clutch discs that significantly increase the converter's clutch-holding power.

| diesel Performance Modifications turbo

The theory behind turbochargers is simple: The more air you can force into an engine, the more power it will make. A turbocharger uses a turbine, which is driven by exhaust gases, and a compressor, which pressurizes the intake, to force-feed air to the engine and dramatically increase engine performance. The amount of air created by the turbo is generally referred to in terms of boost measured in pounds per square inch (psi).

Your factory turbo-assuming you have one-is designed to supply your diesel with typically two to three times the amount of air it would otherwise draw in. You need air to burn diesel fuel, but now that you've added a programmer, box, or performance calibration, chances are good you have more fuel than your engine can burn. The result is black smoke, high EGT, and poor fuel economy. Your engine needs more air. It's time for a turbo upgrade.

You might be tempted to think the bigger the turbo the better. And that's true to a certain point. Many companies offer larger turbos for the popular applications. Bigger turbos generally produce more total boost, but they also take longer to get there-and tend to provide less boost at lower engine speeds, where your engine spends most of time. Ball bearing turbos can increase boost and spool up quick, thanks to their low internal drag.

This dilemma of big boost versus turbo lag has caused some diesel owners to go with twin-turbo systems. With two turbochargers working in tandem, you can get the benefits of a quick spooling (small) turbo and the benefits of a (large) performance turbo. For Diesel Power enthusiasts, this is the ultimate because of the incredibly quick spool-up times and the sheer amount of boost created.

| diesel Performance Modifications turbo

The theory behind turbochargers is simple: The more air you can force into an engine, the more power it will make. A turbocharger uses a turbine, which is driven by exhaust gases, and a compressor, which pressurizes the intake, to force-feed air to the engine and dramatically increase engine performance. The amount of air created by the turbo is generally referred to in terms of boost measured in pounds per square inch (psi).

Your factory turbo-assuming you have one-is designed to supply your diesel with typically two to three times the amount of air it would otherwise draw in. You need air to burn diesel fuel, but now that you've added a programmer, box, or performance calibration, chances are good you have more fuel than your engine can burn. The result is black smoke, high EGT, and poor fuel economy. Your engine needs more air. It's time for a turbo upgrade.

You might be tempted to think the bigger the turbo the better. And that's true to a certain point. Many companies offer larger turbos for the popular applications. Bigger turbos generally produce more total boost, but they also take longer to get there-and tend to provide less boost at lower engine speeds, where your engine spends most of time. Ball bearing turbos can increase boost and spool up quick, thanks to their low internal drag.

This dilemma of big boost versus turbo lag has caused some diesel owners to go with twin-turbo systems. With two turbochargers working in tandem, you can get the benefits of a quick spooling (small) turbo and the benefits of a (large) performance turbo. For Diesel Power enthusiasts, this is the ultimate because of the incredibly quick spool-up times and the sheer amount of boost created.

| diesel Performance Modifications injectors

Now that you've added more fuel with computer tricks and improved your engine's ability to pump air, it may be time to look into a new set of injectors. With diesel engines, the role of the injectors in overall performance can be huge. The aftermarket offers performance injectors that are typically based on stock units that are reworked to flow more fuel at a given setting. The key here is to match the injector with your usage. Typically, injectors are rated for horsepower levels. The amount of diesel fuel required to support a particular power level can be calculated. And in a perfect world you want injectors that won't be overkill for your application yet aren't maxed out either. Like most things in life, injectors have a sweet spot where they work best.

Some performance enthusiasts like running an auxiliary electric lift pump as insurance to protect the injection pump, usually at the least opportune time. Some truck owners turn to aftermarket lift pumps out of sheer necessity. Duramax owners should consider an electric lift pump at anything above stock power levels because these trucks don't have lift pumps at all.

At best, the stock lift pump is designed to provide fuel delivery for a stock engine. Once you begin adding the kinds of aftermarket upgrades we've been talking about, the demand for fuel goes up, too. The stock lift pump quickly falls short. Fluctuations in performance at higher rpm and engine load will signal it's time for an upgrade.

In a turbodiesel engine system, the intercooler is designed to do one thing: Cool the air after it leaves the turbocharger and before it reaches the engine. Sometimes called charge-air cooling, this process has tremendous impact on engine performance. As pressurized air passes through the intercooler from the turbocharger, the temperature of the air drops and it becomes more dense. Cooler, denser air allows greater amounts of fuel to be burned, which means greater horsepower. Cooler, denser air also means lower exhaust gas temperature (EGT), which allows the engine to perform even more efficiently.

Basically, an intercooler is a heat exchanger. And as with all heat exchangers, the greater the surface area, the more efficiently it cools. Stock intercoolers are fine for stock applications. But, as you expand the performance attributes of your truck, the stock unit may not keep up. Most aftermarket intercoolers are one-piece, aluminum, fin-type models with inlets and outlets that are much larger than stock to provide greater flow of air. Using ambient air flowing through the grille and radiator, a high-performance intercooler will dramatically lower the temperature of the boost intake air and contribute to optimal engine performance. So whether you are converting to a turbo setup or swapping in a bigger turbo, don't shortchange on your intercooler. It's one of the best improvements you'll make.

| diesel Performance Modifications injectors

Now that you've added more fuel with computer tricks and improved your engine's ability to pump air, it may be time to look into a new set of injectors. With diesel engines, the role of the injectors in overall performance can be huge. The aftermarket offers performance injectors that are typically based on stock units that are reworked to flow more fuel at a given setting. The key here is to match the injector with your usage. Typically, injectors are rated for horsepower levels. The amount of diesel fuel required to support a particular power level can be calculated. And in a perfect world you want injectors that won't be overkill for your application yet aren't maxed out either. Like most things in life, injectors have a sweet spot where they work best.

Some performance enthusiasts like running an auxiliary electric lift pump as insurance to protect the injection pump, usually at the least opportune time. Some truck owners turn to aftermarket lift pumps out of sheer necessity. Duramax owners should consider an electric lift pump at anything above stock power levels because these trucks don't have lift pumps at all.

At best, the stock lift pump is designed to provide fuel delivery for a stock engine. Once you begin adding the kinds of aftermarket upgrades we've been talking about, the demand for fuel goes up, too. The stock lift pump quickly falls short. Fluctuations in performance at higher rpm and engine load will signal it's time for an upgrade.

In a turbodiesel engine system, the intercooler is designed to do one thing: Cool the air after it leaves the turbocharger and before it reaches the engine. Sometimes called charge-air cooling, this process has tremendous impact on engine performance. As pressurized air passes through the intercooler from the turbocharger, the temperature of the air drops and it becomes more dense. Cooler, denser air allows greater amounts of fuel to be burned, which means greater horsepower. Cooler, denser air also means lower exhaust gas temperature (EGT), which allows the engine to perform even more efficiently.

Basically, an intercooler is a heat exchanger. And as with all heat exchangers, the greater the surface area, the more efficiently it cools. Stock intercoolers are fine for stock applications. But, as you expand the performance attributes of your truck, the stock unit may not keep up. Most aftermarket intercoolers are one-piece, aluminum, fin-type models with inlets and outlets that are much larger than stock to provide greater flow of air. Using ambient air flowing through the grille and radiator, a high-performance intercooler will dramatically lower the temperature of the boost intake air and contribute to optimal engine performance. So whether you are converting to a turbo setup or swapping in a bigger turbo, don't shortchange on your intercooler. It's one of the best improvements you'll make.

| diesel Performance Modifications nitrous

Another option for pulling more power from turbodiesels is nitrous oxide injection. When nitrous is injected into the intake air, the heat of compression breaks the molecules down into nitrogen and oxygen. It is this extra oxygen burst that allows the engine to burn greater amounts of diesel fuel. The more air you can pack into the combustion chamber, the more fuel you can burn, and the more power you can produce. Nitrous is literally like a turbocharger in a bottle. Naturally, though, all systems have their limits, and then fun ends when the bottle runs out.

For heavy-duty tow rigs and street racers, this might well be the final power upgrade. Often referred to as chemical intercooling, water/methanol injection provides big gains in power with cooler combustion temperatures. Running a 50/50 water/methanol mix, it's typical to see gains of 70-plus horsepower, 100-plus lb-ft of torque, and 3 to 5 psi of boost, all with a decrease of 200-plus degrees in exhaust gas temperature.

The science behind this technology has been around for decades, and the mix has long been popular with drag racers. Basically, a high-pressure pump injects the water/methanol mixture into the intake plenum. Small nozzles spray in the juice as the turbo boost level comes up. Usually, an electronic controller meters out the amount of water/methanol so that it remains proportional to boost levels. The burst of speed you get as you drop the hammer is considerable. And it's perfect for lowering EGT when pulling heavy loads up steep inclines or simply enjoying the wow-factor on the quarter-mile.

| diesel Performance Modifications nitrous

Another option for pulling more power from turbodiesels is nitrous oxide injection. When nitrous is injected into the intake air, the heat of compression breaks the molecules down into nitrogen and oxygen. It is this extra oxygen burst that allows the engine to burn greater amounts of diesel fuel. The more air you can pack into the combustion chamber, the more fuel you can burn, and the more power you can produce. Nitrous is literally like a turbocharger in a bottle. Naturally, though, all systems have their limits, and then fun ends when the bottle runs out.

For heavy-duty tow rigs and street racers, this might well be the final power upgrade. Often referred to as chemical intercooling, water/methanol injection provides big gains in power with cooler combustion temperatures. Running a 50/50 water/methanol mix, it's typical to see gains of 70-plus horsepower, 100-plus lb-ft of torque, and 3 to 5 psi of boost, all with a decrease of 200-plus degrees in exhaust gas temperature.

The science behind this technology has been around for decades, and the mix has long been popular with drag racers. Basically, a high-pressure pump injects the water/methanol mixture into the intake plenum. Small nozzles spray in the juice as the turbo boost level comes up. Usually, an electronic controller meters out the amount of water/methanol so that it remains proportional to boost levels. The burst of speed you get as you drop the hammer is considerable. And it's perfect for lowering EGT when pulling heavy loads up steep inclines or simply enjoying the wow-factor on the quarter-mile.