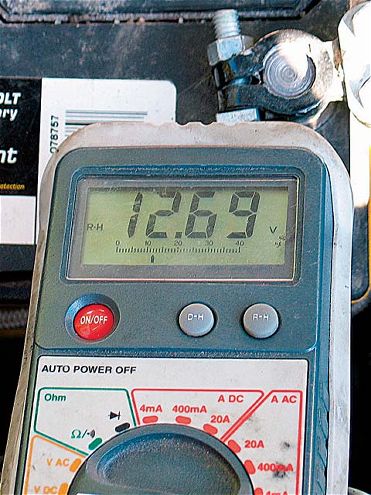

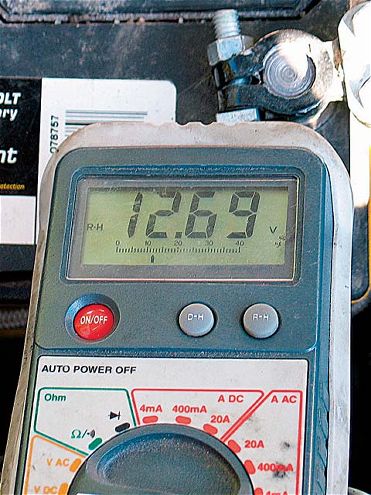

| 1. Using the basics we've described, let's try to figure out why our compressor isn't turning on. Start by metering the positive lead coming from the starter solenoid to the battery. It's getting voltage, so we'll move on.

This article provides background information that will help you troubleshoot most basic electrical problems. Included are some basic hints when trying to track down an electrical failure, whether it's your stereo, your air system, or your cigarette lighter- powered blender. Diagnosing electrical-system problems can seem very overwhelming at first, but if you break it down into the system's components, it becomes much easier. Some people just replace things until they eventually fix the faulty part. While there are times when this is the best way (to substitute a known good part), it can be costly, not to mention frustrating. Instead, use your money to purchase a quality volt-ohm meter that can read voltage, resistance (ohms), and continuity.

The most helpful tool you can have is a high-impedance volt-ohm meter (low-impedance Voltmeters will give misleading information and can damage sensitive electronics). An accurate wiring diagram will quicken the diagnosis process tremendously but is not always available, so we also included a wiring diagram of the issue we'll be troubleshooting in this tech piece. Whenever you're making electrical repairs or doing work on your truck, always disconnect the battery. Batteries can and do explode, so avoid creating sparks near the battery by turning all accessories and the key off before undoing the cables. The negative side should be the first thing undone and the last side reconnected.

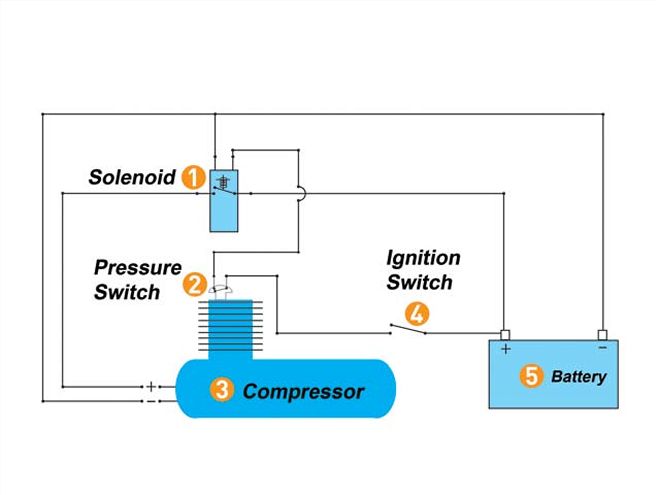

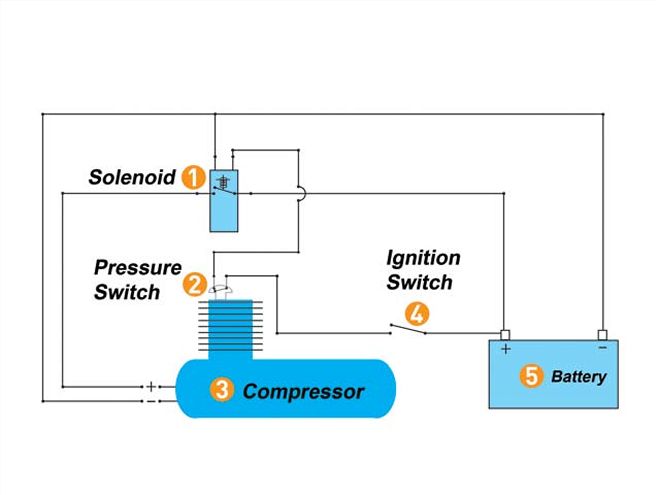

| Diagram by Gary Blount

Consider the electrical system on your vehicle as a collection of many smaller sub-systems that are capable of working independently of each other. Electrical circuits can be broken down into six simple components: power source, protection, control, load, ground, and wiring. The battery is considered the power source, protection is the fuse or circuit breaker, control is the switch, load is the component doing the work (compressor, headlights, coil, and so on), and a good ground completes the circuit. The wiring is what connects everything together. Remove any one component and the system will not work. Electrical diagnosis is a systematic method of identifying and correcting the problem component. The main problems you'll run into are open circuits, shorted circuits, excessive resistance, and faulty parts.

| 2. Next, check the pressure switch. First, check to see if the switch is getting voltage by grounding the negative lead on the meter and probing one side.

In this tech piece, we'll use some basic steps addressed to try to track down the possible reasons why our air compressor will not turn on. Always begin with the basics in any electrical system by checking for a fully charged battery; clean battery terminals; positive and negative cables with proper routing and clean, tight connections; and fuses that might be blown. Most electrical diagnoses are done with the battery hooked up and the system operating (you can't check the turn signals without first turning on the ignition switch and placing the turn signal lever either in the left or right position).

| 3. It has voltage, so check continuity between the leads to make sure the pressure switch is working. The pressure switch is working, so we'll continue to the next part.

Open CircuitsUse your meter to make a quick check for continuity. Hook one lead of your meter to one side of the circuit and the other lead to the other side. If your meter has a sound function, it will beep to signify continuity. However, this will not be the case in an open-circuit situation. The current is not getting to the end source because of a break somewhere in the circuit. Turn the faulty circuit (your compressor) on and use your meter to check for voltage at various points. If you get a voltage reading of 12 or more, your circuit is probably good to that point. Check the ground or negative side of your load to make sure it's good. Most problems occur in the ground side of a circuit. The quickest test for an open ground is to run a known good ground wire (jumper wire). If your meter did not read voltage at the positive side of the load, then back up to the switch controlling the circuit (pressure switch). Your meter should read voltage when you probe both sides of the switch. If it doesn't read voltage yet, back up to the fuse block. If the entire circuit is getting the necessary voltage, then the problem is probably a faulty part.

| 4. Now check the voltage on the starter solenoid. This acts as a relay for the compressors. Never run your compressors directly to the battery because of their amperage draw.

Excessive ResistanceA volt-ohm meter measures voltage potential and can be used to measure resistance in an operating circuit. Learning to do a voltage-drop test will help you solve the majority of your electrical problems. Some tests are easier if you have another person help. To test for a voltage drop, don't disconnect or remove any wiring or components in the circuit you're testing. This test is used to isolate excessive resistance in the wiring leading to and from your load. To check the hot side of your circuit, hook the positive lead of your voltmeter to the positive side of your battery. Hook the negative lead of your voltmeter to the hot side of your load. Operate the circuit and read the voltage displayed on your voltmeter. For high-current wires (battery cables), you should read less than 0.2 volts. Allow 0.1 volts maximum for every switch or relay contact in the circuit located between your test leads. All other wiring should read less than 0.1 volts (some fuel-injected circuits are less). To check the negative side of your circuit, hook the positive lead of your voltmeter to the negative side of your load and the negative lead of your voltmeter to the negative side of the battery or a known good ground. Operate the circuit and read the voltage on your meter. Any voltmeter readings above 0.2 volts while attempting to operate the circuit being tested indicates excessive resistance. Use your voltmeter to locate excessive resistance by isolating sections of the circuit between your test leads. If you isolate a broken wire between your test leads and attempt to operate your circuit, your Voltmeter will read battery voltage.

| 5. The solenoid is getting voltage on both the compressor side and the positive battery side.

Short CircuitsShort circuits show up as blown fuses, melted fusible links, and burned wiring. Never replace burned fuses with a fuse of a higher rating. Short circuits are easy to identify, but not always easy to locate. Something may be grounding out because it's been burned through or melted to another wire. Using a test light between a blown fuse can help locate the short. When the short circuit is present, the light will glow at full intensity. If the short is intermittent, the circuit should work normally and the light will not glow at full intensity until the short occurs. You can locate most intermittent shorts by wiggling the wiring in the suspected circuits. This is where a wiring diagram comes in handy, as some fuses protect more than one circuit. While the test lamp glows at full intensity, start disconnecting, one at a time, the different loads in that circuit. When you disconnect the offending load or wiring connector from a wire harness and the test light goes out, your short circuit is down the line from that point.

| 6. Next, we jumped the solenoid to see if the compressors were bad. The compressors turned on (ah, the sound of air). Since the solenoid was getting voltage and worked when jumped, the solenoid was our faulty part and the reason why the compressors wouldn't turn on.

Faulty PartsBy using the methods above with the appropriate repair manual and wiring diagrams, you can check all the wiring in your vehicle. These tests will help you determine whether your load or wiring is faulty. If you suspect your load device as the cause, the repair manual should be able to provide you with specific vehicle-testing methods. Some manuals will not give specific testing instructions; they might tell you to substitute a known good part. If you conduct your diagnosis properly, you can feel safe buying that expensive, nonreturnable electrical part.

| 7. After making a run to AutoZone to pickup a Ford starter solenoid and installing it, our compressors were purring like new.

Poor GroundsPoor grounds cause many different problems. Dim lights, slow or no cranking, and poor battery charging are classic indications of poor grounds. Use your voltmeter to do a voltage-drop test to check for poor grounds. Hook the negative lead of your voltmeter to the negative side of the battery and the positive lead to a good ground location on your engine block and note the voltage while cranking the engine. Check the body ground by moving your positive test lead to the body and turn on all lights and accessories, noting the voltage reading. Anything above 0.2 volts indicates excessive resistance in the ground connection or ground cable.

| 1. Using the basics we've described, let's try to figure out why our compressor isn't turning on. Start by metering the positive lead coming from the starter solenoid to the battery. It's getting voltage, so we'll move on.

This article provides background information that will help you troubleshoot most basic electrical problems. Included are some basic hints when trying to track down an electrical failure, whether it's your stereo, your air system, or your cigarette lighter- powered blender. Diagnosing electrical-system problems can seem very overwhelming at first, but if you break it down into the system's components, it becomes much easier. Some people just replace things until they eventually fix the faulty part. While there are times when this is the best way (to substitute a known good part), it can be costly, not to mention frustrating. Instead, use your money to purchase a quality volt-ohm meter that can read voltage, resistance (ohms), and continuity.

The most helpful tool you can have is a high-impedance volt-ohm meter (low-impedance Voltmeters will give misleading information and can damage sensitive electronics). An accurate wiring diagram will quicken the diagnosis process tremendously but is not always available, so we also included a wiring diagram of the issue we'll be troubleshooting in this tech piece. Whenever you're making electrical repairs or doing work on your truck, always disconnect the battery. Batteries can and do explode, so avoid creating sparks near the battery by turning all accessories and the key off before undoing the cables. The negative side should be the first thing undone and the last side reconnected.

| 1. Using the basics we've described, let's try to figure out why our compressor isn't turning on. Start by metering the positive lead coming from the starter solenoid to the battery. It's getting voltage, so we'll move on.

This article provides background information that will help you troubleshoot most basic electrical problems. Included are some basic hints when trying to track down an electrical failure, whether it's your stereo, your air system, or your cigarette lighter- powered blender. Diagnosing electrical-system problems can seem very overwhelming at first, but if you break it down into the system's components, it becomes much easier. Some people just replace things until they eventually fix the faulty part. While there are times when this is the best way (to substitute a known good part), it can be costly, not to mention frustrating. Instead, use your money to purchase a quality volt-ohm meter that can read voltage, resistance (ohms), and continuity.

The most helpful tool you can have is a high-impedance volt-ohm meter (low-impedance Voltmeters will give misleading information and can damage sensitive electronics). An accurate wiring diagram will quicken the diagnosis process tremendously but is not always available, so we also included a wiring diagram of the issue we'll be troubleshooting in this tech piece. Whenever you're making electrical repairs or doing work on your truck, always disconnect the battery. Batteries can and do explode, so avoid creating sparks near the battery by turning all accessories and the key off before undoing the cables. The negative side should be the first thing undone and the last side reconnected.

| Diagram by Gary Blount

Consider the electrical system on your vehicle as a collection of many smaller sub-systems that are capable of working independently of each other. Electrical circuits can be broken down into six simple components: power source, protection, control, load, ground, and wiring. The battery is considered the power source, protection is the fuse or circuit breaker, control is the switch, load is the component doing the work (compressor, headlights, coil, and so on), and a good ground completes the circuit. The wiring is what connects everything together. Remove any one component and the system will not work. Electrical diagnosis is a systematic method of identifying and correcting the problem component. The main problems you'll run into are open circuits, shorted circuits, excessive resistance, and faulty parts.

| Diagram by Gary Blount

Consider the electrical system on your vehicle as a collection of many smaller sub-systems that are capable of working independently of each other. Electrical circuits can be broken down into six simple components: power source, protection, control, load, ground, and wiring. The battery is considered the power source, protection is the fuse or circuit breaker, control is the switch, load is the component doing the work (compressor, headlights, coil, and so on), and a good ground completes the circuit. The wiring is what connects everything together. Remove any one component and the system will not work. Electrical diagnosis is a systematic method of identifying and correcting the problem component. The main problems you'll run into are open circuits, shorted circuits, excessive resistance, and faulty parts.

| 2. Next, check the pressure switch. First, check to see if the switch is getting voltage by grounding the negative lead on the meter and probing one side.

In this tech piece, we'll use some basic steps addressed to try to track down the possible reasons why our air compressor will not turn on. Always begin with the basics in any electrical system by checking for a fully charged battery; clean battery terminals; positive and negative cables with proper routing and clean, tight connections; and fuses that might be blown. Most electrical diagnoses are done with the battery hooked up and the system operating (you can't check the turn signals without first turning on the ignition switch and placing the turn signal lever either in the left or right position).

| 2. Next, check the pressure switch. First, check to see if the switch is getting voltage by grounding the negative lead on the meter and probing one side.

In this tech piece, we'll use some basic steps addressed to try to track down the possible reasons why our air compressor will not turn on. Always begin with the basics in any electrical system by checking for a fully charged battery; clean battery terminals; positive and negative cables with proper routing and clean, tight connections; and fuses that might be blown. Most electrical diagnoses are done with the battery hooked up and the system operating (you can't check the turn signals without first turning on the ignition switch and placing the turn signal lever either in the left or right position).  | 3. It has voltage, so check continuity between the leads to make sure the pressure switch is working. The pressure switch is working, so we'll continue to the next part.

Open Circuits

| 3. It has voltage, so check continuity between the leads to make sure the pressure switch is working. The pressure switch is working, so we'll continue to the next part.

Open Circuits | 4. Now check the voltage on the starter solenoid. This acts as a relay for the compressors. Never run your compressors directly to the battery because of their amperage draw.

Excessive Resistance

| 4. Now check the voltage on the starter solenoid. This acts as a relay for the compressors. Never run your compressors directly to the battery because of their amperage draw.

Excessive Resistance | 5. The solenoid is getting voltage on both the compressor side and the positive battery side.

Short Circuits

| 5. The solenoid is getting voltage on both the compressor side and the positive battery side.

Short Circuits | 6. Next, we jumped the solenoid to see if the compressors were bad. The compressors turned on (ah, the sound of air). Since the solenoid was getting voltage and worked when jumped, the solenoid was our faulty part and the reason why the compressors wouldn't turn on.

Faulty Parts

| 6. Next, we jumped the solenoid to see if the compressors were bad. The compressors turned on (ah, the sound of air). Since the solenoid was getting voltage and worked when jumped, the solenoid was our faulty part and the reason why the compressors wouldn't turn on.

Faulty Parts | 7. After making a run to AutoZone to pickup a Ford starter solenoid and installing it, our compressors were purring like new.

Poor Grounds

| 7. After making a run to AutoZone to pickup a Ford starter solenoid and installing it, our compressors were purring like new.

Poor Grounds