Steam engines and diesel engines have a lot in common. First off, they share the same blood, or to put it differently, they both use heat to make mechanical power. Secondly, these combustion brothers suffer from a negative and ill-informed public image. Close your eyes and say the words steam power. More than likely, you'll picture an old locomotive or a huge stationary engine powering a convoluted belt system like that out of a Dickens novel. Truth is, if we put our emotions aside and look at steam (or diesel) engines rationally, a totally different picture emerges.

| cyclone Mark V Steam Engine side Angle

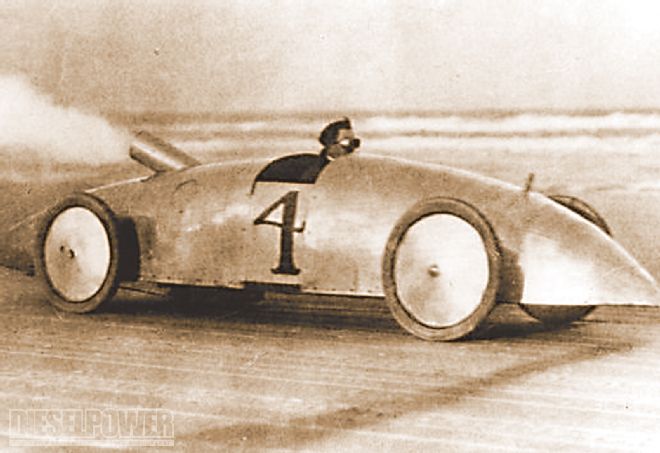

200-MPH Land Speed Record Breaker

The U.S. Land Steam Record Team led by Chuk Williams picked the Cyclone Mark V engine to accomplish its Bonneville speed goal of 200 mph for a number of reasons, including: 860 lb-ft of starting torque (at 1 rpm), compact engine design with few moving parts for better aerodynamics, simplicity, and a total weight of only 336 pounds. This project is endorsed by the Steam Automobile Club of America and has a team of former engineers from NASA, Lockheed Martin, and MIT. Together, with inventor of the Cyclone, Harry Schoell, the group plans to smash the old record (August 2009) of 148 mph set by Team Inspiration of Great Britain. Amazingly, back in 1906, a Stanley Steamer went 127 mph at Daytona Beach, so clearly steam produced by external combustion has an unrealized potential.

Mechanical Energy Process

1. Fuel is atomized and injected into the circular combustion chamber (shown as lifted off the engine block for better viewing), and then a spark ignites the fuel and air mixture into a flame that spins around the coils. Thermocouples (not pictured) regulate the timing of combustion to keep the heat in the combustion chamber at a constant controlled temperature. Emissions such as carbon monoxide and NOx form at temperatures and pressures above a certain point. Therefore, the Cyclone burns fuel below 2,300 degrees and at atmospheric pressure, so pretty much only carbon dioxide and water vapor is left in the exiting 320-degree exhaust.

| cyclone Mark V Steam Engine mechanical Energy

2. According to Cyclone, water contained in the coils becomes superheated steam (1,200 degrees) in as little as 5 seconds from start-up, which is (A) piped to the cylinders (B) where it enters through a valve system (not pictured). Note that valve-timing mechanisms regulate how much steam enters the cylinders—the longer the cutoff, the greater the torque and acceleration.

3. Cyclone goes on to explain that steam enters the six radial configured cylinders under pressures greater than 3,200 psi to push the pistons down in sequence and produces 100 hp at 3,600 rpm. Note: No motor oil is used, as water is both the working fluid and engine lubricant. Also, because of the valve design, the engine starts without the need of a starter motor.

4. The pistons transfer torque to a spider bearing (not pictured) that turns the crankshaft at 34 percent thermal efficiency. Cyclone told us that because the greatest amount of torque occurs at the first rotation, the shaft is directly connected to the drivetrain without the need for a transmission or clutch.

5. In most Cyclone engines, steam exits the cylinders and goes through the exhaust ports and (A) enters the condensing unit where it turns back into water and (B) collects in a sealed pan at the bottom of the condenser. This means it's a closed-loop system and the water does not need to be replaced or topped off. Although, in the land speed application, the vehicle's engine is slightly modified by removing the condenser and making the system open like the locomotives of old, which allows massive amounts of fuel to be run through the engine, producing more power but less efficiency than normal.