| BEFORE

In the custom scene, there's one thing that most people strive for: the ability to stand out at a show. That uniqueness is without a doubt worth its weight in trophies and recognition. While front-end conversions and taillight swaps may take care of the exterior and fiberglass may take care of the interior of your truck, the options for engine dress-up have been relatively limited -- that is, until now.

Optiflo Inc. is introducing an idea that may single-handedly revolutionize the way engine compartments will look at future shows. The concept is to remove the plain, boring rubber hoses from your engine and replace them with glass extensions that not only conform to the original hoses, but will also allow never-before-seen visual elements -- such as radiator fluid flowing in and out of the block and through heater hoses, or vacuum wisps moving over the block -- to be visible.

| AFTER

There are some immediate concerns that come to mind at the mention of sticking any type of glass under the hood on a turbulent, hot engine. First and foremost, what is going to keep it from shattering? According to Todd Townsend, creator of Optiflo Inc., the glass tubes the company uses have a wall thickness as large as 4 millimeters and are made of the same material as Pyrex ovenware. To prove to us how strong the glass is, he put it head to head against a 2x4-inch wood plank, the shop wall, and a metal filing cabinet -- all of which lost to the glass. He even placed the tube on the ground and stood on it to show off its structural rigidity.

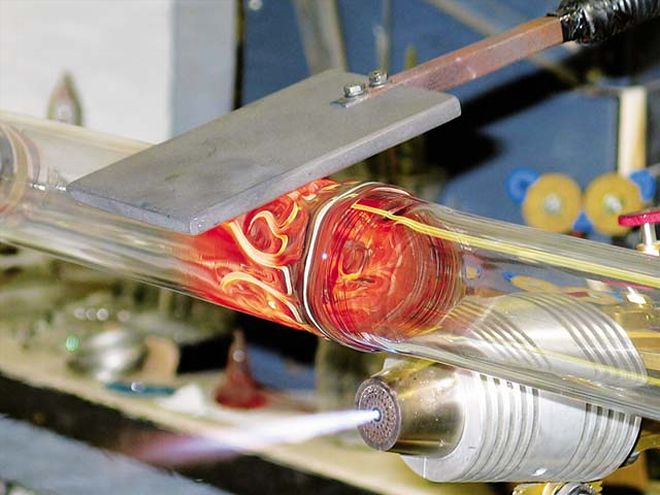

The second question we had was how it would handle the heat from the fluid within the radiator and heater hoses as well as the overall temperature from within the engine compartment. Todd explained that the glass is heated to extreme temperatures during the manipulation stage and is then set into a kiln for about an hour to cool off at more than 1,000 degrees. Considering that the temperature of your engine would only sit around the 210-degree mark on a hot day, heat is not an issue.

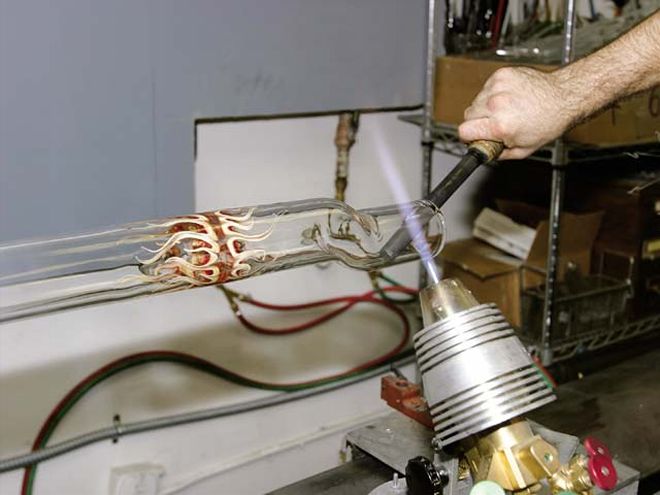

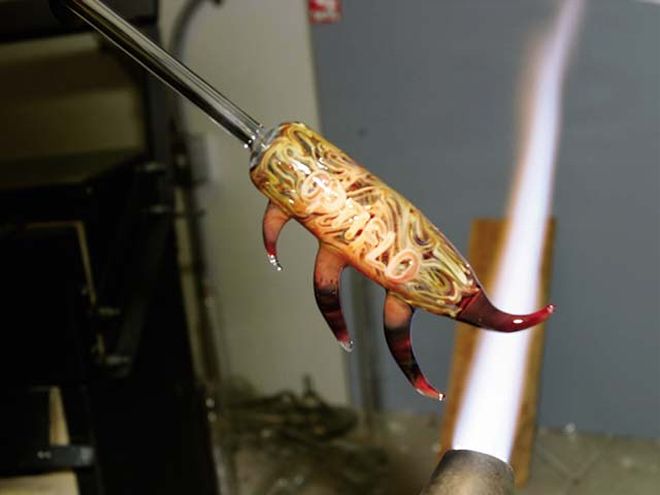

Follow along as we remove the intake, vacuum hoses, radiator hoses, and heater hoses on our '93 Toyota, and then let the crew at Optiflo work its magic. Since the glass can be manipulated into any form and decorated with any design, the possibilities for this application are endless.

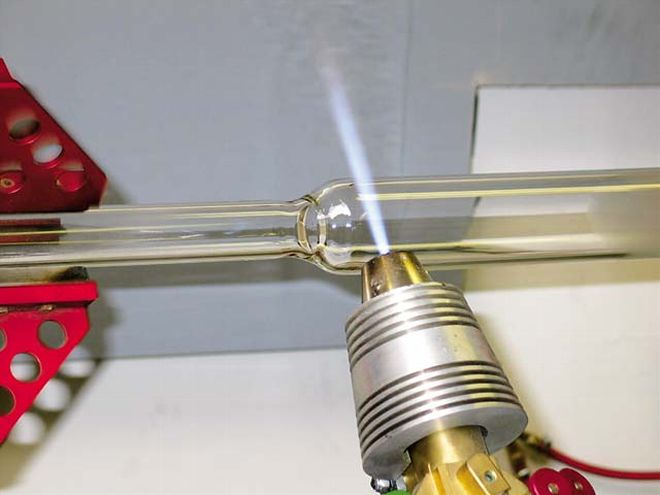

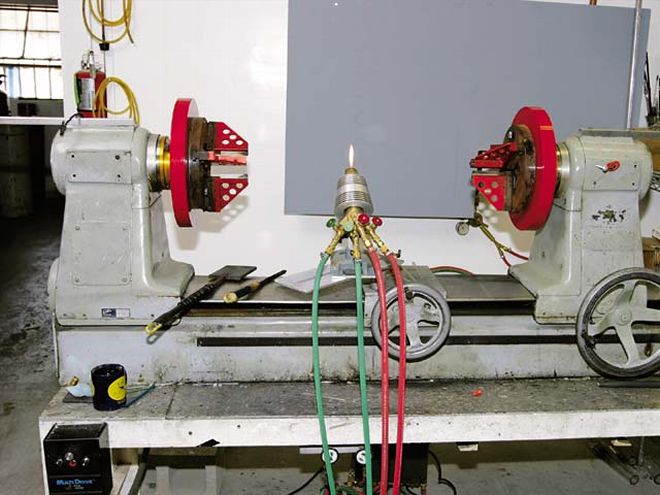

Tools of the Trade1. Graphite tools are used to bend and smooth the glass while in the fire. The graphite does not transfer heat like other metals would, so they can come into contact with the glass for longer periods of time. 2. The artist lathe and torch is where all the magic happens. The lathe keeps the glass turning at an even pace, and the torch can be adjusted to apply more or less heat. 3. The term blowing glass comes from the medical tubing that is inserted into the glass. The artist can blow air into the tube if the glass begins to collapse or suck air out of the tube if it begins to expand.

Finishing the 'FloHere you can see what a visual impact the glass adds. The radiator fluid can be seen flowing through the radiator and heater hoses. Considering that radiator fluid comes in just about any color now, the color combinations to match your truck are endless.

| BEFORE

In the custom scene, there's one thing that most people strive for: the ability to stand out at a show. That uniqueness is without a doubt worth its weight in trophies and recognition. While front-end conversions and taillight swaps may take care of the exterior and fiberglass may take care of the interior of your truck, the options for engine dress-up have been relatively limited -- that is, until now.

Optiflo Inc. is introducing an idea that may single-handedly revolutionize the way engine compartments will look at future shows. The concept is to remove the plain, boring rubber hoses from your engine and replace them with glass extensions that not only conform to the original hoses, but will also allow never-before-seen visual elements -- such as radiator fluid flowing in and out of the block and through heater hoses, or vacuum wisps moving over the block -- to be visible.

| BEFORE

In the custom scene, there's one thing that most people strive for: the ability to stand out at a show. That uniqueness is without a doubt worth its weight in trophies and recognition. While front-end conversions and taillight swaps may take care of the exterior and fiberglass may take care of the interior of your truck, the options for engine dress-up have been relatively limited -- that is, until now.

Optiflo Inc. is introducing an idea that may single-handedly revolutionize the way engine compartments will look at future shows. The concept is to remove the plain, boring rubber hoses from your engine and replace them with glass extensions that not only conform to the original hoses, but will also allow never-before-seen visual elements -- such as radiator fluid flowing in and out of the block and through heater hoses, or vacuum wisps moving over the block -- to be visible.

| AFTER

There are some immediate concerns that come to mind at the mention of sticking any type of glass under the hood on a turbulent, hot engine. First and foremost, what is going to keep it from shattering? According to Todd Townsend, creator of Optiflo Inc., the glass tubes the company uses have a wall thickness as large as 4 millimeters and are made of the same material as Pyrex ovenware. To prove to us how strong the glass is, he put it head to head against a 2x4-inch wood plank, the shop wall, and a metal filing cabinet -- all of which lost to the glass. He even placed the tube on the ground and stood on it to show off its structural rigidity.

The second question we had was how it would handle the heat from the fluid within the radiator and heater hoses as well as the overall temperature from within the engine compartment. Todd explained that the glass is heated to extreme temperatures during the manipulation stage and is then set into a kiln for about an hour to cool off at more than 1,000 degrees. Considering that the temperature of your engine would only sit around the 210-degree mark on a hot day, heat is not an issue.

Follow along as we remove the intake, vacuum hoses, radiator hoses, and heater hoses on our '93 Toyota, and then let the crew at Optiflo work its magic. Since the glass can be manipulated into any form and decorated with any design, the possibilities for this application are endless.

| AFTER

There are some immediate concerns that come to mind at the mention of sticking any type of glass under the hood on a turbulent, hot engine. First and foremost, what is going to keep it from shattering? According to Todd Townsend, creator of Optiflo Inc., the glass tubes the company uses have a wall thickness as large as 4 millimeters and are made of the same material as Pyrex ovenware. To prove to us how strong the glass is, he put it head to head against a 2x4-inch wood plank, the shop wall, and a metal filing cabinet -- all of which lost to the glass. He even placed the tube on the ground and stood on it to show off its structural rigidity.

The second question we had was how it would handle the heat from the fluid within the radiator and heater hoses as well as the overall temperature from within the engine compartment. Todd explained that the glass is heated to extreme temperatures during the manipulation stage and is then set into a kiln for about an hour to cool off at more than 1,000 degrees. Considering that the temperature of your engine would only sit around the 210-degree mark on a hot day, heat is not an issue.

Follow along as we remove the intake, vacuum hoses, radiator hoses, and heater hoses on our '93 Toyota, and then let the crew at Optiflo work its magic. Since the glass can be manipulated into any form and decorated with any design, the possibilities for this application are endless.