Ken Brubaker

Senior Editor, Four Wheeler

Ken Brubaker

Senior Editor, Four Wheeler

In 1999 Burnsville Off Road owner Dan McKeag competed in Top Truck Challenge with a bright red Wrangler TJ powered by an 8.0L Viper V-10 engine. It was 488 cubic inches of g-force goodness that was so wrong it was right. Even now, 10 years later, we still get an adrenalin surge when we think of the incredible ride we took in that rig on the winding roads in the Hollister Hills.

Fast forward to 2009. McKeag is still stuffing big engines into little Wranglers. Nowadays his shop in Burnsville, Minnesota, specializes in fitting the versatile Hemi V-8 into Wrangler JKs. Here's a riddle: What does the United States, China, Australia, Canada, Germany, Oman, Saudi Arabia, Indonesia, Mexico, Chile, Brazil, England, Italy, Russia, France and the United Arab Emirates have in common? Answer: They all have customers that have taken delivery of Hemi-converted Wranglers from Burnsville Off Road. As a matter of fact, at the time this story was written the team at Burnsville had built 158 Hemi JKs and that number increases by the week.

We recently had the opportunity to spend a day at Burnsville Off Road to see how the process of converting from V-6 to Hemi works. Burnsville offers a variety of Hemi conversions featuring a choice of 5.7-, 6.1-, 6.4-, 7.0- and 7.2-liter Hemi engines with either an automatic or manual transmission. Huh? Did we say manual? Yep, it's a beefy six-speed and the installation is a Burnsville exclusive. As you can imagine, the Hemi doesn't just saunter over to the JK, open the hood, and jump right in. Installation is a time-consuming process and most folks don't have the time or patience for a swap like this. McKeag says that 90 percent of his customers choose to have Burnsville complete the install.

To facilitate illustrating how they complete the conversion, the team at Burnsville developed a few "stations" for us to visit so we could see the highlights of a typical conversion in just a few hours. Here's how it works.

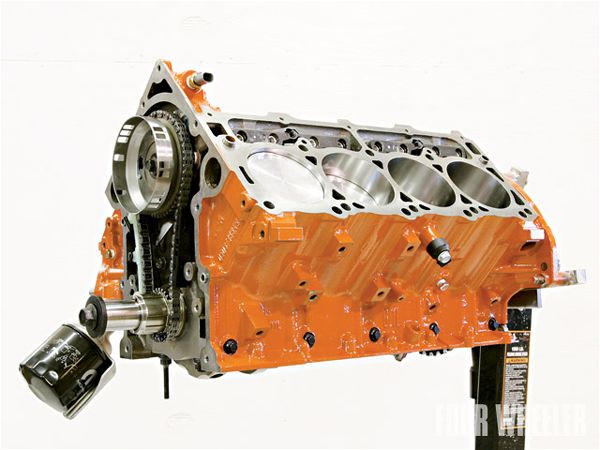

On the day of our visit the team at Burnsville was prepping this 7.0L Hemi for installation into a customers rig. It's a NASCAR-grade SRT 6.1L block that has been bored and stroked by an outside vendor that Burnsville uses regularly. Its standard features include a Callies Performance Products crankshaft, JE pistons, Eagle connecting rods, and ARP hardware. If even more power is desired, options include stuff like CNC ported and matched heads, upgraded camshafts, headers, nitrous systems, and ported and matched intakes.

We moved to another station where a 7.0L was already married to a 545RFE automatic transmission and the assembly was ready to set in the engine bay. Burnsville uses the 545RFE for those who wish to have an automatic transmission, but they'll soon offer the Mercedes-designed WA580 automatic transmission as well. The Burnsville-exclusive six-speed manual transmission we mentioned earlier fits as the result of a significant amount of R&D. It has undergone a variety of parts changes to enable it to mate and work with the Hemi, but all of the parts are available over-the-counter for ease of ownership. One of the biggest challenges in getting the six-speed to work was on the electronic side of things. We'll get to that a little later on.

PhotosView Slideshow

Here's the reality of working on modern engines. Fitting the Hemi and transmission is only half the job. Without the proper programming the engine and transmission are just worthless underhood ornaments. McKeag reports that he spent well over $150,000 and a significant amount of time on programming the engine computer. The JK has an electronic infrastructure that is far beyond the previous-generation TJ, and it all has to be deciphered and modified so the new Hemi/transmission can operate correctly. McKeag says, "The install is transparent as far as the original vehicle equipment is concerned. Absolutely everything that worked with the 3.8L engine works with the Hemi." He's referring to things like the Electronic Roll Mitigation (ERM), Electronic Stability Program (ESP), and Hill Start Assist, as well as all the vehicle's other on-board electronics. "Any dealer can troubleshoot and fix anything on the vehicle using the StarSCAN," he notes. The StarSCAN is an electronic service tool produced by Chrysler that works with the new CAN communication protocol.

So What's It Like To Drive One?

The adrenalin hit us as soon as we started the engine. The rumble from the exhaust was deep and resonant and it hinted at what was to come. As we let the clutch out the power rolled on smooth and we pointed the rig toward the open road where we could mash the throttle. With boot-to-mat, the pull of the 7.0L was pin-you-to-your-seat incredible. The six-speed shifter had a short throw with a very solid feel, and it reminded us of some high-performance sports cars we've driven. But here's the thing: In just normal commuting the engine and trans is ultra civilized. We wouldn't hesitate to hand the keys to our wife. And with the stability control and roll mitigation systems working as intended, we wouldn't hesitate to buckle the kids in too.

So What Does It Cost?

We know what you're thinking. You're thinking that this conversion probably isn't cheap. You would be correct, but hey, you wanna play...well, you know the rest. Full turnkey conversions on a JK you provide have a base price ranging from between $20,500 for a 5.7L Hemi with an automatic transmission to $43,500 for the top-of-the-line 7.2L Hemi with the six-speed manual transmission. The 7.0L conversion with automatic transmission that we installed has a price tag of $35,500. Pricing on all engine/trans combinations is available on the Burnsville website. If Burnsville completes the install with a 5.7-, 6.1- or 6.3-liter engine, you get a 3-year/30,000-mile warranty. The 7.0- and 7.2-liter engines get a 1-year/12,000-mile warranty. All transmissions have a 3-year warranty. These warranties are impressive and they show that the Burnsville team has confidence in their conversions. For do-it-yourselfer's there is a basic install kit available for $3,500.

Let's Talk Power

The factory 3.8L V-6 used in the Wrangler produces 202 hp and 237 lb-ft of torque. The base 5.7L offered by Burnsville makes 340 hp and 350 lb-ft of torque, which is a pretty dramatic improvement. But the improvement in horsepower and torque between the available Hemi displacements is even more dramatic. For instance, the 7.0L we installed makes a whopping 600 hp and 610 lb-ft of torque, while the 7.2L ups the ante even more with a stunning 710 hp and 715 lb-ft of torque.