If any engine can give a grizzled Jeeper the warm fuzzies, it's the '87-'06 Jeep 4.0L inline six. Designed by AMC and refined by Chrysler, its basic architecture was based on the '64-and-up AMC 199-, 232-, and 258ci OHV sixes. The fuel-injected 4.0L ruled supreme in Jeeps until forceably dethroned in 2006. We would like to say, "The King is dead, long live the King," but, thus far, nothing has emerged in diehard Jeepers' eyes worthy of wearing the crown. Before the late King's body cools too much, let's walk through tweaking this legendary engine from the inside out.

The old saying goes, "There's no replacement for displacement." Darn few single mods you can make to the 4.0L will give you more than a handful of ponies or pound-feet. One of them is to increase the displacement via an increase in stroke. Several companies sell high-quality stroked Four-O's as complete engines or kits, most notably Hesco, Golen Engine Service, and Custom Design Performance. Engine gurus have commented that, while stroking an engine is not to be taken lightly, it ain't brain surgery on the 4.0L. We wondered if the Average Joe, capable of an engine overhaul on his own, could do the job.To find out, we enlisted the aid of the University of Northwestern Ohio (UNO) and its High Performance Motorsports program to provide the facility and manpower for the job, as well as companies known for providing great products and services to enhance the Jeep 4.0L. In this article, we'll walk you through the job of stroking the engine; we'll cover other performance mods and finish up with dyno tests next month.

Like most modern engines, the 4.0L (bore and stroke: 3.88 x 3.44 inches) is oversquare, meaning the bore dimension is larger than the stroke. The 258ci (4.2L) Jeep six (3.75 x 3.89-inch) used before the 4.0L was undersquare, meaning the bore dimension is smaller than the stroke. Generally speaking, the oversquare engine is decent at low rpm, most efficient in the middle rpm range and has good high-rpm performance. The undersquare, long-stroke engine produces the best low-end torque, has a good midrange, but is so-so on the upper end.

Increasing displacement can also come via a larger bore, but a 0.060-inch maximum overbore on the 4.0L results in an increase of only 8 cubic inches. If you install the long-stroke 258 crank into the big-bore 4.0L block, it gains 32 cubic inches and becomes almost square, with the bore and stroke the same dimension (3.875 x 3.895 inches). The usual overbore, 0.030 inch, makes it slightly oversquare at 3.905 x 3.895 inches, and it gains 34 cubes. An 0.060-inch overbore gives a 41-inch increase.

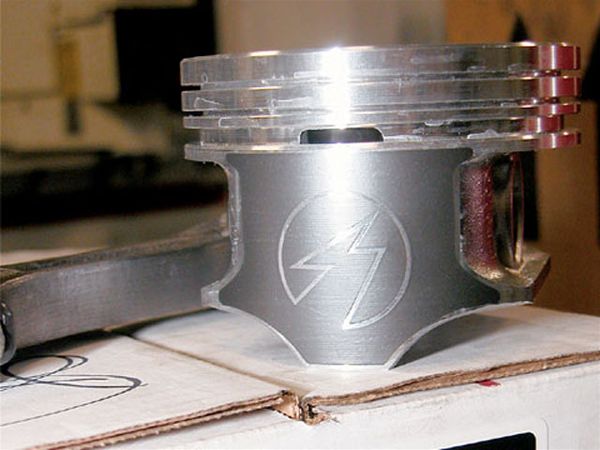

There are two roads to building the 4.0L stroker. The budget method uses a 258 crank, 258 rods (5.875-inch long), and pistons with the stock 4.0L piston pin height (around 1.60 inches.). This is called the "short-rod" engine. The more expensive "long-rod" method uses the 258 crank, the longer 4.0L rods (6.125-inch) and a shorter piston pin height dimension (slightly variable but around 1.38 inches).

While the differences in a long- and short-rod motor can be huge in a high-revving', mega-power V-8 engine, the performance differences between the long- and short-rod Jeep engines is small. That's partly the inherent design limitations of an inline-six with a long stroke, and partly the way the engines will be used. The long-rod Jeep strokers offer a somewhat broader rpm range and, in theory, the short-rod setup is subject to more wear. Frankly, we doubt the wear differences will amount to much for most of you. The rod ratio (the ratio of rod length and stroke length) of the short-rod engine is identical to the stock 258, and they were known for a long life. Because we wanted to make this an "every man's" budget stroker, offering mainly a big boost in torque in the ranges where most 'wheelers work, we stuck with the short-rod option and off-the shelf parts.

A 4.6L stroker in a TJ makes for a big performance boost, both on the street and the trail. The owner of this Jeep was relatively happy with his 4.0L's stock performance until he added big tires. Even properly geared, street performance deteriorated, and being a red-blooded, power-mad American male, he wanted more. Other than a supercharger, the stroker offers the biggest single boost in torque and power you can buy ... and all the other smaller enhancements out there just build those numbers higher.

A 4.6L stroker in a TJ makes for a big performance boost, both on the street and the trail. The owner of this Jeep was relatively happy with his 4.0L's stock performance until he added big tires. Even properly geared, street performance deteriorated, and being a red-blooded, power-mad American male, he wanted more. Other than a supercharger, the stroker offers the biggest single boost in torque and power you can buy ... and all the other smaller enhancements out there just build those numbers higher.

We learned the hard way that not all Four-O's are created equal. Our engine was destined for a 2000 Wrangler. The low-mileage original engine was being saved for another purpose, so a used engine from the early '90s was procured. We learned the hard way that there are significant external differences between the '00-and-later engines ('99-and-later for the WJ) and the earlier ones. Eye exams for all were ordered. It was as obvious as a garish Aloha shirt at a funeral. Water pumps, accessory mounting, engine mounts, induction systems, and more-all changed. Installing an older engine into a newer rig, or vice versa, involves adaptation-doable but adding to the financial burden. The best advice is to start with your original engine or a similar year range.

The biggest problems faced by 4.0L strokers is pinging (aka spark-knock or detonation) and it can be deadly to the engine. Stroker conversions end up with a higher compression ratio (CR) than stock, sometimes higher than can be supported on pump fuel. It pays to take heed of your particular combination of camshaft, pistons, head gasket, and deck height.

The static compression ratio (SCR) is simply the ratio of cylinder volume versus combustion chamber volume. Our 4.0L stroker has a total cylinder volume of 855.12 cc (52.16ci) and at top dead center (TDC, with the piston at the top), that air-fuel mixture has been squeezed into 90.59cc (5.5ci). Ergo: 855.14 90.59 = 9.44:1 compression ratio.

The dynamic compression ratio (DCR) is a more useful way to think about this. It factors the cam profile-more precisely, the intake valve closing point-with the SCR to get an operating, or "effective," compression ratio. On virtually all engines, the intake valve stays open after the point where the piston starts up on the compression stroke. Until the intake valve actually closes, compression is not occurring and the true compression stroke does not start until it does. Because the cylinder volume is reduced, so is the dynamic compression ratio. The later valve closing takes advantage of air velocity at higher engine speeds to help fill the cylinder. At low speeds, yes, that reduces the effective compression ratio, but at higher speeds the increased volume of air more than makes up for it.

1. All cleaned up with somewhere to go. All the subassemblies are ready to go and laid out for inspection. With just a few extra steps, assembling the 4.6L stroker is no different than building a standard 4.0L and a lot like any other inline-six. Unlike some stroked engines, this one offers no substantial internal clearance issues. We test-assembled these parts to check for block clearance and found no issues. Instructor Kevin Frische said, "You could drive a truck through here!"

1. All cleaned up with somewhere to go. All the subassemblies are ready to go and laid out for inspection. With just a few extra steps, assembling the 4.6L stroker is no different than building a standard 4.0L and a lot like any other inline-six. Unlike some stroked engines, this one offers no substantial internal clearance issues. We test-assembled these parts to check for block clearance and found no issues. Instructor Kevin Frische said, "You could drive a truck through here!"

2. We started with a '91-'95 block (casting No. 503008405) but switched to an '00 block (casting No. 53010449) for the reasons noted in the text. Step one was a thorough cleaning, followed by align-honing the crankshaft saddles, boring the block and honing, after which the block is thoroughly cleaned again. After this, new cam bearings were installed.

2. We started with a '91-'95 block (casting No. 503008405) but switched to an '00 block (casting No. 53010449) for the reasons noted in the text. Step one was a thorough cleaning, followed by align-honing the crankshaft saddles, boring the block and honing, after which the block is thoroughly cleaned again. After this, new cam bearings were installed.

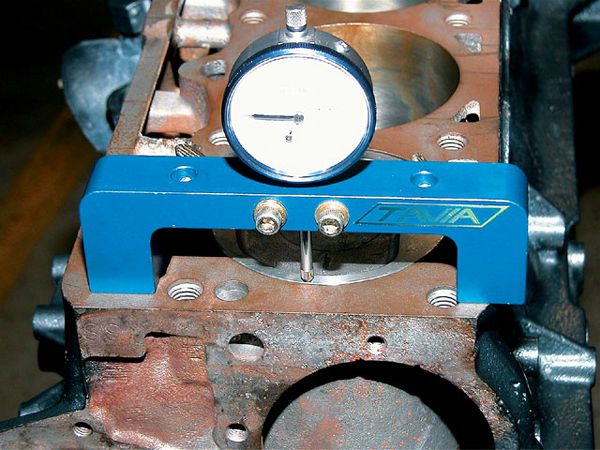

3. When we did a trial assembly of the stroker parts in the stock block, our deck clearance was 0.045 inch. We ended up removing 0.020 inch from the deck. Different aftermarket pistons have different pin heights and therefore different deck heights. Installing one piston and measuring your deck clearance to calculate the final compression ratio could save you heartaches later.

3. When we did a trial assembly of the stroker parts in the stock block, our deck clearance was 0.045 inch. We ended up removing 0.020 inch from the deck. Different aftermarket pistons have different pin heights and therefore different deck heights. Installing one piston and measuring your deck clearance to calculate the final compression ratio could save you heartaches later.

4. Decking the block isn't always necessary in a "normal" overhaul but it can be an important step with a stroker. It has to do with quench height. The best idea is to deck the block for a zero deck height and a 0.040-inch quench height, but you must increase the combustion chamber size, either by enlarging the combustion chamber in the head or increasing the piston dish size. Don't do it unless you have calculated the effects and have the right parts. Here, 0.020 inch is being removed from our block.

4. Decking the block isn't always necessary in a "normal" overhaul but it can be an important step with a stroker. It has to do with quench height. The best idea is to deck the block for a zero deck height and a 0.040-inch quench height, but you must increase the combustion chamber size, either by enlarging the combustion chamber in the head or increasing the piston dish size. Don't do it unless you have calculated the effects and have the right parts. Here, 0.020 inch is being removed from our block.

5. We were shooting for an SCR at or slightly below 9.5:1. We measured the volume of the combustion chambers in the head after porting, and the volume of the Sealed Power hypereutectic piston dish in the cylinder. You can measure the dish separately, but in the cylinder, you also see the ring land volume (generally about 1.1 to 1.3 cc). We used the thinner of the two commonly available head gaskets, and after taking about 0.020 inch off the deck for a clearance of 0.025 inch, we ended up with a 9.44:1 SCR and an 0.068-inch quench height: Less than ideal, but it saved any special machining. Had we used the thicker head gasket, we would have dropped to 9.27:1. With the cam we chose (204-degree intake duration, 26 ABDC) our DCR is calculated at 8.7:1.

5. We were shooting for an SCR at or slightly below 9.5:1. We measured the volume of the combustion chambers in the head after porting, and the volume of the Sealed Power hypereutectic piston dish in the cylinder. You can measure the dish separately, but in the cylinder, you also see the ring land volume (generally about 1.1 to 1.3 cc). We used the thinner of the two commonly available head gaskets, and after taking about 0.020 inch off the deck for a clearance of 0.025 inch, we ended up with a 9.44:1 SCR and an 0.068-inch quench height: Less than ideal, but it saved any special machining. Had we used the thicker head gasket, we would have dropped to 9.27:1. With the cam we chose (204-degree intake duration, 26 ABDC) our DCR is calculated at 8.7:1.

The big question now is, "Why does this matter?" The bottom line is that the DCR is a major factor in whether you can run on regular, midgrade, premium, or race fuel, and not ping. Also, if the DCR is too low, you will lose bottom-end torque. The generally acknowledged safe "sweet spot" is an 8.0:1 DCR for an EFI engine, and it offers good low end and a decent high end, usually on 87-octane regular. Going below 7:1 usually costs too much low-end power. With fuel injection and a good quench dimension (read on) you can sometimes reap the benefits of going higher, perhaps up to an 8.7:1 DCR on regular or midgrade. Dynamic CR above 8.7:1 almost always requires 90- or 92-octane premium. Above 9.0:1 DCR, it's almost always ping city for pump fuel. For reference, the stock 4.0L has an 8.7:1 static ratio and a calculated 8.45:1 dynamic ratio. You can download a DCR calculator from the Internet, but the Keith Black Silvolite Piston site has a good one to play with (see sources).

The formula for getting the right combination of static compression ratio and cam profile starts with selecting the cam. First, pick the maximum rpm range you need. If it's over 5,000 rpm, decide how much low-end torque you are willing to sacrifice. Seldom do 'wheelers need more than 5,000 rpm, and here's a clue: The short-rod stroker is happier below that. The cam manufacturer will usually list a maximum SCR at which the cam works best. You can double-check them by using a DCR calculator. The next step is for you to determine what parts will give you the right SCR to match. If you can't find the right mix of parts for the job, the easiest route is usually a longer-duration cam.

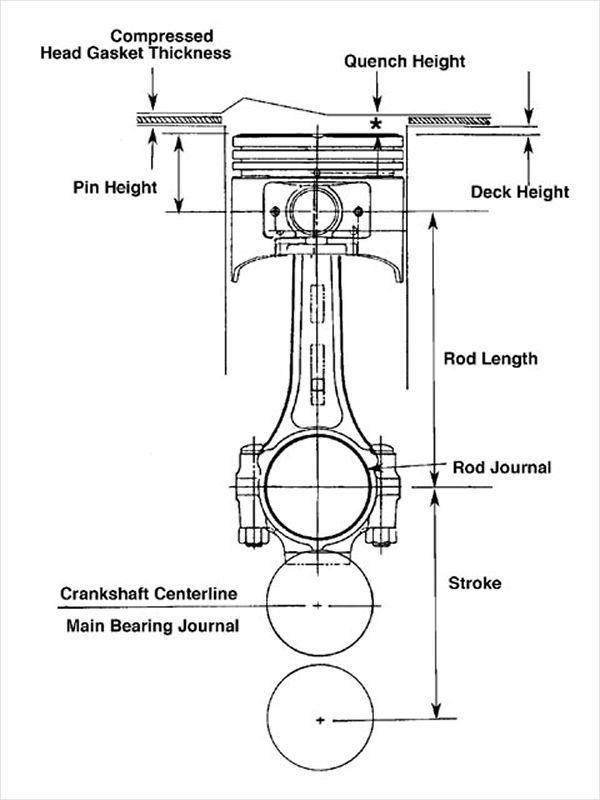

The elements that make the SCR on a stroker 4.0L are the cylinder-head combustion chamber, deck height, piston dish volume, and head gasket compressed height (see page 76). All of these are changeable, with varying degrees of difficulty, to build an SCR compatible with the cam profile and desired DCR.

You can grind out material from each combustion chamber to increase the head volume but you must be able to measure that volume via the procedure called "cc-ing" and make each combustion chamber the same volume. Ditto for the piston dish, which varies by aftermarket manufacturer, but which can be ground out slightly to increase its volume. See the sidebar below for some common piston dish specifications.

Head gasket thickness seems like one easy way to adjust compression ratio, but compressed gasket thickness can be difficult to determine exactly. In the high-performance gasket realm, the compressed thickness is listed and the manufacturers stand by those numbers. The standard gaskets are less controllable. The range runs from about 0.040 to 0.055 inch on the commonly available 4.0L gaskets. A rule of thumb for the 4.0L stroker is that with a 4-inch gasket bore, an 0.010-inch change in head gasket thickness equals a change of about 0.180:1 in CR.

You can get a rough idea of what your compressed dimension will be by measuring the thickness of the gasket body (not the flame ring around the bore or sealing strips imprinted on the body) and deduct about 0.005 inch. This applies to the gaskets advertised as "permanent torque" or "no-retorque." Cheaper gaskets that require retorquing can compress two to three times that much and are less predictable. Bottom line, you cannot say with certainty that X gasket has Y thickness unless it's a performance gasket that has a listed specification.

Quench is the "Great Equalizer" when it comes to a high compression ratio. The quench area is the area between the highest flat spot on the piston and the lowest part of the roof of the combustion chamber. Less quench distance induces more turbulence in the combustion, which promotes better fuel mixing and fewer hot spots-all of which reduce pinging. Many experts think that 0.040 to 0.045 inch of quench is ideal, but without making other changes, decking the block for zero deck height (removing about 0.045 inch) will increase the static compression ratio to about 9.7:1 with the standard combustion chamber, an 0.052-inch head gasket and largest available 4.0L piston dish volume (18.83 cc). If you put in a 218-degree cam (intake at 0.050 inch, 36 ABDC), the dynamic ratio is about 8.56:1, and most experts consulted agree that this engine would run on midgrade, maybe even regular, with timing and EFI adjusted to optimal power settings.

6. After boring 0.030 inch, the cylinder walls were tested with a Dakota Instruments ultrasonic micrometer. The rule of thumb is that you need approximately 0.200 inch (just over 3/16-inch) of cylinder wall left to support the stresses of a performance engine. A low-po engine can get by with less, perhaps around 0.150 to 0.180-inch. Our metric block tested to an average of 0.250 to 0.270 inches on all cylinders.

6. After boring 0.030 inch, the cylinder walls were tested with a Dakota Instruments ultrasonic micrometer. The rule of thumb is that you need approximately 0.200 inch (just over 3/16-inch) of cylinder wall left to support the stresses of a performance engine. A low-po engine can get by with less, perhaps around 0.150 to 0.180-inch. Our metric block tested to an average of 0.250 to 0.270 inches on all cylinders.

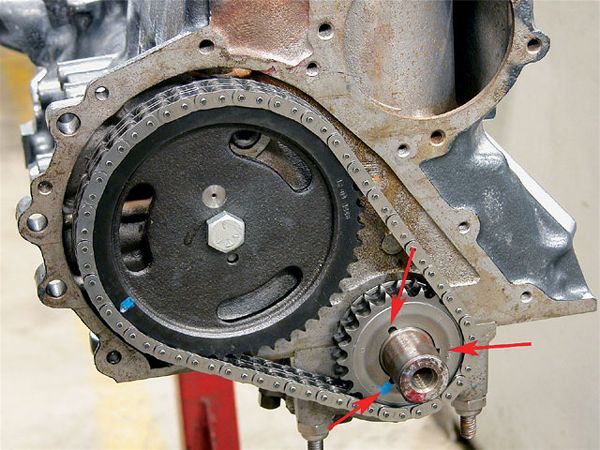

7. The 258 crankshaft bolts into the 4.0L block with no trouble. We used the latest 258 crank, the '87-'90 model (casting No. 3727). This is an 8-counterweight version that is compatible with serpentine belts. Earlier cranks have a longer snout and require a spacer (Hesco makes 'em) for pulley alignment. Especially important to manual transmission users, the 258 and '87-'91 4.0L cranks have a larger pilot bushing outer diameter (OD) than the '92-'06 4.0L engines. We used a bushing that had a 1.82-inch OD and 0.75-inch inner diameter (ID) found at a parts store. It fits into the larger bore at the end of the crankshaft. There are other possible dimensions depending on which trans you have, so pay attention.

7. The 258 crankshaft bolts into the 4.0L block with no trouble. We used the latest 258 crank, the '87-'90 model (casting No. 3727). This is an 8-counterweight version that is compatible with serpentine belts. Earlier cranks have a longer snout and require a spacer (Hesco makes 'em) for pulley alignment. Especially important to manual transmission users, the 258 and '87-'91 4.0L cranks have a larger pilot bushing outer diameter (OD) than the '92-'06 4.0L engines. We used a bushing that had a 1.82-inch OD and 0.75-inch inner diameter (ID) found at a parts store. It fits into the larger bore at the end of the crankshaft. There are other possible dimensions depending on which trans you have, so pay attention.

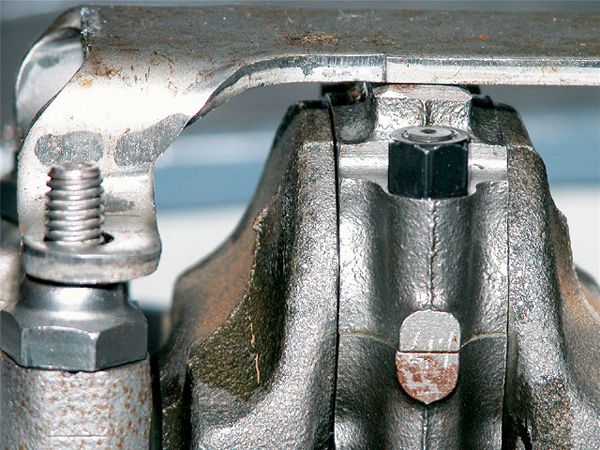

8. You can buy crankshaft kits from many sources if you can't find a used one to recondition yourself. Unless you have an '87-'90 (non-H.O. block), however, don't buy a 258 crank kit because the main bearings will be incorrect for the '91-and-later blocks. The 4.0L blocks use a bearing with the dovetail (see arrow) centered in the saddle. The 258 and early 4.0L have the dovetail offset.

8. You can buy crankshaft kits from many sources if you can't find a used one to recondition yourself. Unless you have an '87-'90 (non-H.O. block), however, don't buy a 258 crank kit because the main bearings will be incorrect for the '91-and-later blocks. The 4.0L blocks use a bearing with the dovetail (see arrow) centered in the saddle. The 258 and early 4.0L have the dovetail offset.

9. We used the 707 casting 258 connecting rods (5.875-inch length), really the only ones commonly available for the 258. We found that you can buy reconditioned rods via various outlets. We also replaced the stock bolts with aircraft-grade bolts from ARP.

9. We used the 707 casting 258 connecting rods (5.875-inch length), really the only ones commonly available for the 258. We found that you can buy reconditioned rods via various outlets. We also replaced the stock bolts with aircraft-grade bolts from ARP.

10. From '96, 4.0L engines used a main bearing girdle for more overall strength. This is something that can be added to any earlier 4.0L by replacing the main bearing cap bolts and getting the girdle...

10. From '96, 4.0L engines used a main bearing girdle for more overall strength. This is something that can be added to any earlier 4.0L by replacing the main bearing cap bolts and getting the girdle...

...The longer throws on the 258 crank, however, will let the rods interfere with the girdle. The solution is simple-add a couple of hardened washers to space the girdle down a quarter inch or so.

...The longer throws on the 258 crank, however, will let the rods interfere with the girdle. The solution is simple-add a couple of hardened washers to space the girdle down a quarter inch or so.

Calculated, not observed. The volume dimensions are averages, not absolutes. The only way to know for sure is to test your parts.

*Note: This piston dish is commonly listed as 17.5cc. The number shown is our measured amount, including ring land volume (about 1.3cc)

** The Golen Engine. Piston dish estimated from advertised compression ratio.

SP= Sealed Power, KB =Keith Black Silvolite, OE= Original Equipment

Bold text indicates the setup used for the UNO engine.

Bold text indicates the parts used in the UNO buildup.

To Get Deck Height (DH)

deck height = block height* - rod length - piston pin height - 1/2 stroke

To Get Compression Ratio (CR)

CR = total cylinder volume combustion chamber volume

To Get Combustion Chamber Volume (CCV)

CCV = cyl head volume + head gasket volume + deck clearance volume + piston dish volume

To Get Cylinder Volume (CV), Deck Clearance Volume or Head Gasket Volume

CV = 0.7853942 x bore2 x stroke

Note: For head gasket, used compressed distance.

To Get Quench Height (QH)

QH = deck height + head gasket compressed distance

*Block height = Distance from crankshaft centerline to block deck On a 4.0L= 9.450-9.456-inch