The GM HEI (High Energy Ignition) electronic distributors have a reputation for hassle-free performance. Used in GM rigs from its inception in 1974, the famed HEI can be retrofitted to almost any GM engine for a dramatic improvement over a point-style distributor. However, their moving parts do wear over time, and additional power can literally be locked under the cap-even in fresh, factory-spec HEIs.

To explain this in simplistic terms, an engine's piston travels faster than the spark, so, the spark needs a head-start (or advance) to arrive at the proper time for optimal combustion. Inside the head, the rate that the flame moves across the combustion chamber is affected by compression ratio, turbulence of the air/fuel mixture, spark-plug indexing, design of the combustion chamber, and other factors. A killer spark is usually needed for optimum combustion and maximum power.

In engines with an HEI distributor, variable ignition timing is controlled by engine vacuum advance and centrifugal advance. Vacuum is usually consistent in vehicles that have safe-and-sane cam profiles, whereas lumpy cams transfer the bulk of the timing burden to the centrifugal weights. In other words, all of this means that optimizing spark advance is often trial and error.

Professional distributor curving is now almost a lost art. But four-wheelers who like to tinker can tune their HEIs at home-or even in the boonies as part of trail-testing.

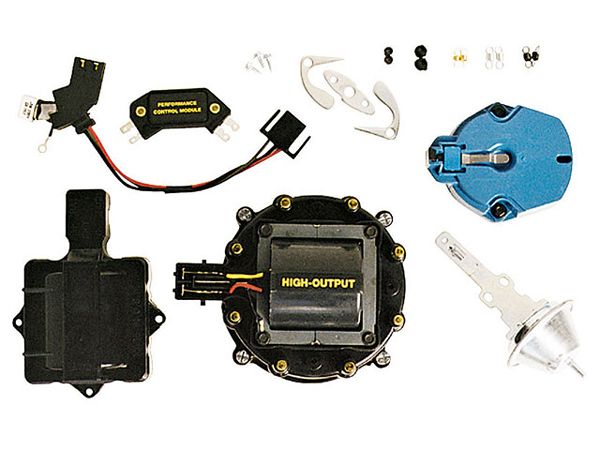

Inside an HEI, replacement springs and weights are available to control the centrifugal advance, and adjustable vacuum-advance canisters allow part-throttle spark timing to be tuned. Proform, a company that introduced the HEI Tune-Up Kit (PN 66945) some years ago, includes various weights and springs in the aforementioned kit; these items are also available la carte in an HEI Advance Curve Kit (PN 66948C) for people who don't need a cap, pickup coil, module, rotor, condenser, capacitor, wiring harness, and adjustable vacuum advance (available separately as PN 66952C).

Complete HEI rebuild kits include a new coil and dust cover, cap, rotor, control module, vacuum advance canister, bushings, wire harness and capacitor, spring-and-weight set and new mounting hardware. Distributor caps are also available in different colors.

Complete HEI rebuild kits include a new coil and dust cover, cap, rotor, control module, vacuum advance canister, bushings, wire harness and capacitor, spring-and-weight set and new mounting hardware. Distributor caps are also available in different colors.

Most people generally don't attempt to fix what ain't broke. However, a dead distributor or tune-up time offer opportunities to tweak the spark without breaking much of a sweat.

The decisive factor is often the existing HEI's shaft assembly. If any of its components are worn, you're better off replacing the distributor or sourcing a rebuildable core. Aftermarket distributors often have upgraded components, all of which can be purchased separately and transplanted onto an OE assembly for 'wheelers who feel they don't need a fancy billet housing. Most notable are 50,000-volt coils (for better burn than the OE 35,000-volt models), low-saturation ignition modules for increased spark intensity, high-dielectric caps with brass terminals for better conductivity, no-arc rotors, and hardened distributor gears.

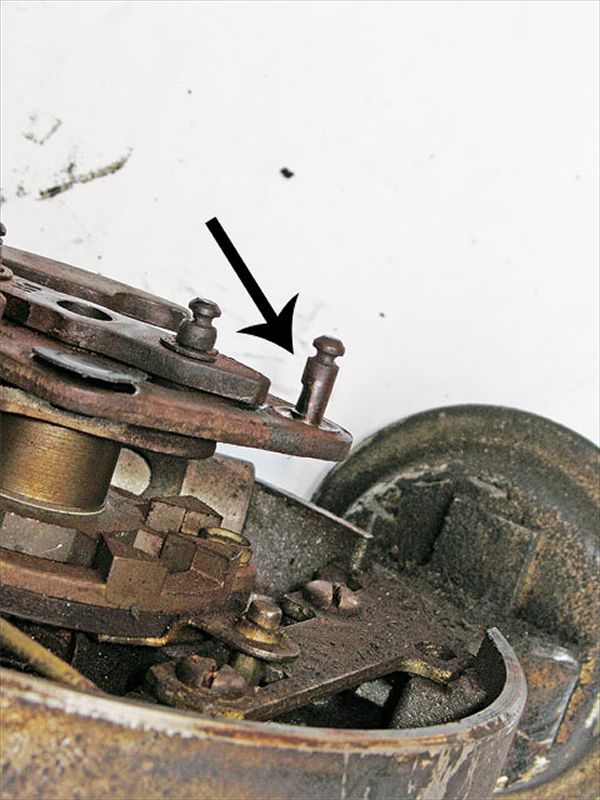

Before rebuilding, make sure the shaft assembly is sound. This weight post is notched from wear (arrow), making this core not rebuildable. Although it could work, the tension on the springs would not be accurate, nor would the centrifugal weight move smoothly or consistently.

Before rebuilding, make sure the shaft assembly is sound. This weight post is notched from wear (arrow), making this core not rebuildable. Although it could work, the tension on the springs would not be accurate, nor would the centrifugal weight move smoothly or consistently.

For tunability, Proform offers both its Curve Kit and complete new billet HEIs in a choice of three factory-curved versions: heavy vehicles (high-load, low-vacuum cam), medium vehicles (short-duration, high-torque cams-best for 4x4s) and light vehicles (race cams). Highlights of both options are shown here.

On its adjustable vacuum-advance units, Proform factory-sets the canister at 15 degrees, which works well for a variety of applications. Each full counterclockwise turn subtracts 2 degrees.

Obviously, the best way to find and document hidden power is on the dyno. However, wheelers who like to diddle with their HEIs can likely feel some extra poop by fine-tuning the centrifugal and vacuum spark advances.

Distributor guts are available as kits or individually from Proform and other aftermarket sources. If rebuilding, first verify that the core is good. Usually, shaft problems doom a distributor, but the other components can be easily replaced and upgraded. Bench-building is more convenient, but the job could theoretically be done in the field, even with the HEI still installed on the truck.