What are the most desired performance characteristics for a Jeep engine? If we took a survey, the list would probably look something like this: 1. Instant throttle response and resistance to stalling. 2. A usable rpm range from idle to 4,500 rpm, with loads of torque. 3. Stock or better fuel economy.

If the 4,500 rpm figure sounds low, conduct your own survey and count the number of times in a month you exceed 4,500 rpm. If it's more than just a couple times a month, then you're either running a competition rig or are a dedicated lead-foot.

The fact is, most off-pavement driving is done slowly, sedately, and under 3,000 rpm, unless you're in the mud, cinders, or sand. Spirited driving usually takes place on the street from stoplight to stoplight. Even then, 4,500 rpm is rarely exceeded. What launches your Jeep so nicely is torque, and if you tell the truth, it's that nice launch you want during those moments of leadfootedness.

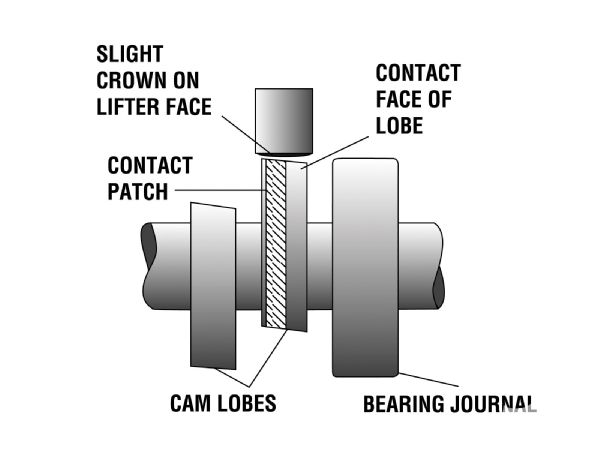

Though it's hard to detect with the naked eye, the lobes of the cam are ground on a 0.001-inch taper, and the lifter faces are slightly convex, or crowned. These features improve wear characteristics and cause the lifter to rotate. A lifter that stops rotating will soon fail.

Though it's hard to detect with the naked eye, the lobes of the cam are ground on a 0.001-inch taper, and the lifter faces are slightly convex, or crowned. These features improve wear characteristics and cause the lifter to rotate. A lifter that stops rotating will soon fail.

A replacement cam is near the top of many Jeepers wish lists, but would you believe that most factory cams can equal aftermarket cams in dyno tests of torque up to about 2,500 rpms? The stock cam exhibits most of the desirable characteristics listed above. Here's a reality check for you. Unless you need a new cam or plan a lot of other engine mods, the stock cam is a cost-effective choice.

Making a Cam Choice

Even simple nonengine factors can affect your cam choice. Gearing and tire size are two factors that immediately come to mind because they can change the operating rpm of your engine. Why is this important? If you use your Jeep everyday, fuel economy is probably of some importance. An engine is most fuel efficient near the middle of its torque range. The ideal range is dictated by the cam profile. Cam manufacturers often give an ideal cruise rpm. If you select a cam to match your freeway cruising speed, economy will peak where you want it.

The power and torque curves for a given cam change inversely proportional to engine displacement. The rpm range drops slightly as the displacement increases. In engine families that have an interchangeable cam, such as the 290-401 AMC V-8, a cam that's smooth and docile in a 401 might turn a 304 into a low-rpm gutless wonder. If your engine is at the small end of the displacement range for a particular cam, a conservative choice gives better torque results.

Once the selection has been made, these are the parts needed: cam, lifters, and matching valve springs. Always use matching parts from the same manufacturer for best results. Pennies you save now may later cost you dollars.

Once the selection has been made, these are the parts needed: cam, lifters, and matching valve springs. Always use matching parts from the same manufacturer for best results. Pennies you save now may later cost you dollars.

Generally, a replacement cam with close-to-stock duration, but with a bit more lift, will offer more torque. If you open the valve more, it's logical that more fuel and air can enter, and more exhaust can escape. The nice part is that the extra lift won't cost fuel economy, but there is a practical limit. Between 0.450 inch and 0.500 inch, valve lift is the upper limit for most engines with an unmodified valvetrain.

The amount of time the valve is open, (duration) is even more important. The longer the valve is open, the more air and fuel the engine can take in. This is conducive to high-rpm power production, but at low speeds, the traditional long duration cam will effectively kill low-end grunt. Wider lobe-center angles can lessen this detrimental effect, and you can have some benefit of a longer duration without all the bad side effects.

Duration and compression ratio also have an important relationship. A short-duration cam combined with a high-compression ratio may increase cylinder pressure enough to cause pinging. Conversely, a longer-duration cam with a low-compression engine will be a slug due to a lower effective compression ratio.

The cam manufacturer will often have a compression ratio recommendation. If your engine has a ratio between 8.6 and 9.5:1, your available cam choices will allow for a pretty flexible rpm range. If you have a very low-compression engine, 8.0 to 8.5:1, you'll need to stick with short-duration cams and will probably have to sacrifice some upper-end power to keep cylinder pressures up. For high-altitude operation, a shorter-duration cam usually works best.

Matching the Induction System to the Cam

A factor to keep in mind when selecting a cam is the engine's ability to breathe. If you've significantly improved the intake or exhaust system, the original cam profile may not be able to use those improvements. It's still trying to compensate for the original intake or exhaust limitations that no longer exist. Conversely, the stock induction and exhaust system may hinder the new cam's potential benefits. Plan ahead and match the cam to the complete engine.

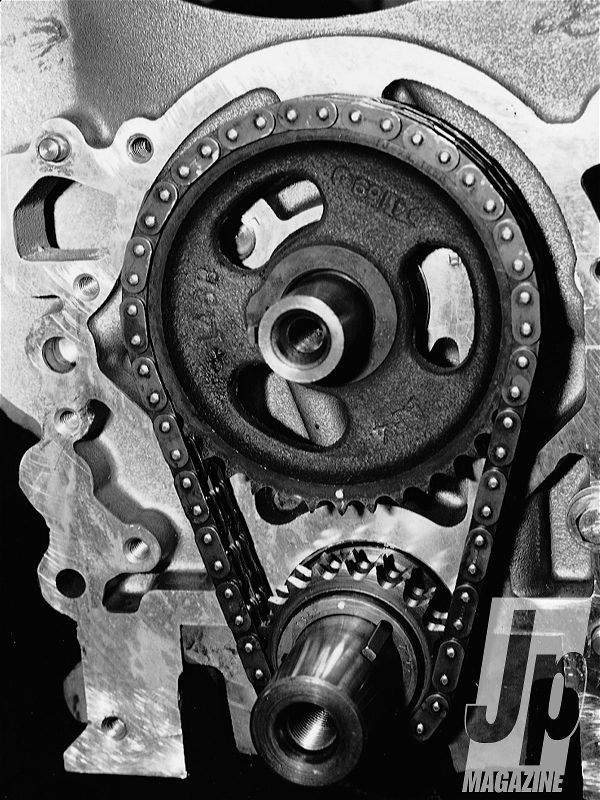

A Cloyes True Roller timing chain set like this is a cost-effective investment in long-term cam-timing accuracy. It has three keyways: one at the standard setting, one at 4 degrees advanced, and one 4 degrees retarded, to broaden your cam timing options.

A Cloyes True Roller timing chain set like this is a cost-effective investment in long-term cam-timing accuracy. It has three keyways: one at the standard setting, one at 4 degrees advanced, and one 4 degrees retarded, to broaden your cam timing options.

Overcarburization is a common mistake. If you combine a moderate-duration cam that generates good idle vacuum with a Godzilla four-barrel, your puny V-8 will fall flat on its face when the throttle is open. If you put in more cam than the carb can handle, the engine runs out of airflow just as the cam gets going strong.

For Jeeping purposes, the carburetor or fuel-injection systems on most stock engines are usually decent in terms of capacity. The average factory V-8 2bbl flows about 450 cfm. The average 4bbl runs about 600 cfm. Either way, that's theoretically more than enough airflow to rev a 360 past 5,500 rpm. The EFI systems on the later engines have a similar capacity. That doesn't mean you have to stick with OE induction if your local emissions laws allow changes, but consider that what you have may not be that bad.

Your cam choices may narrow considerably with EFI engines. They're extra-sensitive to changes in engine vacuum. Choose a cam that maintains stock or near-stock idle vacuum, or be prepared to spend some hefty bucks recalibrating the EFI. The cam manufacturers can recommend a bumpstick that will minimally impact your EFI setup.

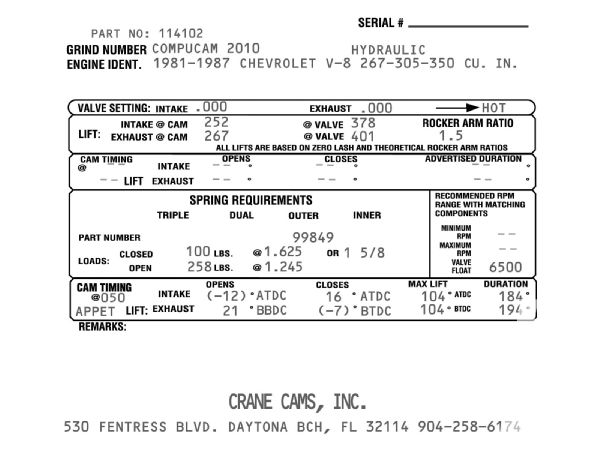

Your new cam will come with a card similar to this that details the specifications to the nth degree. You can use it for general information or for fine-tuning.

Your new cam will come with a card similar to this that details the specifications to the nth degree. You can use it for general information or for fine-tuning.

Cam Tuning

Altering cam timing is one way to enhance engine performance, but it's often a trial-and-error process. In general, advancing cam timing moves the power curve lower, and retarding it moves it higher. That's more effective when enhancing a stock cam than aftermarket cams, since the aftermarket guys usually factor in a little timing advance beforehand.

The best reason to alter cam timing is to correct timing errors caused by manufacturing tolerances in the parts involved. It isn't uncommon to check the cam timing with new replacement parts (especially no-name and el cheapo specials) and find errors of 5-8 degrees. If you ever wondered why two identical engines perform at opposite ends, this is one of the reasons.

If you do need to alter cam timing, it can be done several ways, depending on your engine. One way is with offset camshaft-to-cam gear keyways, which can be bought in 2- to 8-degree increments, or with offset dowel pins, which advance or retard cam timing. Also, Cloyes, Crane, and others make a double roller chain and steel gear set with three keyways cut at three different timing increments.

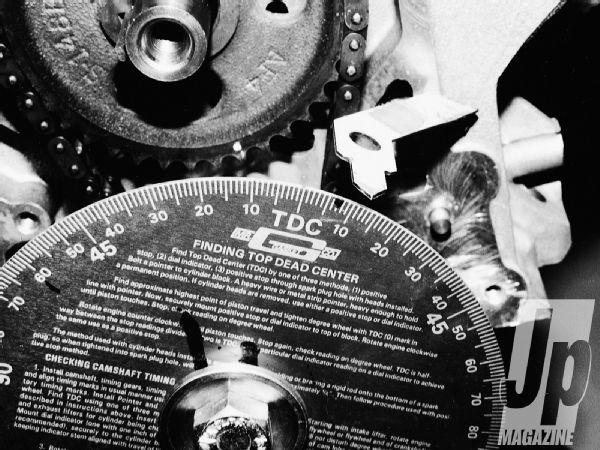

Degreeing the cam isn't brain surgery, but it is tricky. It can be valuable in tweaking those last few pound-feet from your engine or making sure you aren't losing anything to machining errors. These errors are unusual in high-quality parts, but if you buy the cheap, no-name stuff, you can find errors of up to 8 degrees. You can buy cam degreeing kits from most big cam grinders.

Degreeing the cam isn't brain surgery, but it is tricky. It can be valuable in tweaking those last few pound-feet from your engine or making sure you aren't losing anything to machining errors. These errors are unusual in high-quality parts, but if you buy the cheap, no-name stuff, you can find errors of up to 8 degrees. You can buy cam degreeing kits from most big cam grinders.

Altering rocker arm ratios is an easy (in theory) method of increasing lift. By increasing the rocker ratio from 1.6 to 1.75 on a 0.250-inch-lift cam, valve lift could increase from 0.400 inch to 0.437 inch. Depending on the engine, this can be a cost-effective mod.

FACTORY JEEP CAM SPECS 1946-1998 Engine Lift (inch)* Duration (degree)* Overlap Intake/Exhaust Intake/Exhaust (degree)**Caminology: Speak The Lingo

Duration: The amount of time in crankshaft degrees that the valve is off the seat. Advertised duration measures this period from the time the valve is 0.004 inch to 0.006 inch off the seat. A more useful method measures the duration from 0.050-inch lift, since no useful airflow occurs until this point.

Lift: Expressed two ways: valve (or gross) lift or cam lift. Cam lift is the maximum amount, in thousandths of an inch, the cam lobe moves the lifter. Valve lift is the maximum amount the cam and valvegear together move the valve.

Lobe Center: The very center of the peak lift area of the lobe. The peak lift period could be as long as 5 degrees, with the lobe center the exact middle of it.

Lobe Separation Angle: The distance in degrees between the intake and exhaust lobe centers. This is a more accurate way to express the overlap period when both the intake and exhaust valves are open. By spreading the lobes farther apart, the overlap period is decreased and low-rpm power is enhanced. Narrowing the lobe centers has the opposite effect. Wide angles are 112-118 degrees, and narrow angles are 105-110 degrees.

Overlap: A period in the four-stroke cycle when both valves are partly open. It's a beneficial moment because the outgoing flow of exhaust helps to draw a fresh charge into the cylinder. This helps to fill the cylinder with a fresh mixture and purge the exhaust. How much overlap you want is proportional to the intended rpm range. Too much causes a loss of idle vacuum and low-rpm torque; too little hampers higher-rpm power.

Rocker Ratio: Altering the pivot points of a rocker arm can multiply the cam lift. Stock rocker ratios vary from 1.4:1 to 2:1. Increasing your rocker ratio may benefit torque production. Exchanging a 1.5:1 rocker for a 1.6:1 unit increases lift by just under 10 percent.

Single and Dual Pattern Cams: A single-pattern cam has identical lobes on the intake and exhaust. A dual-pattern cam has different lobe designs for each. Many engines have problems with flow on the exhaust side, so the exhaust duration is lengthened, and lift is increased over the intake profile. Sometimes the opposite is true.

Symmetrical and Asymmetrical Cams: A symmetrical cam would have the same shape or profile on the opening ramp of the lobe as the closing ramp. This was the industry standard for many years. With computer technology, it's now possible to have different shapes and rates on the opening and closing ramps of the lobe. It might be beneficial for a particular engine to have a steep, fast opening rate, but a gentle closing rate to avoid slamming the valve closed.

Recommended RPM Range: Depending on the manufacturer, these figures may give the most efficient rpm range, i.e., maximum torque, or the minimum and maximum rpms for a particular camshaft. Specs may also include the ideal cruising rpm speeds. These figures are important in the cam selection process. If the cam is rated for max torque at 3,000-7,000 rpm, you don't want to put it into a vehicle used at 1,500-3,000 rpm. The cruising rpm figure is a bonus because you can pick a cam that has max economy at your best cruising speed.

PhotosView Slideshow