Pete Trasborg

Brand Manager, Jp

Pete Trasborg

Brand Manager, Jp

It was either going to be one of the best modifications we’d ever done to this Jeep or one of the worst. There was no middle ground here. We really like the front coil, rear leaf spring architecture of the XJ Cherokee suspension. The front coils flex like mad off-road and provide a great ride on- and off-road. Out back the rear leaf springs’ inherent internal friction means we can disconnect the front sway bar and still feel stable on side hills. And, our custom junkyard packs flexed really well for leaf springs and provided an overload leaf that allowed us to haul parts in the back.

As capable as our ’98 Cherokee was, it still wasn’t as good as a TJ, LJ, or JK. It wasn’t quite as comfortable on-road, and we just couldn’t keep up with the Joneses off-road either. But, it was armored, locked, and all the bells and whistles still worked. It basically came down to whether we wanted to put a bit more cash into our trusty Cherokee or start looking for another platform to build.

This isn’t our first rodeo. One of the reasons we custom-built our junkyard leaf pack was because all the off-the-shelf lift springs we’ve run over the years were too stiff for our tastes. So, we built the pack with a combination of Cherokee, Comanche, YJ Wrangler, and Toyota leaf springs to get us about 31⁄2 inches of lift. The next step up from there would be custom aftermarket leaf springs. But they can cost up to $1,000 and the rear of the Jeep would still come around on us on loose or rutted roads and we’d lose our cargo-carrying capacity.

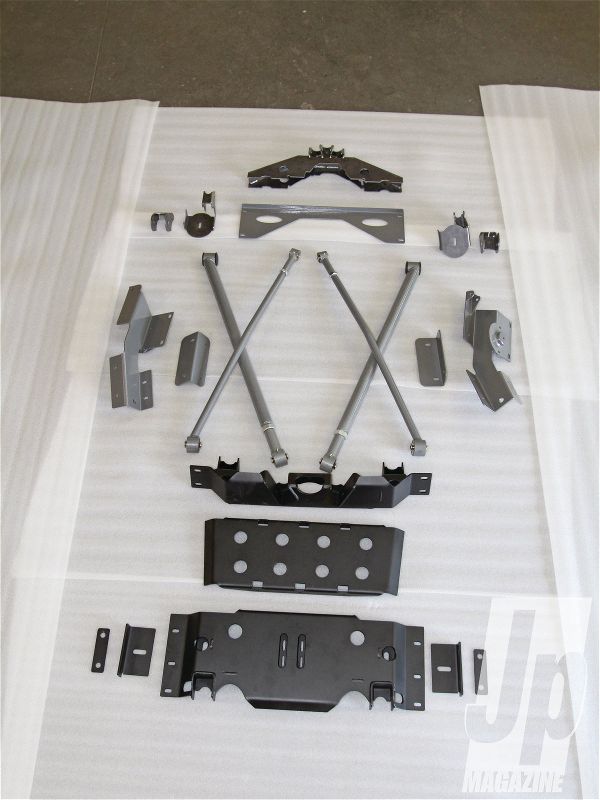

We had T&T put the kit on our Jeep for the insider’s tips and tricks and (to be honest) the install seemed a real bear to pull off in the driveway. In reality, it was easier to put this kit on our Cherokee than basically every TJ long-arm conversion we’ve done. Don’t fear doing this one at home. Shown is the rear dual-triangulated kit that we put on our Jeep. All the parts above the dashed line can be had for around $1,500 depending on what options you go with. The part below the line is the belly skidplate that we already had; it’s shown here so you can see how the new parts match up with the old.

We had T&T put the kit on our Jeep for the insider’s tips and tricks and (to be honest) the install seemed a real bear to pull off in the driveway. In reality, it was easier to put this kit on our Cherokee than basically every TJ long-arm conversion we’ve done. Don’t fear doing this one at home. Shown is the rear dual-triangulated kit that we put on our Jeep. All the parts above the dashed line can be had for around $1,500 depending on what options you go with. The part below the line is the belly skidplate that we already had; it’s shown here so you can see how the new parts match up with the old.

Like many of your Jeeps, this one has been modified slowly over the years as the factory parts die or as circumstances required. One of the first modifications we made to this Jeep was a set of T&T Customs chassis stiffeners. We knew this Jeep was going to see a lot of off-road miles and we wanted to try and keep the Unitbody together. Then when it came time to take it to Moab we added T&T’s Bellypan to protect our AW4 and NP242 from the slickrock. Later, when our factory front control arms and bushings were twisted and dry rotted, we added T&T’s long Y-link arms. Our Dana 44 rear axle was bought used for $300 with T&T’s truss already on it. So when the time came to improve on leaf springs we started looking at T&T’s rear coil conversion.

The problem was, as sold, the coil conversion provides 51⁄2 inches of lift, and we wanted to stay at 31⁄2 inches. It also deletes the rear sway bar and we were kind of leery about wheeling (specifically side-hilling) with coils at all corners and no sway bars. After talking with the company, we figured out that we could stay low by using used LJ coils and used JK Rubicon shocks, both of which we already had. So, all told it was going to be just under $1,500 in parts to coil-convert the rear of our Cherokee.

This was the last wheeling trip for our faithful Cherokee before we put it under the knife and ditched our trusty rear leaf springs. At this point we still didn’t know if we were going to love the change or hate the change, so we fought a driver’s door that didn’t really want to open in order to get out and snap a few pictures of it crossed up for posterity. Tune in next time for our ride and abuse evaluation.

This was the last wheeling trip for our faithful Cherokee before we put it under the knife and ditched our trusty rear leaf springs. At this point we still didn’t know if we were going to love the change or hate the change, so we fought a driver’s door that didn’t really want to open in order to get out and snap a few pictures of it crossed up for posterity. Tune in next time for our ride and abuse evaluation.

Even though we’d ridden in a Cherokee with the T&T rear coil conversion, it was a short ride. Living with something is a lot different than just riding in it for a short time, but we knew that leaf springs weren’t going to give us what we wanted out of this Jeep. And, if anyone is going to give you an honest opinion on how a suspension works it is going to be us. So, in an effort to improve our Jeep and give you guys an honest review, we went ahead and took the plunge. For more on how it works, check out the story “Hit It Big” in this issue.