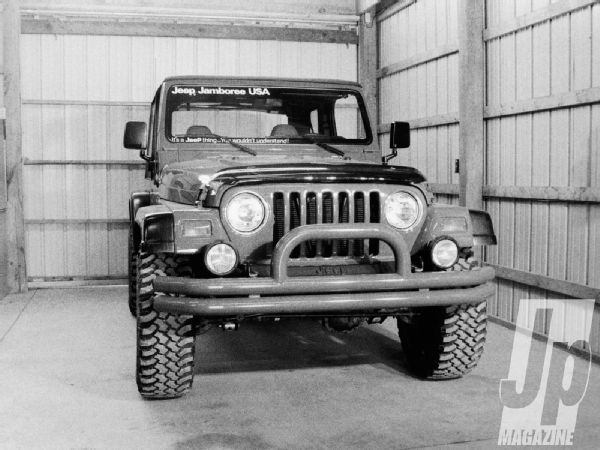

It seems like a short time ago that Jeep was heralding the introduction of a new and redesigned Wrangler for 1997. The changes to the YJ platform were the subject of much discussion among SUV enthusiasts everywhere.

Most folks had comments and questions about everything from the initial offering of airbags to the return to round headlights, but the one topic that generated the most interest among our trail-riding brethren was the quad-coil suspension. Many die-hard purists initially felt that once again off-road ability was being sacrificed for on-road handling.

The Rancho kit comes with everything needed, including a detailed instruction manual with illustrations and photos.

The Rancho kit comes with everything needed, including a detailed instruction manual with illustrations and photos.

Our first testdrive was in a fully equipped 4.0L, five-speed model. The test trail at Performance Off-Road includes rockcrawling, hill climbing, and a goodly amount of mud. We admit to being quite pleasantly surprised at the capabilities of the TJ on all types of terrain and in all kinds of situations. On- and off-road, the TJ continued to impress and led us anxiously in pursuit of even greater vehicle performance.

We decided to start with a Rancho Suspension lift kit. The 2 1/2-inch kit provides everything necessary to completely upgrade the entire system. Four new coils provide the lift, and heavier lower suspension arms equipped with poly bushings and zerk fittings handle the locating chores. The taller coils require longer shocks, so the kit contains four Rancho RS9000 adjustable shocks. Also included: a transfer case skidplate relocator kit, a track-bar relocator assembly kit, a shift relocator kit, bumpstop spacers, and comprehensive, illustrated instructions. The instruction booklet suggests an installation time of six to eight hours. What follows is the step-by-step installation process.

Installation prep includes lubricating the urethane bushings and sleeves and installing them in the suspension arms. Support the vehicle on jackstands.

TALE OF THE TAPE

ANGLES

Stock Suspension

Rancho Suspension

AND CLEARANCES

with 31/10.50 Tires

with 33/12.50 Tires

Approach Angle

43 degrees

52 degrees

Departure Angle

25 degrees

34 degrees

(due to low receiver hitch)

(same hitch)

Front Differential Clearance

9.25 inches

10.75 inches

Rear Differential Clearance

9.25 inches

10.75 inches

Skid Plate Clearance

9.75 inches

12.75 inches

PhotosView Slideshow

Installation prep includes lubricating the urethane bushings and sleeves and installing them in the suspension arms. Support the vehicle on jackstands.

TALE OF THE TAPE

ANGLES

Stock Suspension

Rancho Suspension

AND CLEARANCES

with 31/10.50 Tires

with 33/12.50 Tires

Approach Angle

43 degrees

52 degrees

Departure Angle

25 degrees

34 degrees

(due to low receiver hitch)

(same hitch)

Front Differential Clearance

9.25 inches

10.75 inches

Rear Differential Clearance

9.25 inches

10.75 inches

Skid Plate Clearance

9.75 inches

12.75 inches

PhotosView Slideshow