Jerrod Jones

Former Editor, Off Road

Jerrod Jones

Former Editor, Off Road

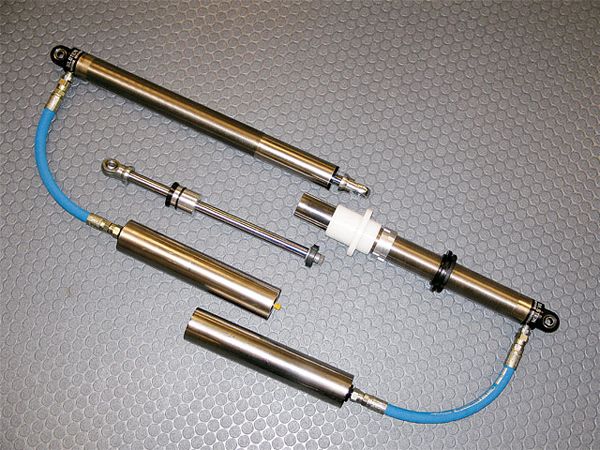

Last month we covered the basics about rebuilding your coilover shocks, but we just flat ran out of room before we got to anything about the coils on those shocks. The beauty of the coilover is in thecoil-carrying capacity of the shock. It's adjustable, easily replaceable, and easily tunable. Since the coilover shock only has the duties of supporting the vehicle's weight and absorbing the inconsistencies in the road, you can finely tune your coils and shock to give you the utmost performance out of your suspension. The coils are readily available in different spring rates and are universal to a 2-, 2.5-, or 3-inch-diameter shock body, on almost any manufacturer's coilover shock. This way you can just step into your local off-road shop and buy the coils you want right over the counter. No custom coil orders, just easy-to-drop-in coils at about a hundred bucks a pop.

Coils

Hopefully you'll never have to do any coil maintenance, and if you do, it will be picking them up and throwing them in the trash (or making a nice ashtray out of 'em for your mom). Coils either work or they don't. They can wear out over time, but you'll notice them getting a little soft, and you'll hopefully realize that a new coil is in order. You can prematurely kill the spring rate of the coils by collapsing them to the point when the coil winds touch. Once this happens, the coils have now been stressed to the point when their labeled spring rate will no longer apply. Most coilover shocks are dual-rate coilovers, meaning they use two differently rated coils to come up with an initial spring rate. There are some triple-rate coilovers we've seen, some custom single coils, and some that use keeper coils (almost zero-rate coils that basically hold the other coils in place during full shock extension). But for all intents and purposes, we're covering dual rates, and most other configurations are similar enough that you can make the connection in your head.

Dual-rate coilovers give the advantage of allowing you a net (initial) rate to ride around on, but upon clapout of the upper secondary coil, progress into a stiffer second spring rate (the sole rate of the lower primary coil). The primary coil sits on the lower coil plate of the shock, with a spring slider that divides the main coil and upper secondary coil. As the shock compresses, so will the coils, until a point where the slider/divider will be stopped by the slider stop ring. You'll need to make sure you set the slider stop ring to a point where it stops the upper coil's compression before it is fully collapsed. Once the slider has stopped, the upper coil is no longer part of the spring rate and the rest of the spring compression is placed on the lower primary (stiffer) coil, therefore boosting the spring rate to whatever the lower coil's rate is.

Confused? Two differently rated coils make up one single rate when stacked. And it's not as simple as adding them together. Even two 250-pound rate coils stacked on top of each other do not equal a 250-pound spring rate.

Here is a simple equation to help you figure out your rate:

Initial rate = Upper coil x lower coil Upper coil + lower coilThis initial spring rate will be your spring rate until your coilover compresses enough for the coil slider to stop and the lower coil to become the only actively moving coil.

Choosing coils

When choosing coils, it's a good rule of thumb to stay around 100 pounds of difference in spring rates of your two coils (example: a 250 over 350). There is no law or rule against having more of a difference (in fact we run 200 pounds of difference on one of our trucks) and it can sometimes be a good thing if you are really running the truck hard and you want a really stiff second rate (once the slider stops moving) to slow down your truck's shock compression. But this, like high pressures of nitrogen in a shock, is a sort of Band Aid, and compression slowing should truly be done by valving of the shock.

Coil lengths should be the same as the stroke of the shock (14-inch stroke shocks get two 14-inch-long coils), but we have seen instances where (usually for clearance reasons during mounting) shorter coils are used on top with the coil retainer threaded further down on the shock. If you must do this, always make sure the lower coil is still full length so the coil slider is not able to fall off the shock's body and onto the shaft during full shock extension.

When choosing spring rates, you must first know the weight of your truck at each corner. A 250-pound spring rate will take 250 pounds to collapse that coil 1-inch. Your initial spring rate (see formula above) is up to you, and choosing softly or stiffly rated coils to have your coilovers ride the way you want is up to you as well. If you're going slow, then you can probably get away with a super soft rate. If you're going fast or jumping, you probably want a much stiffer rate to help slow down/absorb compression.

The specs can usually be found on the side of the coil like on the Eibach coil shown here. The three numbers stand for coil length, coil inner diameter, and spring rate (this coil shows 1600.250.0200: 1600 means 16 inches, 250 means a 2.5-inch inner diameter or shock body diameter, and 200 means a 200-pound spring rate).

When your vehicle is at rest, it's up to you how much shock shaft you want showing. If we might make a suggestion, 6 inches of shaft showing on a 12-inch-stroke shock is a good all-around player. This will give you a lot of extension for crawling around and drooping the suspension out, but will also leave you enough shaft to really compress it during a hard hit.

Check out Eibach's Web site (www.eibach.com) for more spring-rate formulas and information on setting up your own coilovers.

Warnings

Do not weld near the coilover shocks, allowing current to be conducted through them. This could lead to welding the shock together and it no longer compressing, in which case you're done. An arc through the shock can also cause the seals to leak as current jumps through it.

When setting up your coil package, be careful not to scratch the coils. Most shops will swap out your coils if they are in perfect condition and you find you have too stiff or too soft a coil rate.

Before you rebuild your coilover shock or send it somewhere to have it done, make sure it's worth it. You'd be surprised what wasted shocks can be rebuilt into, but sometimes the labor and parts can get close to the price of a complete shock, so make sure a new shock wouldn't make it easier for around the same price.