When it comes to trail rigs, the Jeep Wrangler Rubicon is about as good as it gets from the factory. And with the added wheelbase and cargo space available in the Unlimited version, you get a rig that can both climb better and carry more gear than any of its siblings. Not a bad place to start, if you ask us. That's why we decided to borrow a brand-new '06 LJ Rubicon and deck it out with all our favorite essentials in aftermarket suspension and drivetrain upgrades. Follow along as we take Jeep's best-to-date to new heights. Special thanks to the wrenches at Train's 4x4, who can transform just about any vehicle from showroom-stock to trail-boss in just a day's time.

For wheels, we picked a nice set of 17x9-inch aluminum Walker Evans bead locks for this project. These wheels are one of the best values, dollar for dollar, in the cast wheel department. Designed to survive the rigors of Baja racing, these wheels came in an attractive polished finish, with all the appropriate Grade 8 bead-lock ring hardware.

For traction, we chose the competition-proven 37x12.50/17 BFG Krawler. These tires are legendary among rock racers, and because our donor Jeep's owner was planning on towing his rig most of the time, we figured the Krawlers were a good match. The tires were mounted and balanced by California Automotive and Tire of Salinas, California. Additionally, the folks at Right Gear and Axle provided a Warn premium hub conversion kit and installed it for us at the same time they did the gears. This system is a must-have for anyone planning to do any serious trail work in a Dana 44-equipped TJ/LJ. We made this conversion to our own project Teal-J II (Oct. '05). The kit adds valuable girth to the OE stub axles as well as increasing the lifespan of all front drivetrain componentry. We also noticed a slight improvement in highway fuel economy with the kit installed while running stock tires and wheels.

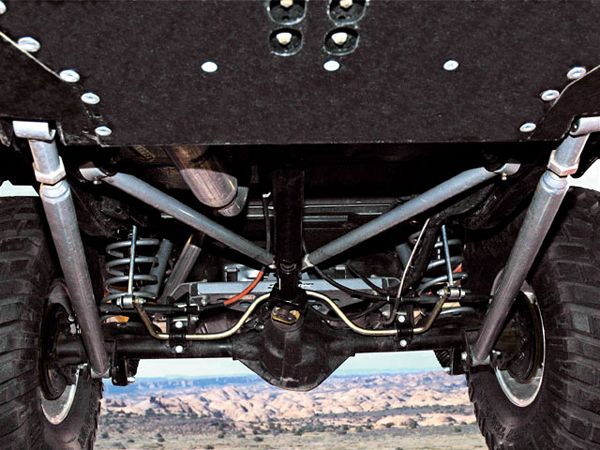

Just as we were going to press, Rubicon Express released a new tri-link option for the LJ long-arm system. This kit changes the rear upper control-arm mounting locations (and geometry) so as to allow removal of the rear-axle track bar. R.E. spent countless hours developing this upgrade to ensure proper handling characteristics in all driving scenarios. One of the advantages of tri-link rear suspension is increased freedom of movement that allows the axle to respond to the terrain better. This is an advantage when rockcrawling at low speeds and also at high speeds, such as when blasting up a desert sand wash. The disadvantage is an increased roll center, which gives an effect similar to a high center of gravity.

We had the opportunity to drive and wheel an LJ equipped with the Tri-Link system in Moab. We liked the way it worked on the trail better than the standard five-bar system. On the road, the Tri-Link was the best driving tri-link suspension system we've tested, though as previously mentioned the handling characteristics inherent with tri-link suspension systems contributed to more body roll than we felt comfortable with for an everyday driver. That's not to say we wouldn't drive it on the street, it's just not the kit we'd install on our teenage daughter's commuter Jeep. In closing, we found the Rubicon Express Tri-Link kit handled just as their marketing department said it would. The slight on-road handling disadvantages will be well worth the increased off-road performance for most customers.

Luckily for us, our donor Jeep made it out to Moab this year for the annual Easter Jeep Safari gathering. We're happy to say the suspension worked flawlessly, as did the drivetrain upgrades we installed. However, the two areas we failed to address in this build did in fact fail; steering and the rear ring-and-pinion. Our owner found out the hard way that even though he upgraded to a Teraflex crossover high-steer conversion shortly before Moab, the OE steering box was not at all willing to push around 37-inch rubber in the rocks, making quick work of the Jeep's OE sector shaft on Moab's Green Day trail. Luckily, Pat Gremillion of Premier Power Welder was there to lend a helping hand so we could continue our suspension testing. In the future, this particular Jeep will receive a ram-assist steering upgrade to help relieve the additional steering force.

Later in the week, on Golden Spike trail, our test mule broke a rear ring gear trying to climb a 3-foot ledge. Needless to say, cryogenically treating the ring-and-pinion is in the near future. Otherwise, piloting this Jeep on the trail was pretty much a point-and-shoot affair. On the road, the vehicle felt much smoother than stock, and the RTI scores with and without the addition of a Currie Anti-Rock sway bar were much more impressive (907 with the Anti-Rock connected).

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow