My wife had been complaining of this strange clunking noise coming from the front of our Grand Cherokee. Said she only heard it when she turned tight at low speeds. I looked: It was just the new tires rubbing against the control arms. No big thing-just don't turn so tight, I told her.

A week later, she said it was getting worse, so I looked again. I jacked up the front end and turned the tires fully to the left and then to the right and spun them, thinking that maybe an axle CV joint was going bad, or a wheel bearing. No noise. I grabbed the top of the tire and tried to shake it, but no movement. I had her turn the steering wheel slightly back and forth, just to take up any slack, and watched for any looseness in the tie-rod ends: None.

I did note that at full suspension drop and a full lock turn to the right, the tie rod made a slight contact with the sway-bar disconnect, but this wouldn't be causing the noise. I checked both of the lower shock mounts. These are some of JKS's aftermarket mounts, so that I could use the eye-type-bushing Rancho shocks instead of the stock stem-type. Everything was tight here. I checked the track bar: Nice and tight at both ends. The coil springs were firmly seated like they should be. I grabbed the driveshaft and gave it a hard shake. It didn't move-the double-cardan joint at the transfer case was still tight, and it seemed also tight at the CV joint for the pinion. The rubber boot covering it didn't show any damage.

I didn't deny her the fact that there was some kind of noise, just the fact that I couldn't duplicate it. A couple of weeks later, she headed to town, got a mile away, and came home saying something was drastically wrong, with the noise now constant. One look was all it took to tell me that the front driveshaft CV joint was at an odd angle.

Something was amiss here. When she pulled it into the shop, the CV joint would spin and then catch, and then spin again. Yep, something's definitely wrong here. OK, the Jeep had 80,000 miles on it with a 3-inch Teraflex lift kit. Guess it has the right to die. Now what?

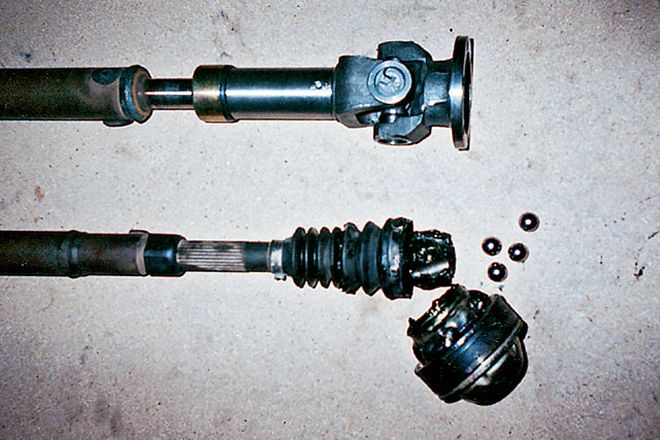

The local driveshaft shop says it's a dealer item. A check with the Jeep dealer: Not in stock, and the price made me sit down real quick. OK, now what again? How about building a new shaft and eliminating the front CV and replacing the pinion yoke with one that took a standard 1310-series U-joint? "Sure," the driveshaft shop guy said, with a big "maybe." Bring in the original pinion yoke, and maybe we can find a standard yoke with the right length, spline, and diameter to fit.

Now, the problem: My real Jeep was lacking insurance at the time, the truck was at the dealer having warranty work done, and 40 miles to town was a long way to walk, even if the local shop could make it up for me right away. It was Internet research time, and Rockford Driveline came to my rescue (815/962-1411, www.rockforddriveline.com). Seems they'd also run into this problem, so they made up a special conversion shaft. Best of all, they had one in stock and could ship it UPS that day. May I add that the fella I spoke to was a super-nice guy?

The Rockford conversion uses a Spicer double-cardan joint, like the original on the transfer case, and a Spicer 1310 series with a special flange on the slip yoke that bolts right up to the Cherokee's pinion flange. These are quality, heavy-duty parts with grease fittings, no less. Now, there is no binding of the joints at full drop, and no vibration at freeway speeds. The price was, like, half of what the Jeep dealer quoted me for a replacement. Beside that, my wife is happy that she has her Cherokee back, and with no noise.