Sean P. Holman

Contributor

Sean P. Holman

Contributor

(Editor's note: As time permits, we'll focus our attention in each issue of FW on a single transmission, transfer case, or axle that was popular in a variety of past OE truck and Jeep applications, and which still holds appeal to truck builders today. We'll examine their componentry, talk to experts about their strengths, look for any obvious weak links, and recommend strong fixes when applicable. This month, we delve inside the popular Dana 44 and Dana 60 axles and see how they have improved in the aftermarket for wheelers.

Dana 44 and Dana 60: two of the axles coveted by wheelers in their quest for more robust rigs. While the stock or "junkyard" axles are desirable in their own right, companies such as Dynatrac in Huntington Beach, California, have been building brand new replacement axles for the four-wheeling community for over 15 years.

Remember, the main job of an axle housing is to support the weight of vehicle, support the gears in mesh, and to maintain its shape under load. Stronger, performance-oriented axles are improved in these areas to offer better reliability and more confidence on the trail. We spent a day at Dynatrac to learn about the differences between the 44 and 60 to help you determine which axle might be right for you.

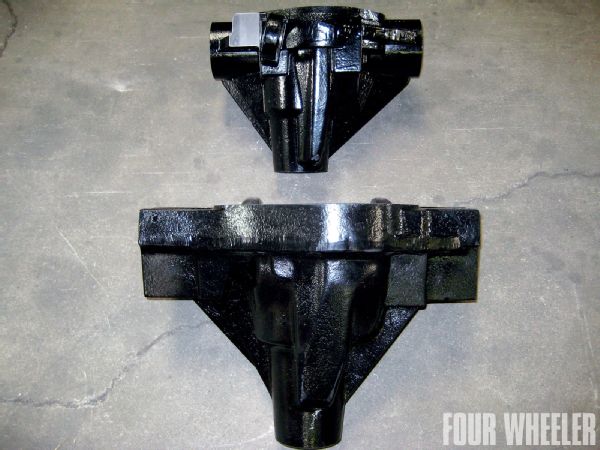

This is a stock Wrangler Rubicon JK Dana 44 next to a Dynatrac ProRock 44 housing. Note that the ProRock has larger 3-inch axle tube bores.

This is a stock Wrangler Rubicon JK Dana 44 next to a Dynatrac ProRock 44 housing. Note that the ProRock has larger 3-inch axle tube bores.

To better understand performance Dana axles, we'll first give you a brief history of the Dana 44 and Dana 60.

The Dana 44 was introduced after World War II and is commonly found under the front and rear of a wide variety of Jeeps, as well as International Harvester, Dodge, Studebaker and Ford trucks, and even under the rear of Isuzu Rodeos and Honda Passports up until the mid-'90s. It was offered in a centered or offset design, low or high pinion, and with either two-piece or flanged axleshafts.

Starting in 1972, modern factory Dana 44s had 30-spine axleshafts with a thickness of 1.31 inches (earlier axles were 10- or 19-spline), although the rear next-generation Dana 44 found on the 2007-present Jeep Wrangler JK has 32-spline shafts. Axletube diameters range from 2.5 inches to 3 inches, and semi-floating models have a gross axle weight rating (GAWR) of 3,500 pounds and an output torque rating of 3,460 lb-ft. Ring gear diameter is 8.5 inches, while next-generation axles go up to 8.8 inches. The available gear spreads for the Dana 44 range from 2.72:1 to 5.89:1, and both five- and six-lug versions were used in OE applications.

This is the JK 44 housing close up. Take a look at the bolt ring (arrow) and webbing (arrow).

This is the JK 44 housing close up. Take a look at the bolt ring (arrow) and webbing (arrow).

The Dana 60, a heavier-duty axle than the Dana 44, was first used in the 1950s. It was the axle of choice under countless Dodge, Ford, GM, Studebaker, IH and Jeep 3/4-ton and 1-ton fullsize trucks, as well as Ramchargers and Trail Dusters with the 440ci V-8, and some heavy-duty 1/2-ton Ford and IH trucks. The Dana 60 can even be found underneath some performance Chrysler cars of the late '60s and early '70s, and was a very rare option on early-'60s CJs. Late-model Dana 60s are typically equipped with 30-spline axleshafts, in either a semi- or full-floating configuration; 35-spline axleshafts are found in some applications from the factory, but are the standard upgrade in the aftermarket.

Axletubes vary in size from 3 inches to 3.5 inches in diameter, and Dana lists the GAWR as 5,500 lb-ft for a semi-floating axle, while the full-floaters are good for 6,000 to 6,500 pounds. Both versions have a torque output rating of 5,500 lb-ft. The Dana 60's ring gear is 9.75 inches in diameter, and the available gear spread ranges from 3.31:1 to 7.17:1. There are both low- and high-pinion designs, and six- and eight-lug wheel bolt patterns.

Of course, these brief descriptions are generalizations about the axles and don't cover every configuration that was made. Both the Dana 44 and Dana 60 enjoy enormous aftermarket support and can be equipped with just about any traction aid available in the market, whether it is a tried and trued Detroit Locker, selectable locker, or a helical- or clutch/cone-style limited slip.

Looking closely at the ProRock 44 housing, you can see the extra material in the bolt ring (arrow) and webbing (arrow). These are just a couple of the key features that give the Dynatrac product its enhanced strength and rigidity.

Looking closely at the ProRock 44 housing, you can see the extra material in the bolt ring (arrow) and webbing (arrow). These are just a couple of the key features that give the Dynatrac product its enhanced strength and rigidity.

So, what makes a performance axle better than a stock axle? Let's look at a rear Dynatrac 60 versus a rear junkyard Dana 60. For starters, the Dynatrac 60 comes standard with larger diameter 35-spline axleshafts (1.5 inches) of a higher material quality, compared to the typical stock 3/4-ton Dana 60 with 30-spline axle shafts. The Dynatrac 60 also has Dana 70-size spindles, thicker tubes, higher-strength and higher-quality material, and stronger castings. And while the majority of stock Dana 60 axles have drum brakes, Dynatrac outfits its 60s with standard disc brakes. Lastly, the Dynatrac housing is much more robust than any stock unit and in many areas has been subtly enhanced for stoutness.

Part of Dynatrac's success comes from its proficiency at application engineering, and engineering aptitude in general. Dynatrac doesn't just add material and call it stronger; they strategically build strength and rigidity into the product and then prove it through testing.

The ProRock 44 (foreground) and the ProRock 60 (background) are instantly recognizable by their unique shapes that offer unmatched ground clearance.

The ProRock 44 (foreground) and the ProRock 60 (background) are instantly recognizable by their unique shapes that offer unmatched ground clearance.

Another area to consider is the material that goes into making the product. Just because two housings or axle shafts look the same and are said to have the same grade of metal, it does not make them equal. Dynatrac products are developed and manufactured in the United States with superior American steel. Because of the level of American manufacturing sophistication and quality control, Dynatrac consistently delivers on its promise of quality and strength. And if there is breakage, Dynatrac offers a "No Fault" 12-month, unlimited mileage warranty. Dynatrac makes no apologies for not offering the lowest priced products. Because of the value built into every axle, coupled with the engineering effort and premium materials, you certainly get what you pay for.

Dynatrac may be known for its 60s, but they have also made a name for themselves with their 44 axles. In fact, Dynatrac offers a complete family of axles-all the way up to the Pro Series 80 for extreme needs. And while Dynatrac has many application-specific configurations that come complete with stronger-than-stock bracketry and are ready to bolt on, they do custom applications for any of their axles and the customer always has the choice of front or rear placement, bolt pattern, gear ratio, traction aide, and axleshafts.

So how do you decide which axle is right for you? Dynatrac looks at four criteria when recommending an axle for their customers: 1. Gross vehicle weight; 2. Tire Diameter; 3. Intended use; and 4. Transfer case ratio. With those questions answered, you will be well on your way to experiencing more worry-free and challenging adventures in your trail rig of choice.

In this photo, the size difference between a ProRock 44 and ProRock 60 are obvious.

In this photo, the size difference between a ProRock 44 and ProRock 60 are obvious.

While visiting the Dynatrac facility, we snapped a few photos to give you an up-close look at these popular axles.

Cost vs. Strength

Depending on driving style, it is generally accepted that a properly built Dana 44 is strong enough to handle a 37-inch tire. And since 37s seem to be the standard "go-big" tire size these days, we wanted to directly compare a rear Dana 44 to a Dana 60 on a fictional TJ with 37-inch tires (that is otherwise stock) and see where we came out. Both axles would be rear configurations, purchased from Dynatrac, set up with the same gear ratio, and both would have lockers.

What you get with the Mopar Jeep Wrangler JK-to-TJ next-generation Dana 44 is a much stronger 44 than what originally came on the TJ. The Mopar 44 offers lower weight than a 60 and bigger discs than a stock TJ Dana 44. Other benefits are 32-spline shafts and a very palatable price point of just $3,995.

The front ProRock 44 end forgings (right) are also more robust than the factory front JK 44 forgings (left).

The front ProRock 44 end forgings (right) are also more robust than the factory front JK 44 forgings (left).

With 35-spline shafts, a bigger ring and pinion, and a stronger housing and tubes, the ProRock 60 would most likely be more axle than this TJ would ever need, giving the owner some reserve strength for those hardcore outings. The ProRock 60 also offers more ground clearance than a Dana 44 and adds some bragging rights on the trail. Depending on the locker, the ProRock 60 would come in around $5,600 to $5,900.

Both have their benefits, but it all comes down to what you can afford, and there is no wrong answer here. This TJ owner, with no more than a 4.0:1 transfer case and a stock engine, would probably have no issues with the Mopar 44. However, if there were plans to do deeper transfer-case gearing or an engine swap down the line, there is no question we'd save up a little longer and go with the ProRock 60.

Mopar JK to ProRock 60 TJ Dana 44 Lower Weight X Overall Strength X Ground Clearance X 35-spline axle shafts X Lower Price X PhotosView Slideshow