Jerrod Jones

Former Editor, Off Road

Jerrod Jones

Former Editor, Off Road

Are you running stock axles under your Wrangler? If so, how many degrees of negative camber does your frontend have? We know those front tires have a tilt to them if you do any off-roading. And while camber can be a good thing in an IFS streetcar, it usually means faster tire wear, ruined ball joints, and leaky seals in a solid-axle 4x4, all due to a bent axlehousing. Lesson learned: The stock axletubes and inner Cs under ’07-’15 Wranglers are inadequate when used off-road. Now, what are you going to do about it? You’re looking at $1,000 at least for a stock replacement housing, not to mention the labor to swap parts over—if other parts aren’t damaged. A complete replacement axle will run you $2,500 or more. Add some cost if it’s a Rubicon Dana 44 axle you’re trying to replace. And even if you replace the stock housing, it’s still just as likely to bend again unless you add metal to it. Therefore, you could truss the axle, brace the inner Cs, sleeve the axletubes, and spend a lot of money trying to keep a weak axle from bending.

Your money would be better spent investing into a hardcore replacement housing. Think 3-inch axletubes with a 5⁄16-inch wall thickness; inner Cs so thick that they make those of some Dana 60s look small. And why not have a centersection built for pounding on rocks? That’s where G2 Axle & Gear comes in. After lots of testing and metal thickness combinations, G2 has released its new CORE 44 axle line for JK Wranglers. The new CORE 44 housings are built to take abuse and stock JK outers. You’ll still have your factory sensors and brakes working with the vehicle’s stability and ABS systems, but you’ll be rid of any potential weakness found within stock JK axles. And one of the best parts could be the price: For $2,000, you can get a replacement CORE 44 housing and swap all existing Rubicon 44 gear into it. It will come with all the correctly positioned brackets, mounts, and a huge jump in robustness. If you want to add even more strength (or are a Dana 30 JK owner), you can order a loaded CORE 44 axle with your choice of 30, 32, or 35-spline axleshafts and differentials.

When we decided to re-axle our JK Wrangler project, there was no question: We were getting the packed CORE 44s with American-made chromoly 35-spline axleshafts and ARB Air Lockers. Not only would we be getting Dana 60 strength throughout a lot of the axle, but we’d have completely bolt-in units that would be a breeze to install under our Jeep JK Wrangler. We know they’ll work with the factory sensors, and we won’t have any funky check engine or brake warning lights blaring on the instrument cluster.

Now, if only Jeep would just make CORE 44s an option on the build sheet when you buy a new Wrangler.

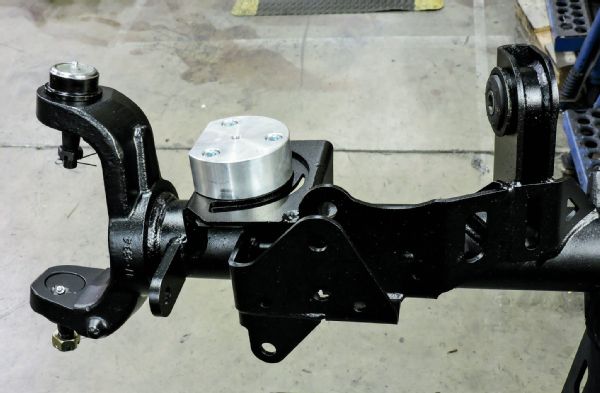

All brackets on the CORE 44 housings are made from laser-cut 1⁄4-inch steel. They’re welded onto 3-inch-diameter axletubes with a 5⁄16-inch wall thickness, which allows the housing to flex slightly while preventing bending. The company experimented with 1⁄2-inch axletubes but found them to be too ridged, plus the 5⁄16-inch tubes give more room for 11⁄2-inch, 35-spline axleshafts. Cast bump pads are bolted onto a 1⁄4-inch steel spring mount base that is welded onto the axle. All welding and assembly of the axlehousings is done in California. The forged inner Cs accommodate stock JK Wrangler knuckles, but are much thicker (about twice the thickness) to prevent bending. They hold new ball joints with a metal-on-metal design for increased strength and diminished ball joint wear.

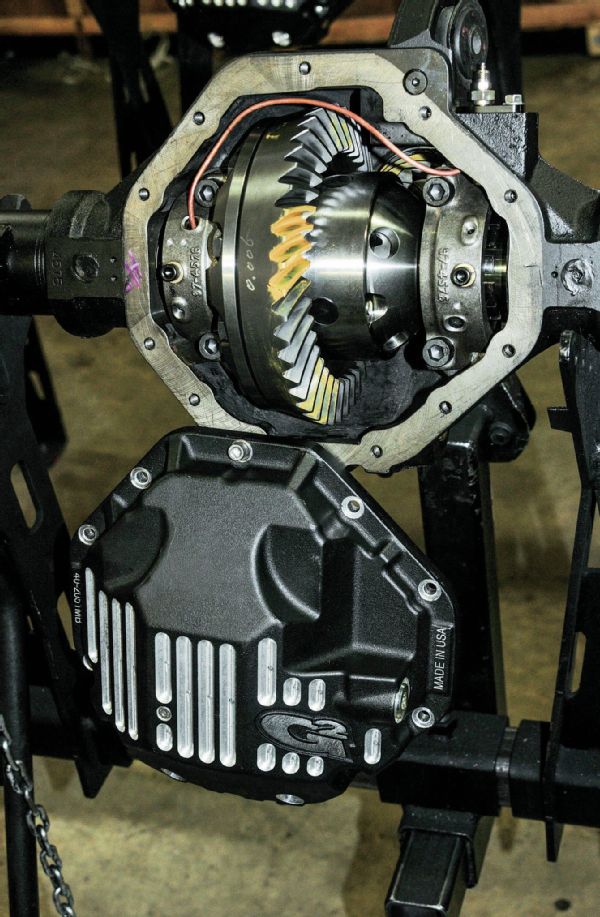

CORE 44 axlehousings use an 8.9-inch ring gear—the same size as a stock JK Rubicon—so you can swap your Rubicon parts easily into G2’s new housing. While the 8.9-inch ring gear is a bit smaller than a Dana 60’s ring gear, the pinion gear’s shaft diameters are the same. Assuming you order a loaded axle, you’ll get a choice of 4.56, 4.88, 5.13, or 5.38 G2 gears. Each G2 ring-and-pinion is pre-run to ensure a proper mesh pattern evident on the teeth. Our assembly tech, Noah Korman, tells us he matches that pattern when he sets up the ring-and-pinion. For these particular axles, we’ve chosen a 5.13:1 ratio.

Besides an all-around stronger housing and centersection, what sets these housings mechanically apart is the unique G-Lock spanner adjuster nut system. Instead of using shims, the installer uses these spanner nuts to easily adjust and set backlash and bearing preload.

We chose to install a pair of ARB Air Lockers designed for 35-spline axleshafts into our front and rear CORE 44s. As good as the old ARBs were, the new units are a two-piece design (old ones were a three-piece) and now come with a full five-year warranty compared with the two-year warranty of the old units. In the off chance we ever have a problem with these burly traction devices, ARB has our back.

PhotosView SlideshowG2’s CORE 44 axles feature forged bearing caps that work in conjunction with the spanner nuts. The setup uses metric bearings (same as a JK Rubicon) so the stock Rubicon locker can be reused. The caps also are machined with a hole for running an ARB air line through and a threaded hole for an Allen set screw. Indents on the spanner nuts are lined up with the set screw hole, and the set screw holds the spanner nut in place.

Both front and rear CORE 44 housings are machined to accommodate the wiring (or hoses) of stock Rubicon locking differentials and other selectable lockers and different plugs are available depending on whether you’re running an ARB, factory Rubicon locker, or mechanical locker. The ARB air line is carefully run up and over the ring gear and through the ARB fitting that G2 has made to fit the CORE 44 housings. On the ring gear, you can see the pattern in the gear marking compound has lined up with the initial marks set in during the gear pre-run.

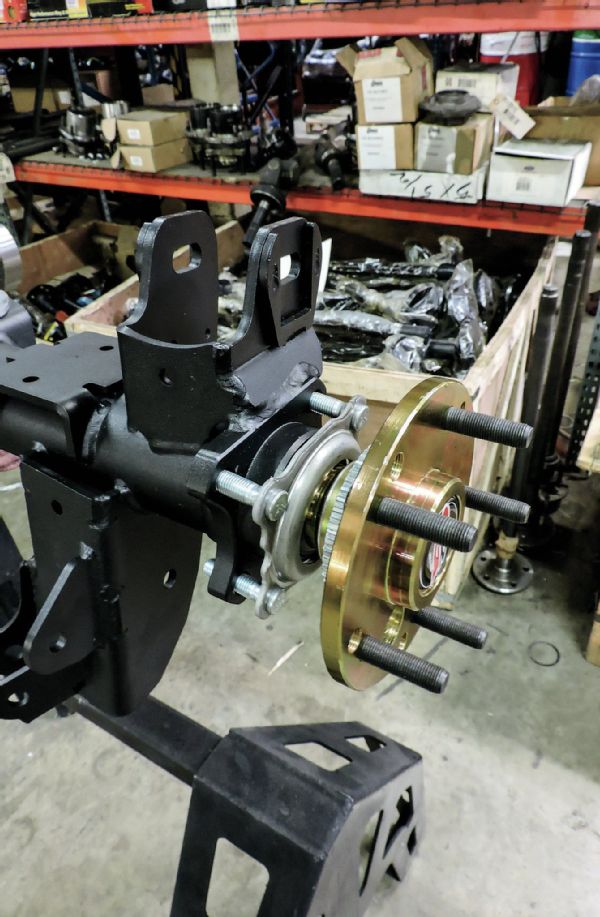

Upgrading to the premium 35-spline package gets you USA-made 4340 chromoly, 35-spline G2 Placer Gold axleshafts with Spicer 5-7166X U-joints. We can’t say enough good things about these induction-hardened, rolled-spline shafts. For a U-jointed axleshaft, they’re about as good as it gets!

Before the axles are ready to ship, every selectable locker is checked to make sure it correctly actuates and locks the axleshafts together. Once the Core 44 diff cover was bolted on, our front axle was finished. The CORE 44 axles reuse factory Wrangler knuckles, brakes, and steering linkage. The brackets fix a lot of problems you’ll encounter with a lifted JK, but we’ll cover all that in a separate story when we install these units in our JK project vehicle.

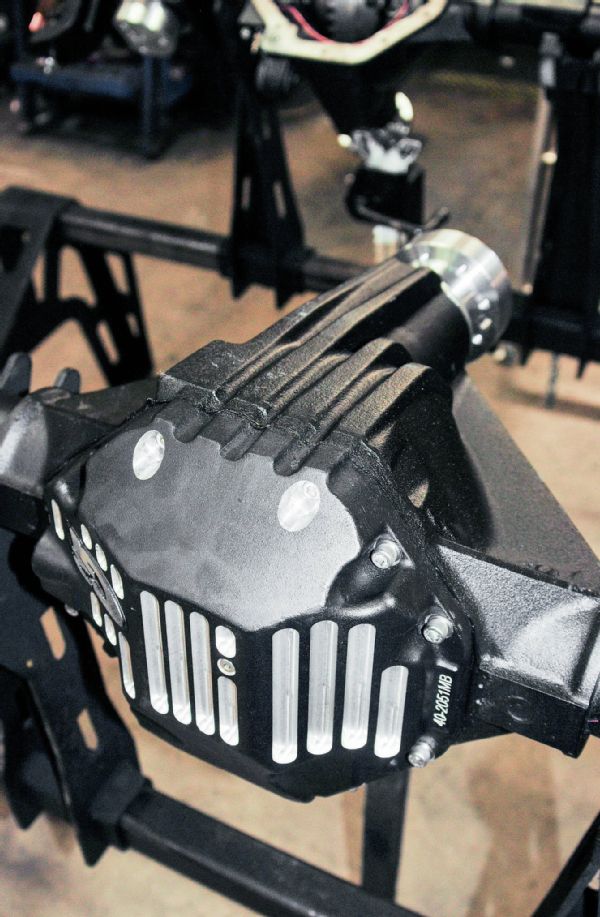

Here’s the completed front CORE 44, properly packed with an ARB locker into a unique centersection that is reinforced for improved strength and less gear deflection. It uses a specific 356 aluminum differential cover heat treated to a T6 hardness, designed specifically for the CORE 44 centersection. At the bottom point of potential rock impact, the diff cover is 1⁄2-inch thick. We’ve hung the diff cover by one bolt off the bottom of the centersection purely for illustration purposes.

Much like the front CORE 44 axle, the rear axle is completely built and assembled in California, using 1⁄4-inch steel brackets, billet spring pads on the coil mounts, and a unique centersection. Our rear axle was built with 35-spline G2 Placer Gold axleshafts and ARB Air Locker to match the front.

While the rear CORE 44 does come with factory JK suspension mounts welded onto the axle, you’ll note six threaded holes on the top of the rear centersection. This gives an excellent mount for an aftermarket triangulated four-link, should an owner decide to go that route.

The bottom of both the front and rear centersections have external ribbing that adds strength to the housing and acts as a skidplate to protect from potential rock damage.

Just as in the front, the rear CORE 44 axle reuses the factory brakes and sensors.

The New ARB JK Locker

Can you believe the ARB Air Locker is celebrating its 25th birthday? And as such, it’s received an overhaul, not only to its design, but also to its warranty. The new 35-spline ARB locker has a two-piece design (instead of a three-piece) and five-year warranty that covers everything from the forged side gears to the uniquely designed pinion gears.

C the Difference?

Core 44 inner C compared to a stock-sized inner C. What else needs to be said about the size difference of the new forged inner Cs?