Ken Brubaker

Senior Editor, Four Wheeler

Ken Brubaker

Senior Editor, Four Wheeler

There wasn't any particular thump, grind, or clunk that triggered our desire to rebuild the rear 10 1/2-inch axle in our "Workin' Dog" '99 Power Stroke-powered Ford Super Duty. Instead, it was the 210,000 miles on the truck's odometer that made us nervous. The truck is in use almost constantly for business, so if the rear axle failed, the result would be unplanned downtime, which is not a good thing.

We turned to the Naeger brothers at Custom Differentials in Bloomsdale, Missouri. Jeremy, a former Top Truck Challenge champion, and his brother Patrick are axle gurus with 37 years of combined axle experience. Custom Differentials specializes in everything from basic rebuilds to the most extreme custom builds. They can either remove and repair your axle in their fully equipped shop, or you can remove the axle yourself (like we did) and bring it to them for service.

When it came to parts, we contacted the folks at Drivetrain Warehouse. They've been around since 1962 and their product portfolio is incredible. They carry installation kits, gearsets, general replacement parts, limited-slip and locking differentials, hubs, axleshafts, gaskets, and so on, from a number of manufacturers. The beauty of this is that with one call you can get everything needed to rebuild or upgrade an axle.

How did the rebuild go? What did we find in our high-mileage axle? What tricks did we learn from Custom Differentials? Read on.

When it comes to axle work, there's no substitute for a good shop staffed by knowledgeable technicians, which is why we chose to have the team at Custom Differentials rebuild our axle.

When it comes to axle work, there's no substitute for a good shop staffed by knowledgeable technicians, which is why we chose to have the team at Custom Differentials rebuild our axle.

About The Ford 10 1/2-inch

The 10 1/2-inch (commonly referred to as the "Sterling 10 1/2") is a full-float axle with disc brakes found in 1999-2010 Ford Super Duty F-250 and Super Duty F-350 trucks. It weighs in at approximately 333 pounds in single rear-wheel versions. The ring gear diameter and pinion shaft length are both 10 1/2 inches. It has a pinion shaft spline count of 31 and an axleshaft spline count of 35. Compared to its predecessors, the first- and second-generation 10 1/4-inch axles, the 10 1/2-inch axle obviously has a larger ring gear, which improved its overall strength and addressed the premature failure issues of the of the 10 1/4-inch axles when used with 4.10:1 or numerically higher gear ratios. There are a number of limited-slip and locker options available, and there are even aftermarket axleshafts available.

Bottom Line

We now have the peace of mind knowing that unless we do something stupid, our axle will provide years of trouble-free service. Best of all, we chose the downtime for our truck. We hate surprises, and sitting on the side of the road with a blown axle isn't good for the blood pressure or the wallet. Since the rebuild, we've been piling the miles on our truck, and the Traction-Lok has exceeded our expectations. It has provided the added traction our Power Stroke-powered rig dearly needed, and its operation is seamless and chatter-free. We're also digging the beefiness of the Genuine Gear G2 diff cover; it has contributed to cooler diff temperatures.

Custom Diff has the equipment to move heavy axles, so it was easy to get the unit out of the bed of our project Power Wagon and into the work area after the seven-hour trip from the Four Wheeler Midwest Bureau. Once on the stand, the first thing Patrick Naeger did was remove the cover and start disassembling the axle. Once the axle was apart, he steam cleaned the housing.

Custom Diff has the equipment to move heavy axles, so it was easy to get the unit out of the bed of our project Power Wagon and into the work area after the seven-hour trip from the Four Wheeler Midwest Bureau. Once on the stand, the first thing Patrick Naeger did was remove the cover and start disassembling the axle. Once the axle was apart, he steam cleaned the housing.

With the axle apart and on the bench, we could see that our bearings and races didn't have much life left. They were all heavily worn, and massive failure was not far away. When the bearings are worn, typically this means the carrier is loose, which puts a side-load on the axle gear hub. This causes the bore that the axle gear fits into to become loose. Translation: The carrier is shot. This wear is typical for a high-mileage axle.

With the axle apart and on the bench, we could see that our bearings and races didn't have much life left. They were all heavily worn, and massive failure was not far away. When the bearings are worn, typically this means the carrier is loose, which puts a side-load on the axle gear hub. This causes the bore that the axle gear fits into to become loose. Translation: The carrier is shot. This wear is typical for a high-mileage axle.

Here's a photo of one of our heavily pitted bearing races.

Here's a photo of one of our heavily pitted bearing races.

Typically, you want to replace everything when doing a rebuild. We used a Genuine Gear bearing kit and an AAM gearset, and we also upgraded to a beefy Genuine Gear G2 aluminum diff cover. The Ford Traction-Lok limited-slip differential was from Custom Differentials.

Typically, you want to replace everything when doing a rebuild. We used a Genuine Gear bearing kit and an AAM gearset, and we also upgraded to a beefy Genuine Gear G2 aluminum diff cover. The Ford Traction-Lok limited-slip differential was from Custom Differentials.

There's more to the disassembly of an axle than you may think. For instance, the bearing caps must be marked so they can be reinstalled in exactly the same position. In addition, careful attention has to be paid to what thickness shims were used from the factory. Most of the time, using the same thickness of shims will get you in the ballpark for reassembly. Here, the old pinion bearing is removed from the pinion shaft so the shim can be removed and measured.

There's more to the disassembly of an axle than you may think. For instance, the bearing caps must be marked so they can be reinstalled in exactly the same position. In addition, careful attention has to be paid to what thickness shims were used from the factory. Most of the time, using the same thickness of shims will get you in the ballpark for reassembly. Here, the old pinion bearing is removed from the pinion shaft so the shim can be removed and measured.

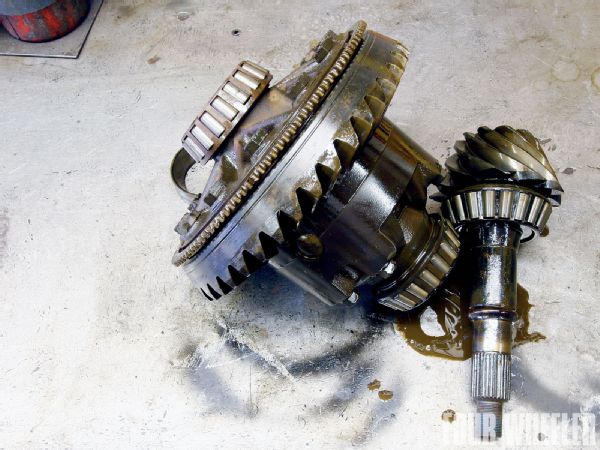

Here you can see the old factory differential assembly next to our new Ford Traction-Lok limited-slip. We wanted to improve traction and the Ford unit is an often overlooked option. It does have wear items like the clutch material and a spring washer, but it's a three-spider, heavy-duty unit that has a reputation of being very tough.

Here you can see the old factory differential assembly next to our new Ford Traction-Lok limited-slip. We wanted to improve traction and the Ford unit is an often overlooked option. It does have wear items like the clutch material and a spring washer, but it's a three-spider, heavy-duty unit that has a reputation of being very tough.

Custom Diff knows a number of tweaks that help make the Ford 10 1/2-inch more reliable. One is to use shouldered ring-gear bolts from Dana 60 or 70 applications, because they're less likely to loosen over time like the non-shouldered factory bolts. If the bolts loosen, major damage ensues. We also installed a new ABS ring, though our factory ring was fine and could've been reused.

Custom Diff knows a number of tweaks that help make the Ford 10 1/2-inch more reliable. One is to use shouldered ring-gear bolts from Dana 60 or 70 applications, because they're less likely to loosen over time like the non-shouldered factory bolts. If the bolts loosen, major damage ensues. We also installed a new ABS ring, though our factory ring was fine and could've been reused.

A 40-ton press was used to press on all of the carrier bearings and the pinion bearing. The primary concern here is to make sure the bearings are pressed all the way onto the carrier and pinion.

A 40-ton press was used to press on all of the carrier bearings and the pinion bearing. The primary concern here is to make sure the bearings are pressed all the way onto the carrier and pinion.

To enhance longevity, Custom Diff uses the taller pinion bearing and race out of the second-generation 10 1/4-inch Ford axle. Here you can see the taller bearing and race (pictured on the right) compared to the bearing and race found in the 10 1/2-inch axle (on the left).

To enhance longevity, Custom Diff uses the taller pinion bearing and race out of the second-generation 10 1/4-inch Ford axle. Here you can see the taller bearing and race (pictured on the right) compared to the bearing and race found in the 10 1/2-inch axle (on the left).

The new pinion races are tapped in until they seat completely. Then the pinion is installed and the preload set.

The new pinion races are tapped in until they seat completely. Then the pinion is installed and the preload set.

The axle comes from the factory with cast steel carrier bearing shims. The install kit uses stamped steel shims. Custom Diff prefers to use machined steel shims that are stronger and lock together. This simplifies installation and improves longevity.

The axle comes from the factory with cast steel carrier bearing shims. The install kit uses stamped steel shims. Custom Diff prefers to use machined steel shims that are stronger and lock together. This simplifies installation and improves longevity.

With the carrier reinstalled with the same carrier bearing shim thickness as stock, the bearing caps are tightened and the gear pattern is checked. Our pattern was actually very close, so only a slight change to shim thickness was required. Once the pattern was set, the new pinion seal and the factory yoke was installed.

With the carrier reinstalled with the same carrier bearing shim thickness as stock, the bearing caps are tightened and the gear pattern is checked. Our pattern was actually very close, so only a slight change to shim thickness was required. Once the pattern was set, the new pinion seal and the factory yoke was installed.

The ABS sensor simply reinstalls in its mount. As long as there's nothing wrong with it, there's no reason to replace it.

The ABS sensor simply reinstalls in its mount. As long as there's nothing wrong with it, there's no reason to replace it.

We ditched the factory diff cover in favor of a Genuine Gear G2 cover. This cover is cast from proprietary lightweight aluminum alloy to dissipate heat, it has reinforcing ribs for added rigidity and strength, is heat-treated and shot-peened to handle direct impact, and it has a fully machined seal surface for leak-free installation

We ditched the factory diff cover in favor of a Genuine Gear G2 cover. This cover is cast from proprietary lightweight aluminum alloy to dissipate heat, it has reinforcing ribs for added rigidity and strength, is heat-treated and shot-peened to handle direct impact, and it has a fully machined seal surface for leak-free installation

Black RTV silicone adhesive sealant was used to between the G2 diff cover and the axle housing, and then the cover was installed.

Black RTV silicone adhesive sealant was used to between the G2 diff cover and the axle housing, and then the cover was installed.

Custom Diff inspected our outer wheel bearings and found that they didn't have any play; they felt smooth and the inner oil-bath seals weren't leaking. If there was a problem, Custom Diff has the experience required to remove and replace the bearings and/or inner seals.

Custom Diff inspected our outer wheel bearings and found that they didn't have any play; they felt smooth and the inner oil-bath seals weren't leaking. If there was a problem, Custom Diff has the experience required to remove and replace the bearings and/or inner seals.

The last step was to reinstall the axles. These 10 1/2-inch axles are unique in that they use an O-ring on each axleshaft. This design is less likely to leak when compared to standard gaskets. Our axleshafts and O-rings were fine, so Custom Diff removed the O-rings, cleaned up the mounting surfaces, and then reinstalled the O-rings. It's also important to note that like the ring gear bolts, the axle mounting bolts are a non-shouldered design, and they can loosen over time. A good upgrade is to install shouldered bolts.

The last step was to reinstall the axles. These 10 1/2-inch axles are unique in that they use an O-ring on each axleshaft. This design is less likely to leak when compared to standard gaskets. Our axleshafts and O-rings were fine, so Custom Diff removed the O-rings, cleaned up the mounting surfaces, and then reinstalled the O-rings. It's also important to note that like the ring gear bolts, the axle mounting bolts are a non-shouldered design, and they can loosen over time. A good upgrade is to install shouldered bolts.

With that, our freshly rebuilt 10 1/2 was loaded into our project Power Wagon for the trip back to the Midwest Bureau.

With that, our freshly rebuilt 10 1/2 was loaded into our project Power Wagon for the trip back to the Midwest Bureau.

The Ford Traction-Lok requires that a friction modifier be added to the gear oil to eliminate clutch chatter.

The Ford Traction-Lok requires that a friction modifier be added to the gear oil to eliminate clutch chatter.

After adding the gear oil and friction modifier, Custom Diff recommends that the axle be tilted in each direction for about 20 minutes. This ensures that the wheel bearings are adequately lubed. When it comes to axle break-in, heat is the enemy. For this reason, Custom Diff recommends five short trips of up to 10 miles with hour-long cooling breaks between each run. After that, they recommend keeping trips under 50 miles for the first 500 miles.

After adding the gear oil and friction modifier, Custom Diff recommends that the axle be tilted in each direction for about 20 minutes. This ensures that the wheel bearings are adequately lubed. When it comes to axle break-in, heat is the enemy. For this reason, Custom Diff recommends five short trips of up to 10 miles with hour-long cooling breaks between each run. After that, they recommend keeping trips under 50 miles for the first 500 miles.