Today the big ticket item that separates the men from the boys on the trail is 1-ton axles. For those with the desire and the money, the dream of a bulletproof drivetrain is as easy as a phone call to any one of the many companies that specialize in custom differentials. For the rest of us, however, options are fewer. Wrecking yards typically have someone lined up to purchase all 1-ton axles that come in through the front gate. Usually these axles end up for sale online at a slightly higher price than you want to pay. Then there is the strategy of buying an old broken down 1-ton pickup, pulling the axles out and scrapping the body. Either way you have a situation where you have to tear apart the old axles and rebuild them with parts supplied from the aftermarket. Significant savings can be achieved going this route. However you have to have the storage space, tools, and time it takes to complete the project. Where a custom-built Dana 60 axle from a leading axle builder could cost upward of 5,000 bucks, a wrecking-yard Dana 60 might ring in at half as much.

Up front we started with a bare Dana 60 housing found under GM 1-ton pickups from '77 to '90. From there we added a set of Yukon 5:13:1 gears, chromoly axles and a pair of Randy's chromoly Super Joints. The differential we used was the now-discontinued TeraFlex T-locker. The master install kit from Randy's included all the bearings, seals, and hardware to properly install the gears inside the Dana 60 front housing. Altogether these parts cost $1,535.

Up front we started with a bare Dana 60 housing found under GM 1-ton pickups from '77 to '90. From there we added a set of Yukon 5:13:1 gears, chromoly axles and a pair of Randy's chromoly Super Joints. The differential we used was the now-discontinued TeraFlex T-locker. The master install kit from Randy's included all the bearings, seals, and hardware to properly install the gears inside the Dana 60 front housing. Altogether these parts cost $1,535.

If that still seems a little on the pricey side, consider this: hundreds of old '70s and '80s era 1-ton pickup trucks are out there rusting away in places most people never think to look-for instance, the back lot of the local school district or public services storage yard. That's where Dustin Chernoah of Ukiah, California, found his first prized Dana 60 front end. The '79 Chevy 3500 was long forgotten by school district officials and collecting cobwebs. We'd bet it would have remained that way for a very long time had Dustin not stopped by to offer the yard supervisor 500 bucks to haul it away. The deals are out there, you just have to look for them. Follow along now as we show off two relatively inexpensive routes to manhood for your 4x4.

The Total Cost Front Dana 60 $2,620 Rear Dana 70 $3,308

Notice the way the full-width axles make the BFG M/T tires stick out, leaving little reason to even have wheelwells. This wide stance is of great use on most trails, however, on the street many if not all states require mud flaps to prevent rocks from becoming projectiles. Part of Dustin's plan includes fabricating removable mud flaps that will keep the highway patrol at bay. Keep in mind that some organized trail rides don't allow vehicles over a certain track width, so if you're going to run full-width axles, understand that some sacrifices may be involved.

Notice the way the full-width axles make the BFG M/T tires stick out, leaving little reason to even have wheelwells. This wide stance is of great use on most trails, however, on the street many if not all states require mud flaps to prevent rocks from becoming projectiles. Part of Dustin's plan includes fabricating removable mud flaps that will keep the highway patrol at bay. Keep in mind that some organized trail rides don't allow vehicles over a certain track width, so if you're going to run full-width axles, understand that some sacrifices may be involved.

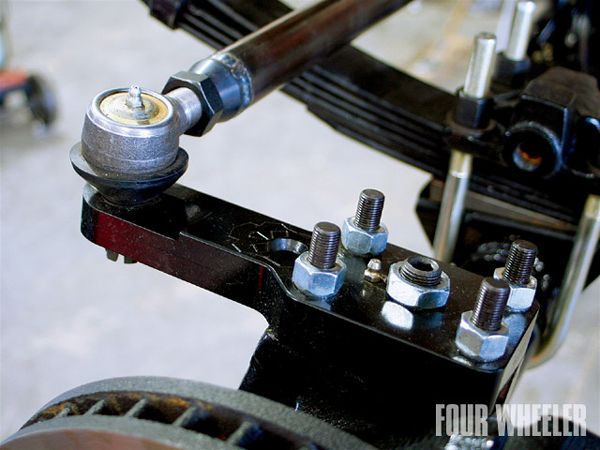

1. We scored a set of high-steer arms from Ballistic Fabrication of Tucson, Arizona. These arms are CNC-machined and feature 10-degree tie-rod end angle correction to lengthen the life of the joints. A set-screw design eliminates the need for the kingpin spring, and each kit includes two arms, eight studs and nuts, and all associated hardware. These arms are a bargain for $249 (at the time of print).

1. We scored a set of high-steer arms from Ballistic Fabrication of Tucson, Arizona. These arms are CNC-machined and feature 10-degree tie-rod end angle correction to lengthen the life of the joints. A set-screw design eliminates the need for the kingpin spring, and each kit includes two arms, eight studs and nuts, and all associated hardware. These arms are a bargain for $249 (at the time of print).

2. Dustin opted to reuse the front brake calipers and simply order new rotors and Warn lock-out hubs. Altogether these parts cost $304.

2. Dustin opted to reuse the front brake calipers and simply order new rotors and Warn lock-out hubs. Altogether these parts cost $304.

3. Due to the fact that the Chevy pickup spring pads were not intended for a lifted vehicle, Dustin had to install 6-degree shims to get the pinion pointed in the right direction. They cost $32 from Rubicon Express.

3. Due to the fact that the Chevy pickup spring pads were not intended for a lifted vehicle, Dustin had to install 6-degree shims to get the pinion pointed in the right direction. They cost $32 from Rubicon Express.

4. This is the finished product. Altogether this axle cost Dustin roughly $2,620 without tax or the TeraFlex T-locker differential, which you can't get anymore. Not bad considering a custom-built unit equivalent in strength would run easily twice that price.

4. This is the finished product. Altogether this axle cost Dustin roughly $2,620 without tax or the TeraFlex T-locker differential, which you can't get anymore. Not bad considering a custom-built unit equivalent in strength would run easily twice that price.

5. Moving to the rear axle, Dustin found a Dana 70U out of an '01 Dodge Ram 2500 at a local wrecking yard for $1,400. The reason he went with this particular rear axle is because it features disc brakes. To start this buildup, Dustin ordered a Detroit Locker for the earlier style Dana 70 HD. Next he got a set of 5.13:1 gears and a master install kit from Yukon Gear. The axleshafts are 35-splined units, also from Randy's Ring & Pinion, designed as a one-size-fits-all application for Dana 60s. Altogether these parts totaled $1,468 without tax.

5. Moving to the rear axle, Dustin found a Dana 70U out of an '01 Dodge Ram 2500 at a local wrecking yard for $1,400. The reason he went with this particular rear axle is because it features disc brakes. To start this buildup, Dustin ordered a Detroit Locker for the earlier style Dana 70 HD. Next he got a set of 5.13:1 gears and a master install kit from Yukon Gear. The axleshafts are 35-splined units, also from Randy's Ring & Pinion, designed as a one-size-fits-all application for Dana 60s. Altogether these parts totaled $1,468 without tax.

6. The Dana 70U rear disc brakes are massive compared to the original Jeep AMC 20 rear drum setup. As large as these brakes are, a brand-new fully loaded caliper costs only $170 each (with pads), or $240 for a pair at most any auto parts store. Dustin went ahead and ordered the new calipers because the factory units were in poor condition.

6. The Dana 70U rear disc brakes are massive compared to the original Jeep AMC 20 rear drum setup. As large as these brakes are, a brand-new fully loaded caliper costs only $170 each (with pads), or $240 for a pair at most any auto parts store. Dustin went ahead and ordered the new calipers because the factory units were in poor condition.

7. We thought it was worth mentioning that the Yukon axles are the one-size-fits-all type and require trimming prior to installation.

7. We thought it was worth mentioning that the Yukon axles are the one-size-fits-all type and require trimming prior to installation.

8. Due to the hardness of these shafts, we couldn't cut them with a portable bandsaw. Instead it required a circular chopsaw with a bi-metal blade.

8. Due to the hardness of these shafts, we couldn't cut them with a portable bandsaw. Instead it required a circular chopsaw with a bi-metal blade.

9. Here you can see the wear pattern Dustin ended up with after completing the gear installation.

9. Here you can see the wear pattern Dustin ended up with after completing the gear installation.

10. The tedious part of setting up a brand-new locker in a Dana 70 rear differential is setting the proper shim spacing on either side of the main bearings. The process requires that you install and remove the bearings by pressing several times until the proper shim spacing is attained.

10. The tedious part of setting up a brand-new locker in a Dana 70 rear differential is setting the proper shim spacing on either side of the main bearings. The process requires that you install and remove the bearings by pressing several times until the proper shim spacing is attained.

11. We didn't want to leave out the lube! This Amsoil extreme-pressure Severe Gear 75W-90 is perfect for cheapskates who don't want to change differential oil more than once a year. The fully synthetic formula features proprietary additives that form an iron-sulfide barrier coating on gear surfaces, providing the ultimate line of defense against wear, pitting, and scoring.

11. We didn't want to leave out the lube! This Amsoil extreme-pressure Severe Gear 75W-90 is perfect for cheapskates who don't want to change differential oil more than once a year. The fully synthetic formula features proprietary additives that form an iron-sulfide barrier coating on gear surfaces, providing the ultimate line of defense against wear, pitting, and scoring.

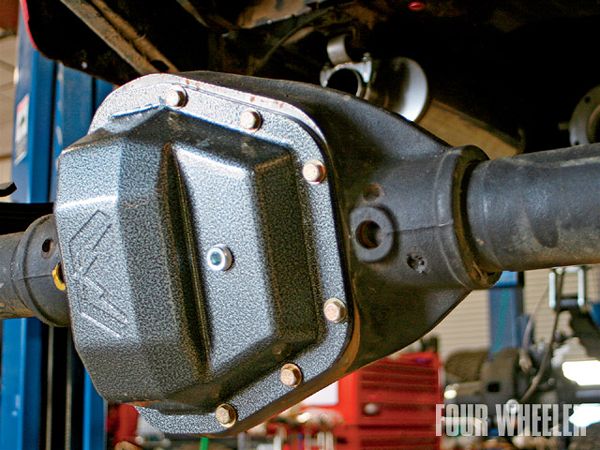

12. This photo shows a tough Fab Fours Dana 60 differential cover fitted to our Dana 70U differential. The only catch here is that this particular cover will not work with gearing that is numerically lower than 4.88:1. This cover runs right in the neighborhood of $200 before tax.

12. This photo shows a tough Fab Fours Dana 60 differential cover fitted to our Dana 70U differential. The only catch here is that this particular cover will not work with gearing that is numerically lower than 4.88:1. This cover runs right in the neighborhood of $200 before tax.

Some may remember this Jeep from the January '09 issue, where we demonstrated how to get ample articulation on a shoestring budget. As you can see, the project is progressing nicely. Eventually this Scrambler will hang with the big dogs and still drive reliably to and from the trailhead.

Some may remember this Jeep from the January '09 issue, where we demonstrated how to get ample articulation on a shoestring budget. As you can see, the project is progressing nicely. Eventually this Scrambler will hang with the big dogs and still drive reliably to and from the trailhead.