It's no secret that the Jeep CJ series offers great off-road potential. The availablity of these vehicles makes it fairly easy to locate and build a cost-effective trail rig. From 1972 through 1986, the primary powerplants were the inline sixes, in 232 and 258 versions, and the V-8 304. Both types of engines command loyal and devoted followers-many who cite the respectable torque and power curves, along with durability and longevity. Personal preferences regarding weight and balance, fuel economy, and other less tangible characteristics always make for some good-natured trailside and campfire debates.

Most Jeep owners agree, though, about the limitations of the undergeared and undersized transmissions available for these vehicles. While a small percentage of these vehicles were offered with optional compound-low four-speeds, the majority, depending upon year of manufacture, contained rather small and light-duty three-speed and lightweight aluminum-cased four- and five-speed gearboxes. All of the three- and four-speed gearboxes have a final geardrive ratio of 1:1, while the five-speed provides an Overdrive Fifth gear. First gear (or low) in these transmissions varies from 2.99 to 4.07. Even the optional heavy-duty T18s provide a marginally acceptable 4.02 First gear.

The First-gear ratio is instrumental in determining the crawl ratio of the vehicle. This ratio determines the potential of the Jeep for rockclimbing and low-speed trail use. Lower ratios mean lower available speed, which can provide better vehicle control, and downhill maneuvers will require little or no braking effort due to the lower gearing. Allowing gears to control descent speed, rather than engaging the brakes and creating a sliding effect, allows for much greater vehicle control. Also, the greatly compounded low gears will allow slower vehicle travel over tough obstacles. The result is less wear and tear on all other systems and passengers, since the Jeep can crawl over and around obstacles instead of using the high-speed "banzai-and-bounce" approach.

The large number of possible transmission swap options has made the swap process popular. While the focus of this article is on manual-transmission options, adapters are available for a wide range of automatics, and performance is the primary concern addressed when considering a transmission upgrade, the monetary expense must be considered as well.

Using a cost-to-benefit ratio scenario helps clarify the options and define the best choice for your particular application. For example, compound-low five- and six-speed transmissions are a possible option, and if your Jeep is required for daily duty as well as off-road adventure, the additional initial cost may be justified. If your Jeep is an occasional driver or strictly for trail use, you can take advantage of combinations that require a much lower initial cost. This particular rig sees only trail use, so taking this into consideration, we opted to seek out a compound low four-speed since an Overdrive gear is not needed. Salvage yards are chock-full of good candidates for this type of swap. T18s, T19s, T98s, SM465s, NP435s, and the like abound, and these units can be found in good condition in the $100 to $300 range.

Doing a little research prior to locating a donor gearbox is time well spent. GM, Ford, Chrysler, International, and other manufacturers have produced versions of the aforementioned trannies. In addition, input shaft lengths and spline sizes, gear ratios, shift patterns, and bolt patterns can vary, based upon the original application. Those mated to six-cylinder engines may have had different length input shafts than those mated to V-8s. Advance Adapters can provide a wealth of knowledge in its buyer's guide and installation manual. The Advance Adapters booklets offer all of the detailed information necessary to locate and identify almost any desired donor gearbox.

The Ford version of the New Process (NP) 435 was singled out for this retrofit for a number of reasons. It was used in the F-series trucks and Broncos from 1968 to 1983. It is a heavy-duty cast-iron-cased unit that has a 6.70 First gear and an 8.02 Reverse. The NP435 was produced in both two- and four-wheel-drive models. The NP435 also shares a bellhousing bolt pattern identical to those used in Jeep CJs from 1976 to 1986. It can be identified by an aluminum top cover with the "NP" symbol on it. The case is 10.875 inches in length, and has a casting number of C96391 on the left side.

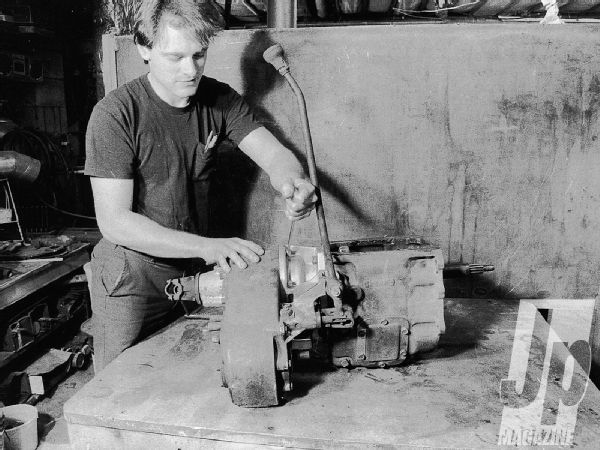

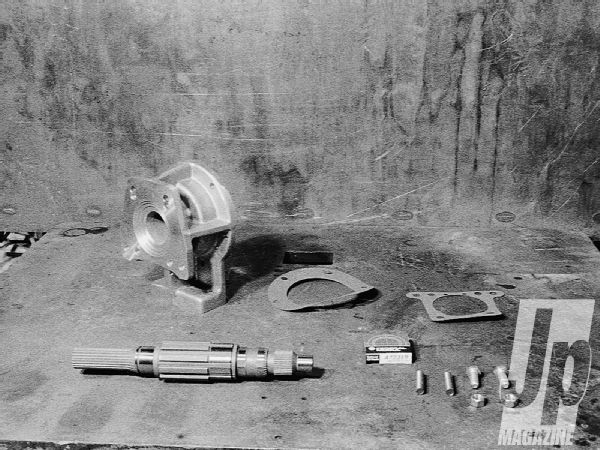

The Advance Adapter kit works with both the two- and four-wheel-drive gearboxes, and includes a new mainshaft, adapter housing, gaskets, seals, and instructions.

The Advance Adapter kit works with both the two- and four-wheel-drive gearboxes, and includes a new mainshaft, adapter housing, gaskets, seals, and instructions.

The NP435 allows the retainment of the stock bellhousing, flywheel, starter, clutch system, and clutch linkage. In some installations even the stock length driveshafts can be re-used. Some modifications to the transmission crossmember may be required, and can vary upon specific installation.

We used the Advanced Adapters kit (PN 50-3801) to mate the NP435 to this '80 CJ-5 Dana 300 transfer case, and also opted for the special pilot bushing (PN 716156). A kit to fit the earlier Dana 18 and 20 transfer cases is also available (PN 50-6102). The adapter kit installation process is nearly identical in both instances.

The total cost of this upgrade compares favorably to the inevitable rebuilding/replacement of the overmatched T176 originally outfitted in our CJ-5. The strength increase of the NP435 swap is greatly enhanced by the improved crawl ratio as well. The T176 First gear of 3.82, multiplied by the Dana 300 low of 2.6, multiplied by the 3.54 differential ratio, provided a final ratio of a marginally acceptable 35.15:1. The NP435 First gear of 6.70, times 2.6, times 3.54, provided a much-improved final ratio of 61.67:1. The NP435 swap nearly doubled the crawl ratio in lower gears and ranges, yet allowed the retainment of the same Fourth-gear 1:1 ratio as the old T176.

PhotosView Slideshow