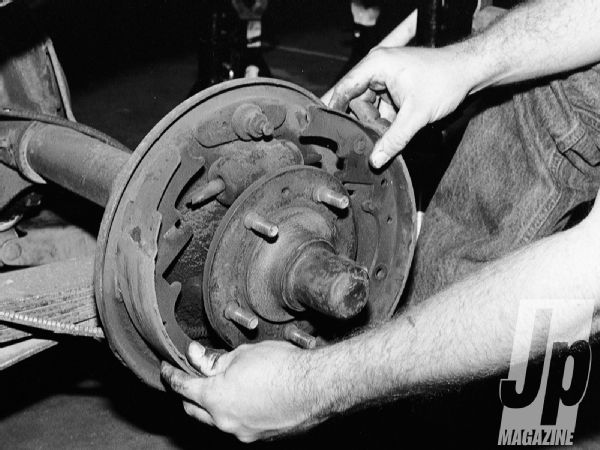

For those who haven't worked on drum brakes before, the task can seem quite daunting. But, fortunately, that tangle of springs, pins, cables and all looks worse than it really is.

For this story, we focus our how-to exposé on the rear brakes because, due to the addition of the parking-brake system, they're more complicated than the front. Tool requirements are minimal for this job, although a quality set of drum brake tools, like those we got from Eastwood, can make the job a bit easier.

As for replacement parts, you can get just about everything in a CJ's drum brake system from Savanna Jones, our source for this operation. Since our Jeep has reached a healthy 22-plus years of age, we thought it wise to replace everything we could-especially the springs, as these can rust over time and possibly break (parking-brake strut springs, for example, are notorious for breaking).

Savanna Jones supplied everything needed to do a thorough rebuild on Project Ridge Runner's drum brakes: shoes, cables, adjusting screws, springs, cable guides, wheel cylinders, and assorted small parts.

Savanna Jones supplied everything needed to do a thorough rebuild on Project Ridge Runner's drum brakes: shoes, cables, adjusting screws, springs, cable guides, wheel cylinders, and assorted small parts.

Follow the photos as we take you through the joys of rebuilding drum brakes.

PhotosView Slideshow